- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Does Nitinol Rust?

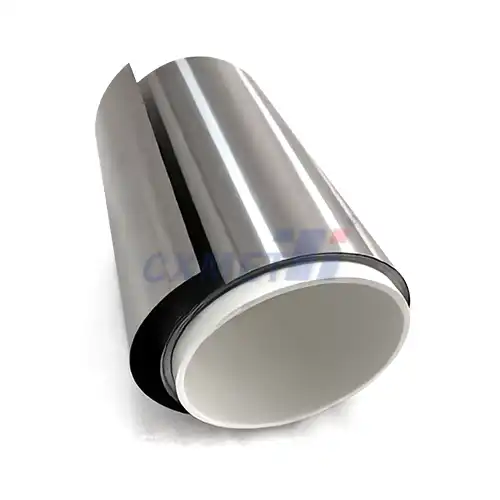

Nitinol, a remarkable alloy of nickel and titanium, has garnered significant attention in various industries due to its unique properties. One of the most common questions about this material is whether it rusts. To address this concern, it's essential to understand that Nitinol does not rust in the traditional sense. Unlike iron-based alloys, Nitinol forms a protective oxide layer on its surface when exposed to oxygen, which prevents further corrosion. This characteristic makes Nitinol highly resistant to corrosion in many environments, including saltwater and bodily fluids. However, it's important to note that while Nitinol Bar doesn't rust, it can still be susceptible to other forms of corrosion under certain conditions.

What are the main applications of nitinol bar stock?

Nitinol bar stock has found its way into a wide array of applications across multiple industries, thanks to its exceptional properties. The unique combination of shape memory and superelasticity makes Nitinol an ideal material for various innovative products and solutions.

In the medical field, Nitinol bar stock is extensively used in the production of surgical instruments, implants, and stents. Surgical tools made from Nitinol can be designed to change shape when exposed to body temperature, allowing for minimally invasive procedures. For instance, Nitinol guidewires used in catheterization procedures can navigate through complex vascular pathways with ease due to their superelastic properties.

Orthodontic archwires made from Nitinol provide consistent, gentle forces for tooth movement, reducing patient discomfort and treatment time. These wires can maintain their shape and apply constant pressure over extended periods, making them more effective than traditional stainless steel wires.

In the aerospace industry, Nitinol bar stock is utilized in the creation of actuators and fasteners. The shape memory effect of Nitinol allows for the development of compact and lightweight actuators that can be used in aircraft control surfaces or satellite deployment mechanisms. Nitinol fasteners can be designed to tighten or loosen in response to temperature changes, providing secure connections in challenging environments.

The automotive sector has also embraced Nitinol bar stock for various applications. Engine valves made from Nitinol can improve fuel efficiency and reduce emissions by adapting to different operating temperatures. Additionally, Nitinol-based impact absorbers can enhance vehicle safety by absorbing and dissipating energy during collisions.

In the consumer electronics industry, Nitinol bar stock is used in the production of antennas, particularly for mobile devices. The superelastic properties of Nitinol allow for the creation of flexible antennas that can withstand repeated bending and twisting without losing their shape or performance.

The versatility of Nitinol bar stock extends to the field of robotics, where it is used in the development of artificial muscles and actuators. These components can mimic the behavior of biological muscles, enabling the creation of more lifelike and efficient robotic systems.

How does the composition of Nitinol affect its properties?

The composition of Nitinol plays a crucial role in determining its properties and behavior. Nitinol is an intermetallic compound consisting primarily of nickel and titanium, with the most common composition being approximately 55% nickel and 45% titanium by weight. However, slight variations in this composition can significantly impact the alloy's characteristics.

The ratio of nickel to titanium in Nitinol directly affects its transformation temperatures, which are critical for its shape memory and superelastic properties. A higher nickel content generally lowers the transformation temperatures, while a higher titanium content raises them. This relationship allows manufacturers to tailor the alloy's composition to suit specific application requirements.

In addition to the primary elements, small amounts of other elements such as copper, iron, or niobium can be added to further modify Nitinol's properties. For example, the addition of copper can improve the stability of the shape memory effect and increase the temperature range over which the alloy exhibits superelasticity.

The composition also influences the mechanical properties of Nitinol. Variations in the nickel-titanium ratio can affect the alloy's strength, ductility, and fatigue resistance. Higher nickel content typically results in increased strength and improved superelastic properties, while higher titanium content can enhance the shape memory effect and improve biocompatibility.

