- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does Gr3 Titanium Wire Compare To Gr4 Or Gr5 In Terms Of Strength?

2024-12-07 16:04:19

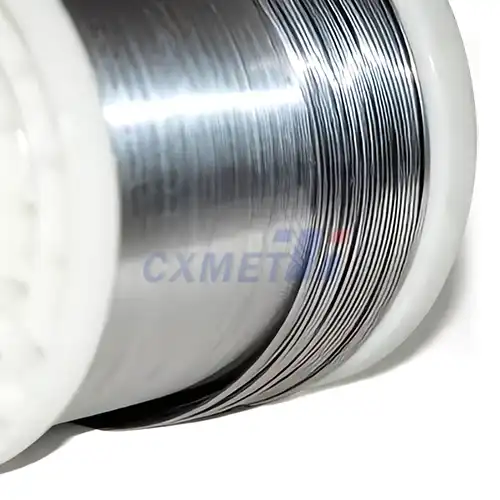

Titanium is a versatile metal known for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. When it comes to titanium wire, different grades offer varying levels of strength and other properties. In this blog post, we'll explore how Grade 3 (Gr3) titanium wire compares to Grade 4 (Gr4) and Grade 5 (Gr5) in terms of strength, and delve into the factors that influence their performance in various applications.

What are the main differences between Gr3, Gr4, and Gr5 titanium alloys?

To understand the strength differences between Gr3, Gr4, and Gr5 titanium wire, it's essential to first examine the composition and characteristics of these alloys. Each grade has its unique properties that make it suitable for specific applications.

Gr3 titanium wire is a commercially pure (CP) titanium with a slightly higher oxygen content than Gr1 and Gr2. It offers a good balance between strength and ductility, making it suitable for applications that require moderate strength and excellent formability. Gr3 titanium typically contains:

- Titanium: Balance

- Oxygen: 0.35% max

- Nitrogen: 0.05% max

- Carbon: 0.08% max

- Hydrogen: 0.015% max

- Iron: 0.30% max

Grade 4 titanium is the strongest of the commercially pure grades. It has a higher oxygen content than Gr3, which contributes to its increased strength. Gr4 titanium is often used in applications that require higher strength while maintaining good corrosion resistance. Its typical composition includes:

- Titanium: Balance

- Oxygen: 0.40% max

- Nitrogen: 0.05% max

- Carbon: 0.08% max

- Hydrogen: 0.015% max

- Iron: 0.50% max

Grade 5 titanium, also known as Ti-6Al-4V, is an alpha-beta alloy and is the most commonly used titanium alloy. It offers the highest strength among the three grades discussed here. Gr5 titanium is widely used in aerospace, medical, and industrial applications due to its excellent mechanical properties. Its composition typically includes:

- Titanium: Balance

- Aluminum: 5.5-6.75%

- Vanadium: 3.5-4.5%

- Oxygen: 0.20% max

- Nitrogen: 0.05% max

- Carbon: 0.08% max

- Hydrogen: 0.015% max

- Iron: 0.40% max

The main differences between these alloys lie in their composition, which directly affects their strength, ductility, and other mechanical properties. Gr3 offers moderate strength with good formability, Gr4 provides higher strength while maintaining the benefits of commercially pure titanium, and Gr5 delivers the highest strength and excellent overall performance.

How do the tensile strengths of Gr3, Gr4, and Gr5 titanium wires compare?

When comparing the strength of Gr3, Gr4, and Gr5 titanium wires, tensile strength is a crucial factor to consider. Tensile strength is the maximum stress that a material can withstand while being stretched before it breaks. Let's examine how these grades compare in terms of tensile strength:

Grade 3 titanium wire typically has a minimum tensile strength of around 450 MPa (65 ksi). This moderate strength level makes it suitable for applications that require a balance between strength and formability. Gr3 titanium wire is often used in marine applications, chemical processing equipment, and some medical implants.

Grade 4 titanium wire offers higher strength compared to Gr3, with a minimum tensile strength of approximately 550 MPa (80 ksi). This increased strength makes Gr4 titanium wire an excellent choice for applications that demand higher load-bearing capabilities while still maintaining the benefits of commercially pure titanium, such as excellent corrosion resistance and biocompatibility. Common applications for Gr4 titanium wire include dental implants, orthopedic screws, and marine hardware.

