- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is Gr23 Titanium Wire Safe?

Gr23 titanium wire, also known as Ti-6Al-4V ELI (Extra Low Interstitial), is a high-purity variant of the popular Ti-6Al-4V alloy. This material is widely used in various industries, including medical, aerospace, and marine applications, due to its excellent combination of strength, corrosion resistance, and biocompatibility. However, questions about its safety often arise, particularly in medical and consumer applications. In this article, we'll explore the safety aspects of Gr23 titanium wire and address some common concerns.

What are the properties of Gr23 Titanium Wire?

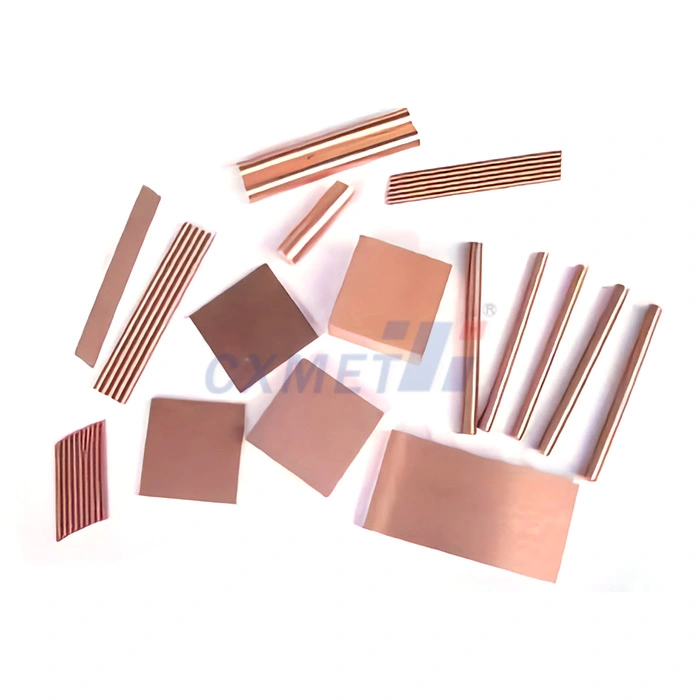

Gr23 titanium wire, or Ti-6Al-4V ELI, is a high-performance alloy that offers a unique combination of properties, making it valuable for various applications. Its composition consists of titanium (Ti) as the base element, with 6% aluminum (Al) and 4% vanadium (V) as alloying elements. The "ELI" designation indicates that this grade has extra low interstitial elements, resulting in improved ductility and fracture toughness compared to standard Ti-6Al-4V.

Key properties of Gr23 titanium wire include:

1. High strength-to-weight ratio: Gr23 titanium wire offers excellent strength while being significantly lighter than many other metals, including steel and nickel alloys. This property makes it ideal for applications where weight reduction is crucial, such as in aerospace and automotive industries.

2. Corrosion resistance: Titanium alloys, including Gr23, are known for their exceptional corrosion resistance. They form a stable, protective oxide layer on their surface when exposed to oxygen, providing excellent resistance to various corrosive environments, including saltwater and bodily fluids.

3. Biocompatibility: Gr23 titanium wire is highly biocompatible, meaning it is well-tolerated by the human body and does not cause adverse reactions when used in medical implants or devices. This property is crucial for its use in orthopedic implants, dental implants, and other medical applications.

4. Low thermal expansion: Compared to many other metals, Gr23 titanium wire has a relatively low coefficient of thermal expansion. This property makes it suitable for applications where dimensional stability over a range of temperatures is important.

5. Excellent fatigue resistance: The alloy demonstrates superior fatigue strength, allowing it to withstand repeated cyclic loading without failure. This characteristic is particularly valuable in aerospace and medical applications where components are subjected to repeated stress.

These properties contribute to the wide-ranging applications of Gr23 titanium wire, from critical aerospace components to life-saving medical implants. However, it's important to note that while these properties generally contribute to the safety of the material, proper processing, handling, and application-specific considerations are crucial to ensure its safe use in various contexts.

How does Gr23 Titanium Wire compare to other medical-grade materials?