The microstructure of Nitinol, which is closely related to its composition, plays a significant role in determining its behavior. The presence of precipitates, grain size, and crystal orientation can all be influenced by the alloy's composition and processing methods. These factors, in turn, affect the material's transformation characteristics, mechanical properties, and overall performance.

Understanding the relationship between composition and properties is crucial for engineers and designers working with Nitinol bar stock. By carefully controlling the alloy's composition, it's possible to create Nitinol products with specific transformation temperatures, mechanical properties, and performance characteristics tailored to meet the demands of various applications.

What are the challenges in processing Nitinol bar stock?

Processing Nitinol bar stock presents several unique challenges due to the material's distinctive properties and sensitivity to processing conditions. These challenges must be carefully addressed to ensure the production of high-quality Nitinol components with consistent and reliable performance.

One of the primary challenges in processing Nitinol bar stock is controlling the material's microstructure and transformation temperatures. The shape memory and superelastic properties of Nitinol are highly dependent on its crystal structure and the presence of specific phases. Achieving the desired microstructure requires precise control over heat treatment processes, including annealing, aging, and shape-setting treatments. Even small variations in temperature or duration during these processes can significantly affect the final properties of the Nitinol component.

Machining Nitinol bar stock can be particularly challenging due to its high strength, work-hardening tendency, and superelastic behavior. Traditional machining techniques often result in rapid tool wear and poor surface finish. Specialized cutting tools and machining strategies, such as electron discharge machining (EDM) or water jet cutting, are often required to achieve precise and efficient processing of Nitinol components.

The formation of a stable oxide layer on Nitinol surfaces is crucial for its corrosion resistance and biocompatibility. However, this oxide layer can be easily damaged or altered during processing, potentially compromising the material's performance. Careful surface treatment and passivation processes are necessary to ensure the formation of a uniform and stable oxide layer on Nitinol components.

Another significant challenge in processing Nitinol bar stock is maintaining consistent properties throughout the material. Due to its sensitivity to composition and processing conditions, Nitinol can exhibit variations in properties along the length of a bar or between different production batches. This variability can lead to inconsistencies in the performance of finished components, necessitating stringent quality control measures and potentially increasing production costs.

The shape memory effect of Nitinol can also complicate processing and assembly procedures. Components may change shape unexpectedly during machining or heat treatment, requiring careful consideration of the material's behavior throughout the manufacturing process. This characteristic can make it challenging to achieve tight tolerances and consistent geometries in Nitinol parts.

Joining Nitinol to itself or other materials presents another set of challenges. Traditional welding techniques can alter the material's microstructure and properties, potentially compromising its performance. Advanced joining methods, such as laser welding or friction welding, may be required to create reliable and durable connections in Nitinol assemblies.

Despite these challenges, the unique properties of nitinol bar stock continue to drive innovation in various industries. Overcoming these processing hurdles requires a deep understanding of the material's behavior, specialized equipment, and carefully optimized manufacturing processes. As research in Nitinol processing continues to advance, new techniques and methodologies are being developed to address these challenges and expand the potential applications of this remarkable material.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Pelton, A. R., Stöckel, D., & Duerig, T. W. (2000). Medical uses of nitinol. Materials Science Forum, 327, 63-70.

2. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

3. Otsuka, K., & Ren, X. (2005). Physical metallurgy of Ti–Ni-based shape memory alloys. Progress in Materials Science, 50(5), 511-678.

4. Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2012). Manufacturing and processing of NiTi implants: A review. Progress in Materials Science, 57(5), 911-946.

5. Stoeckel, D., Pelton, A., & Duerig, T. (2004). Self-expanding nitinol stents: material and design considerations. European Radiology, 14(2), 292-301.

6. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

7. Favier, D., Liu, Y., & McCormick, P. G. (1993). Three stage transformation behavior in aged NiTi. Scripta Metallurgica et Materialia, 28(6), 669-672.

8. Shabalovskaya, S. A. (2002). Surface, corrosion and biocompatibility aspects of Nitinol as an implant material. Bio-Medical Materials and Engineering, 12(1), 69-109.

9. Buehler, W. J., Gilfrich, J. V., & Wiley, R. C. (1963). Effect of low‐temperature phase changes on the mechanical properties of alloys near composition TiNi. Journal of Applied Physics, 34(5), 1475-1477.

10. Nespoli, A., Besseghini, S., Pittaccio, S., Villa, E., & Viscuso, S. (2010). The high potential of shape memory alloys in developing miniature mechanical devices: A review on shape memory alloy mini-actuators. Sensors and Actuators A: Physical, 158(1), 149-160.