Grade 5 titanium wire, being an alpha-beta alloy, significantly outperforms both Gr3 and Gr4 in terms of tensile strength. Gr5 titanium wire typically has a minimum tensile strength of around 895 MPa (130 ksi), which is nearly twice that of Gr3. This high strength makes Gr5 titanium wire ideal for applications in aerospace, automotive, and high-performance sports equipment where maximum strength and excellent fatigue resistance are required.

It's important to note that these values are approximate and can vary depending on the specific manufacturing process, heat treatment, and wire diameter. Additionally, the strength of titanium wire can be further enhanced through cold working or other processing techniques.

When selecting the appropriate grade of titanium wire for a specific application, it's crucial to consider not only the tensile strength but also other mechanical properties such as yield strength, elongation, and fatigue resistance. Each grade offers a unique combination of properties that may make it more suitable for certain applications over others.

What factors should be considered when choosing between Gr3, Gr4, and Gr5 titanium wire for specific applications?

Selecting the most appropriate grade of titanium wire for a specific application involves considering various factors beyond just strength. While Gr3, Gr4, and Gr5 titanium wires offer different levels of strength, each grade has its unique set of properties that may make it more suitable for certain applications. Here are some key factors to consider when choosing between these titanium wire grades:

- Strength requirements: As discussed earlier, Gr5 titanium wire offers the highest strength, followed by Gr4 and then Gr3. If maximum strength is the primary concern, Gr5 would be the best choice. However, if moderate strength is sufficient, Gr3 or Gr4 may be more cost-effective options.

- Corrosion resistance: All three grades offer excellent corrosion resistance, but Gr3 and Gr4, being commercially pure titanium, generally provide superior corrosion resistance compared to Gr5. In highly corrosive environments, Gr3 or Gr4 may be preferred.

- Ductility and formability: Gr3 titanium wire typically offers better ductility and formability compared to Gr4 and Gr5. If the application requires significant shaping or bending of the wire, Gr3 may be the most suitable choice.

- Fatigue resistance: Gr5 titanium wire generally exhibits superior fatigue resistance compared to Gr3 and Gr4. For applications involving cyclic loading or repeated stress, Gr5 may be the best option.

- Biocompatibility: All three grades are biocompatible, making them suitable for medical applications. However, Gr4 and Gr5 are more commonly used in medical implants due to their higher strength.

- Weight considerations: While all titanium grades offer an excellent strength-to-weight ratio, Gr5 provides the highest strength for a given weight. In applications where weight is a critical factor, such as aerospace, Gr5 may be preferred.

- Welding and joining: Gr3 and Gr4 are generally easier to weld compared to Gr5. If the application requires extensive welding or joining, the commercially pure grades may be more suitable.

- Cost: Gr3 titanium wire is typically the least expensive, followed by Gr4, with Gr5 being the most costly due to its alloying elements and processing requirements. Budget constraints may influence the choice of grade.

- Temperature resistance: Gr5 titanium wire generally offers better performance at elevated temperatures compared to Gr3 and Gr4. For high-temperature applications, Gr5 may be the most suitable choice.

- Availability and lead times: Gr3 and Gr4 titanium wires are often more readily available than Gr5 due to their wider use in various industries. If quick delivery is a priority, this may influence the selection.

When selecting the appropriate titanium wire grade, it's essential to consider the specific requirements of the application and weigh the pros and cons of each grade. In some cases, a combination of factors may lead to choosing a grade that isn't necessarily the strongest but offers the best overall performance for the intended use.

For example, in marine applications where corrosion resistance is paramount, Gr3 or Gr4 titanium wire may be preferred over the stronger Gr5. In contrast, for aerospace components that require maximum strength and fatigue resistance, Gr5 would likely be the top choice despite its higher cost.

It's also worth noting that in some cases, custom titanium alloys or surface treatments may be developed to meet specific application requirements that cannot be fully satisfied by standard Gr3, Gr4, or Gr5 titanium wires.

Ultimately, consulting with materials engineers or titanium suppliers can provide valuable insights into selecting the most appropriate titanium wire grade for a given application, ensuring optimal performance, cost-effectiveness, and longevity of the final product.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

- ASTM International. (2021). ASTM B348 - Standard Specification for Titanium and Titanium Alloy Bars and Billets.

- Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

- Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

- Lutjering, G., & Williams, J. C. (2007). Titanium. Springer-Verlag Berlin Heidelberg.

- Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Titanium Industries. (n.d.). Titanium Grades. Retrieved from https://www.titanium.com/titanium-grades/

- United Performance Metals. (n.d.). Titanium Grades. Retrieved from https://www.upmet.com/products/titanium/grades

- Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.