- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is Gr1 Titanium Wire Corrosion-Resistant?

2024-12-04 11:20:54

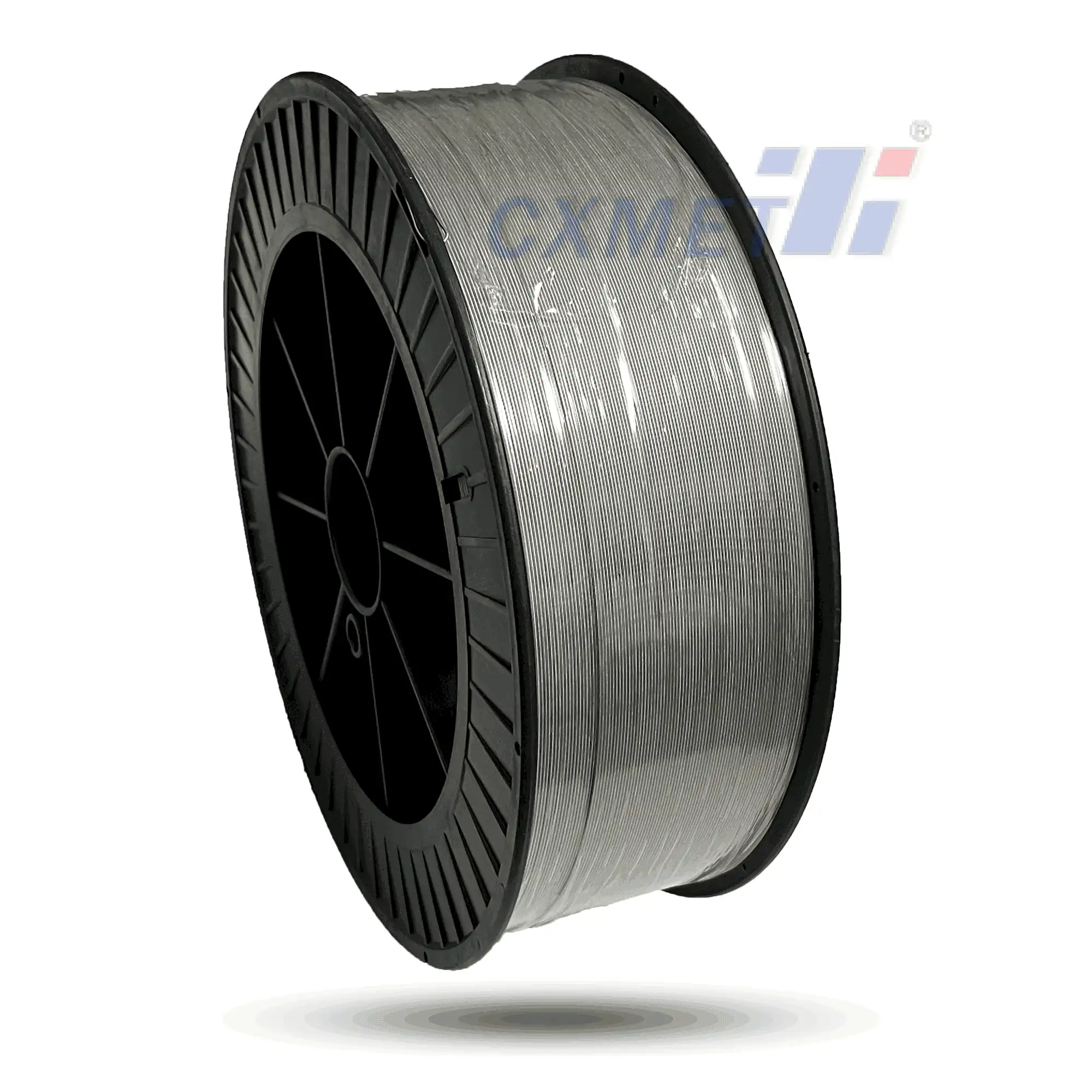

Gr1 Titanium Wire, also known as Grade 1 Titanium Wire, is renowned for its exceptional corrosion resistance. This characteristic makes it a popular choice in various industries, including aerospace, medical, and marine applications. The corrosion resistance of Gr1 Titanium Wire is attributed to its ability to form a stable, protective oxide layer on its surface when exposed to oxygen. This natural phenomenon, known as passivation, provides a barrier against corrosive environments, making Gr1 Titanium Wire an excellent choice for applications where longevity and durability are crucial.

What are the main properties of Gr1 Titanium Wire?

Gr1 Titanium Wire possesses a unique combination of properties that make it highly desirable in various applications. Some of the main properties include:

- Excellent Corrosion Resistance: As mentioned earlier, Gr1 Titanium Wire forms a protective oxide layer, providing superior resistance to corrosion in various environments, including saltwater, acids, and industrial chemicals.

- High Strength-to-Weight Ratio: Despite its lightweight nature, Gr1 Titanium Wire offers impressive strength, making it ideal for applications where weight reduction is crucial without compromising structural integrity.

- Biocompatibility: Gr1 Titanium Wire is non-toxic and compatible with human tissue and bone, making it an excellent choice for medical implants and devices.