When comparing Gr23 titanium wire to other medical-grade materials, it's essential to consider various factors such as biocompatibility, mechanical properties, corrosion resistance, and long-term performance. Gr23 titanium wire, also known as Ti-6Al-4V ELI, is often compared to other materials commonly used in medical applications, including stainless steel, cobalt-chromium alloys, and other grades of titanium.

- Biocompatibility:

Gr23 titanium wire excels in biocompatibility, which is crucial for medical implants and devices. The human body generally tolerates titanium exceptionally well, with minimal risk of allergic reactions or rejection. The oxide layer that forms on the surface of titanium alloys provides a stable interface with biological tissues, promoting osseointegration in orthopedic and dental implants.

Compared to stainless steel, Gr23 titanium wire has a significant advantage in terms of biocompatibility. While some grades of stainless steel (e.g., 316L) are considered biocompatible, they may still pose risks of allergic reactions in some patients, particularly those sensitive to nickel. Cobalt-chromium alloys, while also biocompatible, may release metal ions over time, which can be a concern for long-term implants.

- Mechanical Properties:

Gr23 titanium wire offers an excellent balance of strength and ductility. Its strength-to-weight ratio is superior to that of stainless steel and many other alloys, making it ideal for applications where weight reduction is crucial, such as in spinal implants or prosthetics. The fatigue resistance of Gr23 titanium wire is also exceptional, which is vital for implants subjected to cyclic loading, like hip or knee replacements.

Stainless steel, while strong, is significantly heavier than titanium alloys. This can be a disadvantage in applications where weight is a critical factor. Cobalt-chromium alloys offer high strength and excellent wear resistance, making them suitable for joint replacement components, but they are also heavier than titanium alloys.

- Corrosion Resistance:

The corrosion resistance of Gr23 titanium wire is outstanding, surpassing that of many other medical-grade materials. The stable oxide layer that forms on its surface provides protection against various corrosive environments, including bodily fluids. This property is crucial for long-term implants, as it minimizes the risk of material degradation and the release of potentially harmful metal ions.

While high-grade stainless steels offer good corrosion resistance, they are generally not as resistant as titanium alloys, especially in chloride-rich environments like the human body. Cobalt-chromium alloys also provide good corrosion resistance but may still be susceptible to certain types of corrosion over extended periods.

- Osseointegration:

For orthopedic and dental implants, the ability of the material to integrate with bone tissue (osseointegration) is crucial. Gr23 titanium wire performs exceptionally well in this regard. The surface of titanium implants can be treated or modified to enhance bone cell adhesion and growth, promoting strong and lasting integration with surrounding bone tissue.

Stainless steel and cobalt-chromium alloys, while capable of osseointegration, generally do not perform as well as titanium alloys in this aspect. This is one reason why titanium alloys, including Gr23, are often preferred for dental implants and certain orthopedic applications.

- Imaging Compatibility:

In medical applications, compatibility with imaging techniques is an important consideration. Gr23 titanium wire is non-magnetic and causes minimal artifacts in MRI and CT scans. This property is advantageous for post-operative monitoring and diagnosis.

Stainless steel, particularly ferromagnetic grades, can cause significant artifacts in MRI scans and may pose safety risks in MRI environments. Cobalt-chromium alloys, while less magnetic than some stainless steels, may still cause more imaging artifacts than titanium alloys.

- Cost and Manufacturability:

While Gr23 titanium wire offers numerous advantages, it's worth noting that it is generally more expensive than stainless steel and some other medical-grade materials. The manufacturing processes for titanium alloys can also be more complex and costly. However, the long-term benefits in terms of performance and patient outcomes often justify the higher initial costs.

What are the potential risks associated with using Gr23 Titanium Wire in medical implants?

