- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How is Grade 4 Titanium Round Bar Used in the Aerospace Industry?

2024-09-09 14:33:29

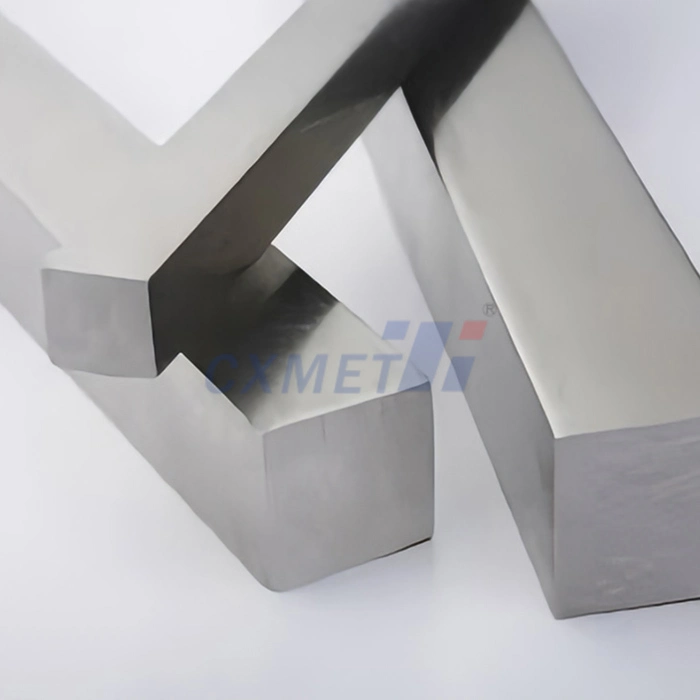

Grade 4 Titanium Round Bar has become an indispensable material in the aerospace industry, revolutionizing the way aircraft and spacecraft components are manufactured. This high-performance alloy, known for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, has found numerous applications in various critical parts of aerospace vehicles. From structural components to engine parts, Grade 4 Titanium Round Bar plays a crucial role in enhancing the performance, durability, and safety of modern aircraft and spacecraft.

What are the key properties of Grade 4 Titanium that make it suitable for aerospace applications?

Grade 4 Titanium, also known as commercially pure (CP) titanium grade 4, possesses a unique combination of properties that make it highly desirable for aerospace applications. Understanding these properties is essential to appreciate why this material has become so prevalent in the industry.

First and foremost, Grade 4 Titanium boasts an impressive strength-to-weight ratio. This characteristic is paramount in aerospace engineering, where every gram of weight matters. The material's high strength allows for the creation of robust components that can withstand the extreme forces experienced during flight, while its relatively low density helps keep the overall weight of the aircraft or spacecraft to a minimum. This balance between strength and weight translates directly into improved fuel efficiency and increased payload capacity, both of which are critical factors in aerospace design.

Corrosion resistance is another key property that sets Grade 4 Titanium apart. The aerospace environment is notoriously harsh, with exposure to various corrosive elements such as saltwater, atmospheric pollutants, and extreme temperatures. Grade 4 Titanium forms a stable, protective oxide layer on its surface when exposed to oxygen, providing excellent resistance to corrosion in most environments. This natural protection eliminates the need for additional protective coatings in many applications, reducing maintenance costs and extending the lifespan of components.

The material's high heat resistance is another crucial factor in its aerospace suitability. Aircraft and spacecraft components often operate under extreme temperature conditions, particularly in engine areas. Grade 4 Titanium maintains its strength and structural integrity at elevated temperatures, making it an ideal choice for parts that are exposed to high heat during operation.

Furthermore, Grade 4 Titanium exhibits excellent fatigue resistance. In aerospace applications, materials are subjected to repeated cycles of stress, which can lead to fatigue failure over time. The superior fatigue properties of Grade 4 Titanium ensure that components can withstand these cyclic loads for extended periods, enhancing the overall safety and reliability of aerospace vehicles.

The biocompatibility of Grade 4 Titanium, while not directly related to its aerospace applications, is worth mentioning as it opens up possibilities for dual-use technologies. This property makes the material safe for use in medical implants and devices, potentially leading to crossover innovations between the aerospace and medical industries.

Lastly, the material's low thermal expansion coefficient is advantageous in aerospace applications. This property ensures dimensional stability across a wide range of temperatures, which is crucial for maintaining precise tolerances in aerospace components.

How does Grade 4 Titanium Round Bar compare to other materials in aircraft manufacturing?

When comparing Grade 4 Titanium Round Bar to other materials commonly used in aircraft manufacturing, several factors come into play, including performance characteristics, cost-effectiveness, and ease of manufacturing.

Aluminum alloys have long been a staple in the aerospace industry due to their low density and good strength-to-weight ratio. However, Grade 4 Titanium outperforms aluminum in several key areas. Titanium has a higher strength-to-weight ratio, better corrosion resistance, and superior heat resistance. While aluminum is lighter, titanium's strength allows for the use of less material, often resulting in components that are just as light but significantly stronger. This is particularly important in high-stress areas of the aircraft where aluminum might not be suitable.

Steel, another common aerospace material, offers high strength but at the cost of increased weight. Grade 4 Titanium provides comparable strength to many steel alloys but at roughly half the weight. This weight saving is crucial in aerospace applications where fuel efficiency is a primary concern. Additionally, titanium's corrosion resistance is superior to that of most steels, reducing the need for protective coatings and lowering maintenance requirements.

