- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is Titanium Alloy Stronger Than Titanium?

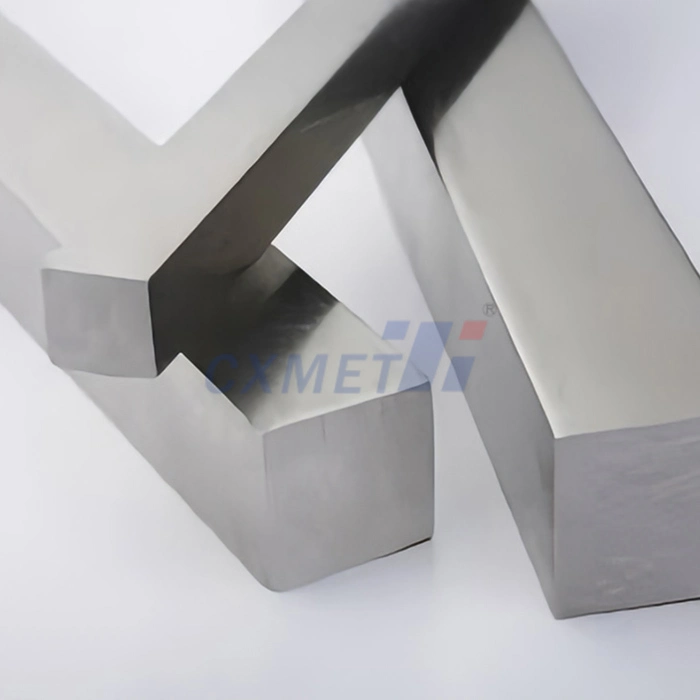

Titanium and its alloys have revolutionized various industries due to their exceptional properties. When comparing titanium alloys to pure titanium, a common question arises: Is titanium alloy stronger than titanium? The answer is generally yes. Titanium alloys are engineered to enhance the already impressive properties of pure titanium, often resulting in superior strength, durability, and performance in specific applications. This blog post will explore the differences between titanium alloys and pure titanium, with a focus on Titanium 0.8Ni-0.3Mo Grade 12 Sheet, a popular alloy known for its excellent corrosion resistance and strength.

What are the key differences between titanium and titanium alloys?

Titanium, in its pure form, is a remarkable metal known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility. However, pure titanium has limitations in certain applications where higher strength or specific properties are required. This is where titanium alloys come into play.

Titanium alloys are created by combining pure titanium with other elements such as aluminum, vanadium, nickel, and molybdenum. These additional elements alter the crystalline structure of titanium, resulting in enhanced mechanical properties. The key differences between titanium and titanium alloys include:

1. Strength: Titanium alloys generally exhibit higher tensile and yield strengths compared to pure titanium. This increased strength allows for the use of titanium alloys in more demanding applications, such as aerospace components and high-performance automotive parts.

2. Hardness: Alloying elements can significantly increase the hardness of titanium, making it more resistant to wear and abrasion. This property is particularly beneficial in applications where surface durability is crucial.

3. Heat resistance: Some titanium alloys demonstrate improved heat resistance compared to pure titanium, making them suitable for high-temperature applications in jet engines and industrial processes.

4. Corrosion resistance: While pure titanium already possesses excellent corrosion resistance, certain alloys can further enhance this property, especially in specific environments. For example, Titanium Grade 12, which contains nickel and molybdenum, offers superior resistance to reducing acids and chloride stress corrosion cracking.

5. Formability: Depending on the alloying elements and heat treatment, some titanium alloys can exhibit improved formability compared to pure titanium, allowing for easier manufacturing and shaping of complex parts.

6. Cost: It's worth noting that while titanium alloys offer superior properties, they are generally more expensive than pure titanium due to the additional alloying elements and more complex production processes.

Understanding these differences is crucial when selecting the appropriate material for a specific application. Engineers and designers must carefully consider the required properties and environmental conditions to determine whether pure titanium or a titanium alloy is the best choice for their project.

How does Titanium 0.8Ni-0.3Mo Grade 12 Sheet compare to other titanium grades?

Titanium 0.8Ni-0.3Mo Grade 12 Sheet, also known as Ti Grade 12 or UNS R53400, is a popular titanium alloy that offers a unique combination of properties. To understand how it compares to other titanium grades, let's examine its composition, characteristics, and typical applications.

Composition:

Titanium Grade 12 contains approximately 0.8% nickel and 0.3% molybdenum, along with trace amounts of other elements such as carbon, iron, oxygen, and nitrogen. The addition of nickel and molybdenum imparts specific properties that set it apart from other titanium grades.

Key characteristics:

1. Corrosion resistance: Grade 12 exhibits exceptional corrosion resistance, particularly in reducing acid environments and against chloride stress corrosion cracking. This makes it superior to many other titanium grades in certain chemical processing applications.

2. Strength: While not as strong as some alpha-beta titanium alloys (e.g., Ti-6Al-4V), Grade 12 offers higher strength than commercially pure titanium grades like Grade 1 or Grade 2.

3. Weldability: Grade 12 maintains good weldability, allowing for easier fabrication and joining of components compared to some higher-strength titanium alloys.

4. Formability: This alloy demonstrates good formability, making it suitable for manufacturing complex shapes and components.

