- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

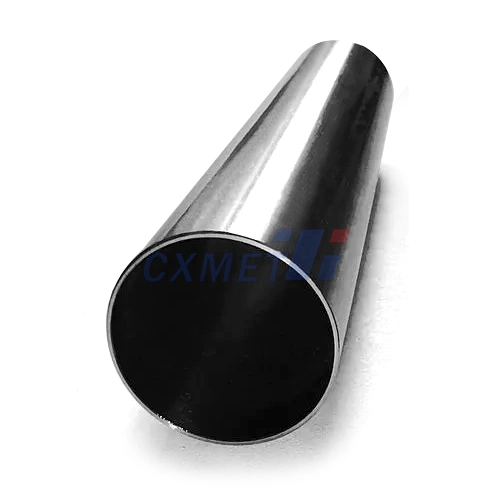

Is GR1 Titanium Seamless Tube the Best?

GR1 titanium seamless tube is widely recognized in various industries for its exceptional properties and versatile applications. As a high-performance material, it offers a unique combination of strength, corrosion resistance, and lightweight characteristics. However, determining whether it's the "best" option depends on specific application requirements and considerations. This blog post will explore the key aspects of GR1 titanium seamless tube and address some common questions to help you make an informed decision.

What are the advantages of using GR1 titanium seamless tube?

GR1 titanium seamless tube, also known as Grade 1 titanium, offers numerous advantages that make it a popular choice in various industries. Its remarkable properties contribute to its widespread use and reputation as a premium material. Let's delve into the key benefits of using GR1 titanium seamless tube:

1. Exceptional Corrosion Resistance: One of the most significant advantages of GR1 titanium seamless tube is its outstanding corrosion resistance. It forms a stable, protective oxide layer on its surface when exposed to air or moisture, providing excellent resistance to various corrosive environments. This characteristic makes it ideal for applications in marine, chemical processing, and aerospace industries where exposure to harsh conditions is common.

2. High Strength-to-Weight Ratio: GR1 titanium seamless tube boasts an impressive strength-to-weight ratio, making it significantly lighter than many other metals while maintaining excellent mechanical properties. This attribute is particularly valuable in aerospace and automotive applications, where weight reduction is crucial for improved fuel efficiency and performance.

3. Biocompatibility: The biocompatibility of GR1 titanium seamless tube is another notable advantage. It is non-toxic and well-tolerated by the human body, making it an excellent choice for medical implants, surgical instruments, and other biomedical applications. Its resistance to bodily fluids and tissues contributes to its long-term stability in biological environments.

4. Temperature Resistance: GR1 titanium seamless tube exhibits good performance across a wide range of temperatures. It maintains its strength and structural integrity at both low and high temperatures, making it suitable for applications in cryogenic systems and heat exchangers.

5. Excellent Formability: Despite its strength, GR1 titanium seamless tube is relatively easy to form and shape. This characteristic allows for greater design flexibility and ease of manufacturing in various applications, from simple tubing to complex components.

6. Low Thermal Expansion: The material's low coefficient of thermal expansion ensures dimensional stability across temperature changes, making it valuable in precision engineering and applications where thermal cycling is a concern.

7. Non-Magnetic Properties: GR1 titanium seamless tube is non-magnetic, which is advantageous in applications where magnetic interference must be minimized, such as in certain medical devices or scientific instruments.

8. Aesthetic Appeal: The natural silver-gray color of GR1 titanium seamless tube, combined with its ability to take on various finishes, makes it an attractive option for architectural and design applications where aesthetics are important.

9. Long-Term Cost-Effectiveness: While the initial cost of GR1 titanium seamless tube may be higher than some alternatives, its durability, longevity, and low maintenance requirements often result in lower life-cycle costs, making it a cost-effective choice in the long run.

10. Environmentally Friendly: Titanium is 100% recyclable and abundant in nature. The use of GR1 titanium seamless tube can contribute to sustainable practices and reduce environmental impact in various industries.

These advantages collectively make GR1 titanium seamless tube a versatile and highly sought-after material across numerous applications. However, it's important to note that the suitability of GR1 titanium seamless tube for a specific application should be evaluated based on the particular requirements and constraints of each project.