Composite materials, such as carbon fiber reinforced polymers (CFRP), have gained popularity in recent years due to their excellent strength-to-weight ratios and design flexibility. While composites can outperform titanium in terms of weight savings in some applications, they often fall short in terms of heat resistance and damage tolerance. Grade 4 Titanium remains the material of choice for components that are exposed to high temperatures or require high impact resistance.

When it comes to cost, Grade 4 Titanium is generally more expensive than aluminum or steel. However, its long-term cost-effectiveness often justifies the initial investment. The extended lifespan of titanium components, reduced maintenance requirements, and potential weight savings (leading to improved fuel efficiency) can result in significant cost savings over the life of an aircraft.

Manufacturing processes also play a role in material selection. While titanium can be more challenging to machine than aluminum or steel due to its hardness and low thermal conductivity, advancements in manufacturing technologies have made working with titanium more accessible. Techniques such as near-net-shape forming and additive manufacturing have helped to reduce waste and processing time, making titanium components more economically viable.

What are the challenges in machining Grade 4 Titanium Round Bar for aerospace components?

Machining Grade 4 Titanium Round Bar for aerospace components presents several unique challenges that manufacturers must overcome to produce high-quality parts efficiently. Understanding these challenges is crucial for developing effective machining strategies and ensuring the production of components that meet the stringent requirements of the aerospace industry.

One of the primary challenges in machining Grade 4 Titanium is its low thermal conductivity. This property causes heat to build up quickly at the cutting edge during machining operations. Excessive heat can lead to rapid tool wear, degradation of the machined surface, and even changes in the material's microstructure, potentially affecting its performance characteristics. To address this issue, manufacturers must employ specialized cooling techniques, such as high-pressure coolant systems or cryogenic cooling, to effectively dissipate heat from the cutting zone.

The material's high strength and hardness, while beneficial for the final component, make it resistant to cutting and forming operations. This resistance results in high cutting forces during machining, which can lead to tool deflection and vibration, affecting the dimensional accuracy and surface finish of the machined parts. To combat this, rigid machine setups and specialized cutting tools with geometry designed specifically for titanium machining are often required.

Another significant challenge is the material's tendency to work harden during machining. As the titanium is cut, the mechanical stress can cause the surface layer to harden, making subsequent passes more difficult and potentially leading to rapid tool wear. This phenomenon necessitates careful selection of cutting parameters and tool geometries to minimize work hardening and maintain consistent machining conditions throughout the process.

The chemical reactivity of titanium at high temperatures poses another challenge. During high-speed machining operations, the elevated temperatures can cause titanium to react with the cutting tool material, leading to accelerated tool wear and potential contamination of the machined surface. This reactivity limits the choice of cutting tool materials and coatings, often necessitating the use of specialized, more expensive tooling solutions.

Tool life is a constant concern when machining Grade 4 Titanium. The combination of high strength, low thermal conductivity, and chemical reactivity leads to accelerated tool wear compared to machining other materials. This results in frequent tool changes, which can increase production costs and lead times. Manufacturers must carefully optimize cutting parameters and employ advanced tool materials and coatings to extend tool life and improve overall machining efficiency.

The springback effect, where the material elastically returns to its original shape after deformation, can be particularly pronounced in titanium machining. This effect can lead to dimensional inaccuracies and difficulties in achieving tight tolerances. Compensation strategies, such as over-bending or stress-relief heat treatments, may be necessary to counteract springback and ensure the final component meets specifications.

Lastly, the high cost of Grade 4 Titanium Round Bar itself adds pressure to the machining process. With raw material costs being a significant portion of the overall component cost, minimizing waste and optimizing material utilization become critical. This often requires advanced programming techniques, such as nesting and toolpath optimization, to maximize the number of components that can be produced from a given piece of stock material.

In conclusion, Grade 4 Titanium Round Bar has become an integral material in the aerospace industry due to its exceptional properties and performance characteristics. Its use in various critical components has significantly contributed to advancements in aircraft and spacecraft design, enabling the creation of lighter, stronger, and more efficient aerospace vehicles. While challenges in machining this material exist, ongoing research and technological advancements continue to improve manufacturing processes, making Grade 4 Titanium an increasingly attractive option for aerospace applications. As the industry continues to push the boundaries of performance and efficiency, the role of Grade 4 Titanium Round Bar in aerospace manufacturing is likely to grow, driving innovation and shaping the future of air and space travel.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Lutjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

2. Boyer, R. R. (1996). An overview on the use of titanium in the aerospace industry. Materials Science and Engineering: A, 213(1-2), 103-114.

3. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

4. Ezugwu, E. O., & Wang, Z. M. (1997). Titanium alloys and their machinability—a review. Journal of Materials Processing Technology, 68(3), 262-274.

5. Inagaki, I., Takechi, T., Shirai, Y., & Ariyasu, N. (2014). Application and features of titanium for the aerospace industry. Nippon Steel & Sumitomo Metal Technical Report, 106, 22-27.

6. Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2013). Properties and applications of titanium alloys: a brief review. Reviews on Advanced Materials Science, 32(2), 133-148.

7. Donachie, M. J. (2000). Titanium: a technical guide. ASM international.

8. Yang, X., & Liu, C. R. (1999). Machining titanium and its alloys. Machining Science and Technology, 3(1), 107-139.

9. Jaffery, S. I., & Mativenga, P. T. (2009). Assessment of the machinability of Ti-6Al-4V alloy using the wear map approach. The International Journal of Advanced Manufacturing Technology, 40(7-8), 687-696.

10. Ulutan, D., & Ozel, T. (2011). Machining induced surface integrity in titanium and nickel alloys: A review. International Journal of Machine Tools and Manufacture, 51(3), 250-280.