- Low Thermal Expansion: The wire exhibits minimal expansion and contraction with temperature changes, ensuring dimensional stability in various operating conditions.

- Non-Magnetic Properties: Gr1 Titanium Wire is non-magnetic, making it suitable for applications where magnetic interference is a concern.

- High Melting Point: With a melting point of approximately 1668°C (3034°F), Gr1 Titanium Wire maintains its structural integrity at high temperatures.

- Excellent Fatigue Resistance: The wire demonstrates superior resistance to cyclic loading, making it ideal for applications involving repeated stress.

- Low Modulus of Elasticity: This property allows for greater flexibility and resilience compared to many other metals.

These properties combine to make Gr1 Titanium Wire an exceptional material for a wide range of applications, from aerospace components to medical implants and marine equipment. Its versatility and durability continue to drive its adoption across various industries, where reliability and longevity are paramount.

How does Gr1 Titanium Wire compare to other grades of titanium?

Gr1 Titanium Wire, while excellent in its own right, is part of a family of titanium grades, each with its unique characteristics. Understanding how Gr1 compares to other grades can help in selecting the most appropriate material for specific applications. Here's a comparison of Gr1 Titanium Wire with other common titanium grades:

- Grade 1 vs. Grade 2 Titanium: Grade 1 (Gr1) is the purest form of commercially pure titanium, with the lowest strength but highest ductility among the unalloyed grades. Grade 2 has slightly higher strength and lower ductility than Grade 1 but is still considered commercially pure.

- Grade 1 vs. Grade 3 and 4 Titanium: Grades 3 and 4 are also commercially pure but have progressively higher strength and lower ductility compared to Grade 1. They contain slightly higher amounts of oxygen, which increases strength but reduces ductility.

- Grade 1 vs. Ti-6Al-4V (Grade 5): Ti-6Al-4V is an alloy containing 6% aluminum and 4% vanadium. It offers significantly higher strength than Grade 1 but is less ductile and slightly less corrosion-resistant in some environments.

- Corrosion Resistance: While all titanium grades offer excellent corrosion resistance, Grade 1 is often considered the most resistant due to its high purity. However, the difference in corrosion resistance between commercially pure grades (1-4) is generally minimal in most environments.

- Weldability: Grade 1 Titanium Wire is the most weldable among titanium grades due to its high purity and ductility. Higher grades and alloys may require more specialized welding techniques.

- Cost: Generally, Grade 1 Titanium Wire is more expensive than higher grades due to its higher purity and more stringent production requirements.

In summary, while Gr1 Titanium Wire offers the highest purity and ductility among titanium grades, it has the lowest strength. Its exceptional corrosion resistance and biocompatibility make it ideal for applications where these properties are critical, such as in the chemical processing industry or for certain medical implants. However, for applications requiring higher strength, other grades or titanium alloys might be more suitable.

What are the main applications of Gr1 Titanium Wire?

Gr1 Titanium Wire finds applications across various industries due to its unique combination of properties. Some of the main applications include:

- Medical and Dental Industry:

- Surgical implants and devices

- Dental implants and orthodontic wires

- Prosthetics

- Aerospace Industry:

- Aircraft components

- Spacecraft parts

- Fasteners and connectors

- Chemical Processing Industry:

- Heat exchangers

- Reaction vessels

- Pipelines and valves

- Marine Industry:

- Boat fittings and hardware

- Underwater equipment

- Desalination plants

- Automotive Industry:

- Exhaust systems

- Valve springs

- Performance parts

- Jewelry and Accessories:

- Body piercings

- Hypoallergenic jewelry

- Watches

- Sports and Recreation:

- Bicycle frames and components

- Golf club heads

- Camping and outdoor equipment

- Energy Sector:

- Geothermal wells

- Oil and gas exploration equipment

- Power generation components

The versatility of Gr1 Titanium Wire is evident in its wide range of applications. Its use in the medical field is particularly noteworthy, where its biocompatibility and corrosion resistance are crucial for long-term implants and devices. In the aerospace industry, the high strength-to-weight ratio of Gr1 Titanium Wire contributes to fuel efficiency and performance improvements.

In chemical processing, the wire's resistance to various corrosive substances makes it an ideal choice for equipment that needs to withstand harsh environments. The marine industry benefits from its resistance to saltwater corrosion, while the automotive sector leverages its strength and heat resistance for high-performance applications.

The use of Gr1 Titanium Wire in jewelry and body piercings showcases its hypoallergenic properties, making it suitable for those with sensitive skin or metal allergies. In sports and recreation, its lightweight nature combined with strength makes it perfect for high-performance equipment.

As technology advances and new applications emerge, the use of Gr1 Titanium Wire is likely to expand further, particularly in areas where its unique combination of properties can provide significant advantages over traditional materials.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

- ASTM International. (2021). Standard Specification for Titanium and Titanium Alloy Wire.

- Lutjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

- Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH.

- Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

- Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

- Titanium Information Group. (2022). Titanium Applications.

- Froes, F. H. (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Schutz, R. W., & Watkins, H. B. (1998). Recent developments in titanium alloy application in the energy industry. Materials Science and Engineering: A, 243(1-2), 305-315.

- Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.