How does GR1 titanium seamless tube compare to other materials?

When considering the use of GR1 titanium seamless tube, it's essential to understand how it compares to other materials commonly used in similar applications. This comparison will help highlight the unique properties of GR1 titanium and assist in determining whether it's the best choice for a specific project. Let's examine how GR1 titanium seamless tube stacks up against some of its main competitors:

1. GR1 Titanium vs. Stainless Steel:

Stainless steel is often considered an alternative to titanium due to its corrosion resistance and strength. However, GR1 titanium seamless tube offers several advantages:

- Weight: Titanium is approximately 45% lighter than stainless steel, making it preferable in weight-sensitive applications.

- Corrosion Resistance: While both materials resist corrosion, titanium generally outperforms stainless steel in more aggressive environments, particularly in seawater and chemical processing applications.

- Strength-to-Weight Ratio: Titanium's superior strength-to-weight ratio allows for thinner wall thicknesses and lighter components without sacrificing structural integrity.

- Biocompatibility: Titanium is more biocompatible than stainless steel, making it the preferred choice for medical implants and devices.

2. GR1 Titanium vs. Aluminum:

Aluminum is another lightweight metal often used in aerospace and automotive industries. Comparing it to GR1 titanium:

- Strength: Titanium is significantly stronger than aluminum, allowing for smaller, more compact designs.

- Temperature Resistance: Titanium maintains its properties at higher temperatures than aluminum, making it more suitable for high-temperature applications.

- Corrosion Resistance: While both metals form protective oxide layers, titanium's layer is more stable and provides better protection in harsh environments.

- Fatigue Resistance: Titanium exhibits superior fatigue resistance compared to aluminum, leading to longer component life in cyclic loading conditions.

3. GR1 Titanium vs. Other Titanium Grades:

Within the titanium family, GR1 has its own unique place:

- Purity: GR1 is the purest form of commercially available titanium, with minimal alloying elements.

- Ductility: It offers excellent ductility and formability, making it ideal for applications requiring complex shapes or extensive forming.

- Strength: While not as strong as higher-grade titanium alloys, GR1 provides a good balance of strength and workability for many applications.

- Cost: GR1 is generally less expensive than higher-grade titanium alloys, making it a cost-effective choice when extreme strength is not required.

4. GR1 Titanium vs. Composite Materials:

Composite materials, such as carbon fiber reinforced polymers, are increasingly used in high-performance applications:

- Weight: While composites can be lighter than titanium in some cases, titanium often provides a better balance of weight and strength across a wider range of applications.

- Temperature Resistance: Titanium outperforms many composites in high-temperature environments.

- Repairability: Titanium components are generally easier to repair and maintain compared to composite structures.

- Environmental Resistance: Titanium offers better resistance to environmental factors such as UV radiation and moisture absorption.

5. GR1 Titanium vs. Nickel Alloys:

Nickel alloys are known for their high-temperature performance and corrosion resistance:

- Weight: Titanium is significantly lighter than nickel alloys, offering weight savings in aerospace and industrial applications.

- Cost: While both materials can be expensive, titanium is often more cost-effective in the long term due to its longer service life and lower maintenance requirements.

- Biocompatibility: Titanium is more biocompatible than nickel alloys, which can cause allergic reactions in some individuals.

When comparing GR1 titanium seamless tube to other materials, it's clear that its unique combination of properties makes it an excellent choice for many applications. However, the "best" material always depends on the specific requirements of each project, including factors such as operating environment, mechanical loads, weight constraints, and budget considerations. While GR1 titanium seamless tube excels in many areas, engineers and designers must carefully evaluate these factors to determine if it's the optimal choice for their particular application.

What are the main applications of GR1 titanium seamless tube?