While Gr23 titanium wire is generally considered safe and is widely used in medical implants, it's important to acknowledge that no material is entirely without risk. Understanding the potential risks associated with using Gr23 titanium wire in medical implants is crucial for healthcare professionals, manufacturers, and patients. Here are some of the potential risks and considerations:

1. Allergic Reactions:

Although titanium allergy is rare, it is not impossible. Some individuals may develop a hypersensitivity to titanium or the alloying elements in Gr23 titanium wire (aluminum and vanadium). Symptoms of a titanium allergy can include skin rashes, inflammation, pain, or in severe cases, implant failure. However, it's important to note that titanium allergies are much less common than allergies to other metals used in implants, such as nickel in stainless steel.

2. Metal Ion Release:

Over time, even highly corrosion-resistant materials like Gr23 titanium wire can release small amounts of metal ions into the surrounding tissues. While the amounts are typically minimal and not considered harmful for most patients, there are concerns about the long-term effects of metal ion accumulation in the body. The release of aluminum and vanadium ions, in particular, has been a subject of study, as these elements can potentially have neurotoxic effects at high concentrations.

3. Stress Shielding:

In orthopedic implants, the high strength and stiffness of Gr23 titanium wire can sometimes lead to a phenomenon known as stress shielding. This occurs when the implant bears more of the load than the surrounding bone, potentially leading to bone resorption and weakening over time. While titanium alloys generally have a lower elastic modulus compared to other implant materials like stainless steel or cobalt-chromium alloys, stress shielding can still occur and may affect the long-term stability of the implant.

4. Wear and Particle Generation:

In applications involving articulating surfaces, such as joint replacements, Gr23 titanium wire may not be the ideal choice due to its relatively poor wear resistance compared to materials like cobalt-chromium alloys. Wear can lead to the generation of titanium particles, which may cause local inflammation and potentially contribute to implant loosening over time. This is why titanium alloys are often used in combination with other materials in joint replacement components.

5. Fatigue Failure:

While Gr23 titanium wire has excellent fatigue resistance, implants are still subject to cyclic loading that can potentially lead to fatigue failure over extended periods. This risk is particularly relevant in high-stress applications like spinal implants or load-bearing joint replacements. Proper design, manufacturing, and quality control are crucial to minimize this risk.

It's important to emphasize that while these risks exist, they are generally considered to be low for most patients. The benefits of using Gr23 titanium wire in medical implants often far outweigh the potential risks. The material's excellent biocompatibility, corrosion resistance, and mechanical properties make it a valuable option in many medical applications.

To mitigate these risks, several strategies are employed:

- Rigorous testing and quality control during manufacturing

- Careful patient screening for potential metal allergies

- Ongoing research into surface modifications and coatings to enhance performance

- Development of new alloy compositions to address specific concerns

- Continuous monitoring and long-term studies of patients with titanium implants

Healthcare professionals carefully weigh the benefits and potential risks when choosing materials for medical implants, considering factors such as the specific application, patient history, and individual needs. As with any medical procedure or device, informed consent and discussion of potential risks with patients are crucial aspects of using Gr23 titanium wire in medical implants.

In conclusion, while Gr23 titanium wire is generally considered safe for use in medical implants, it's not without potential risks. Ongoing research, careful material selection, and proper medical oversight are essential to ensure the continued safe and effective use of this material in medical applications.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

2. Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the mechanical behavior of biomedical materials, 1(1), 30-42.

3. Chen, Q., & Thouas, G. A. (2015). Metallic implant biomaterials. Materials Science and Engineering: R: Reports, 87, 1-57.

4. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants–a review. Progress in materials science, 54(3), 397-425.

5. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

6. Sidambe, A. T. (2014). Biocompatibility of advanced manufactured titanium implants—A review. Materials, 7(12), 8168-8188.

7. Steinemann, S. G. (1998). Titanium—the material of choice?. Periodontology 2000, 17(1), 7-21.

8. Hanawa, T. (2019). Titanium–tissue interface reaction and its control with surface treatment. Frontiers in bioengineering and biotechnology, 7, 170.

9. Wang, K. (1996). The use of titanium for medical applications in the USA. Materials Science and Engineering: A, 213(1-2), 134-137.

10. Oldani, C., & Dominguez, A. (2012). Titanium as a biomaterial for implants. In Recent advances in arthroplasty. IntechOpen.