GR1 titanium seamless tube finds its way into a wide array of applications across various industries due to its unique combination of properties. Understanding these applications can provide insight into the versatility and value of this material. Let's explore some of the main areas where GR1 titanium seamless tube is commonly used:

1. Aerospace Industry:

In aerospace applications, the lightweight and high strength properties of GR1 titanium seamless tube are particularly valuable:

- Hydraulic and pneumatic systems in aircraft

- Fuel lines and cooling systems

- Structural components in spacecraft

- Engine parts and exhaust systems

2. Medical and Biomedical Field:

The biocompatibility and corrosion resistance of GR1 titanium make it an excellent choice for medical applications:

- Surgical instruments and tools

- Dental implants and orthodontic devices

- Prosthetic joints and bone replacements

- Medical device casings and components

3. Chemical Processing Industry:

The exceptional corrosion resistance of GR1 titanium seamless tube is crucial in chemical processing:

- Heat exchangers and condensers

- Reaction vessels and storage tanks

- Piping systems for corrosive chemicals

- Distillation columns and evaporators

4. Marine and Offshore Applications:

In marine environments, the resistance to saltwater corrosion is a key advantage:

- Desalination plant components

- Offshore oil and gas platform equipment

- Marine research instruments

- Boat and ship fittings

5. Energy Sector:

GR1 titanium seamless tube plays a role in various energy-related applications:

- Geothermal power plant heat exchangers

- Nuclear power plant components

- Solar panel frames and supports

- Hydrogen fuel cell components

6. Automotive Industry:

While not as common as in aerospace, titanium is used in high-performance automotive applications:

- Exhaust systems for racing cars

- Suspension components

- Valve springs and connecting rods

- Turbocharger wheels

7. Sports and Recreation:

The strength-to-weight ratio of titanium makes it popular in sporting goods:

- Bicycle frames and components

- Golf club heads and shafts

- Tennis racket frames

- Camping and hiking equipment

8. Architecture and Design:

The aesthetic appeal and durability of titanium are valued in architectural applications:

- Decorative facade elements

- Roofing materials

- Structural support in modern buildings

- Sculptures and art installations

These applications demonstrate the versatility and importance of GR1 titanium seamless tube across multiple industries. Its unique properties often make it the material of choice where a combination of strength, light weight, corrosion resistance, and biocompatibility is required. However, it's important to note that the specific grade of titanium used may vary depending on the exact requirements of each application, and GR1 is often chosen for its excellent formability and corrosion resistance when extreme strength is not the primary concern.

In conclusion, while GR1 titanium seamless tube may not be universally "the best" for every application, its exceptional properties make it a top contender in many fields. Its combination of strength, light weight, corrosion resistance, and biocompatibility offers solutions to complex engineering challenges across various industries. When considering whether GR1 titanium seamless tube is the best choice for a specific application, it's crucial to weigh its advantages against the particular requirements of the project, including performance needs, environmental conditions, and economic factors. By understanding its properties, comparisons with other materials, and range of applications, engineers and designers can make informed decisions about incorporating GR1 titanium seamless tube into their projects.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM International. (2021). "Standard Specification for Titanium and Titanium Alloy Seamless Pipe."

2. Boyer, R., Welsch, G., & Collings, E. W. (1994). "Materials Properties Handbook: Titanium Alloys." ASM International.

3. Donachie, M. J. (2000). "Titanium: A Technical Guide." ASM International.

4. Leyens, C., & Peters, M. (Eds.). (2003). "Titanium and Titanium Alloys: Fundamentals and Applications." John Wiley & Sons.

5. Lutjering, G., & Williams, J. C. (2007). "Titanium." Springer Science & Business Media.

6. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, 5(6), 419-427.

7. Rack, H. J., & Qazi, J. I. (2006). "Titanium alloys for biomedical applications." Materials Science and Engineering: C, 26(8), 1269-1277.

8. Schutz, R. W., & Watkins, H. B. (1998). "Recent developments in titanium alloy application in the energy industry." Materials Science and Engineering: A, 243(1-2), 305-315.

9. Titanium Industries. (2022). "Grade 1 Titanium Properties." Retrieved from [titanium.com]

10. Williams, J. C., & Starke Jr, E. A. (2003). "Progress in structural materials for aerospace systems." Acta Materialia, 51(19), 5775-5799.