5. Heat resistance: Grade 12 offers improved elevated temperature performance compared to commercially pure titanium grades, though it's not as heat-resistant as some specialized high-temperature titanium alloys.

Comparison to other grades:

- Versus Commercially Pure (CP) Titanium (Grades 1-4): Grade 12 offers higher strength and improved corrosion resistance, particularly in reducing environments. However, CP titanium grades may be more cost-effective for less demanding applications.

- Versus Ti-6Al-4V (Grade 5): While Grade 5 is stronger and more widely used in aerospace applications, Grade 12 excels in corrosion resistance, especially in chemical processing environments.

- Versus other corrosion-resistant grades (e.g., Grade 7, Grade 11): Grade 12 offers a balance between corrosion resistance and strength. It may be preferred in applications where the superior strength of Grade 12 is beneficial, and the extreme corrosion resistance of palladium-containing grades (like Grade 7) is not necessary.

Applications:

Titanium Grade 12 is commonly used in:

- Chemical processing equipment

- Heat exchangers

- Offshore oil and gas components

- Desalination plants

- Marine applications

- Hydrometallurgical extraction processes

When selecting between Titanium 0.8Ni-0.3Mo Grade 12 Sheet and other titanium grades, engineers must consider factors such as specific corrosion resistance requirements, strength needs, operating temperatures, and cost constraints. Grade 12's unique properties make it an excellent choice for applications that demand a balance between corrosion resistance, strength, and formability.

What are the advantages of using Titanium 0.8Ni-0.3Mo Grade 12 Sheet in industrial applications?

Titanium 0.8Ni-0.3Mo Grade 12 Sheet offers numerous advantages in industrial applications, making it a preferred choice in various sectors. Let's explore the key benefits of using this alloy and how it contributes to improved performance and longevity in industrial settings.

1. Superior Corrosion Resistance:

One of the most significant advantages of Titanium Grade 12 is its exceptional corrosion resistance. The addition of nickel and molybdenum enhances its ability to withstand corrosive environments, particularly:

- Reducing acids: Grade 12 performs exceptionally well in sulfuric acid, hydrochloric acid, and other reducing acid environments.

- Chloride stress corrosion cracking: This alloy exhibits excellent resistance to chloride-induced stress corrosion cracking, making it suitable for marine and chemical processing applications.

- Crevice corrosion: Grade 12 demonstrates improved resistance to crevice corrosion compared to commercially pure titanium grades.

This superior corrosion resistance translates to:

- Extended equipment lifespan

- Reduced maintenance costs

- Improved safety in corrosive environments

- Enhanced process reliability in chemical plants and offshore facilities

2. Mechanical Strength:

While not as strong as some alpha-beta titanium alloys, Grade 12 offers improved strength compared to commercially pure titanium grades. This enhanced strength provides:

- Increased load-bearing capacity

- Improved resistance to mechanical wear and fatigue

- Ability to use thinner gauge materials without compromising structural integrity

- Enhanced performance in high-pressure applications

3. Excellent Fabricability:

Titanium Grade 12 maintains good fabrication characteristics, including:

- Weldability: It can be readily welded using various techniques, facilitating easier manufacture and assembly of complex components.

- Formability: The alloy exhibits good cold and hot formability, allowing for the creation of intricate shapes and designs.

- Machinability: While not as easily machined as some other metals, Grade 12 can be machined using standard techniques with proper tooling and cooling.

These fabrication properties result in:

- Greater design flexibility

- Reduced manufacturing costs

- Ability to create complex, custom components for specific industrial applications

4. Temperature Performance:

Grade 12 offers improved elevated temperature performance compared to commercially pure titanium grades. This characteristic is beneficial in:

- Heat exchanger applications

- Process equipment operating at moderately high temperatures

- Components subjected to thermal cycling

5. Lightweight Construction:

Like other titanium alloys, Grade 12 boasts a high strength-to-weight ratio. This property is advantageous in:

- Offshore and marine applications where weight reduction is crucial

- Portable or mobile equipment design

- Reducing overall structural loads in large industrial installations

6. Biocompatibility:

Although not as commonly used in medical applications as some other titanium grades, Grade 12 maintains good biocompatibility. This property can be beneficial in:

- Pharmaceutical processing equipment

- Food processing machinery

- Applications where potential material contact with biological substances is a concern

7. Cost-Effectiveness in Specific Applications:

While titanium alloys are generally more expensive than many other metals, the use of Grade 12 can be cost-effective in the long run due to:

- Reduced need for replacements and maintenance

- Improved process efficiency and uptime

- Potential for thinner gauge materials due to higher strength

- Elimination of costly protective coatings or linings in corrosive environments

8. Versatility:

The combination of corrosion resistance, strength, and fabricability makes Grade 12 a versatile alloy suitable for a wide range of industrial applications, including:

- Chemical processing equipment

- Desalination plants

- Offshore oil and gas components

- Pulp and paper industry equipment

- Hydrometallurgical extraction processes

In conclusion, Titanium 0.8Ni-0.3Mo Grade 12 Sheet offers a unique set of advantages that make it an excellent choice for many industrial applications. Its superior corrosion resistance, combined with good mechanical properties and fabricability, allows for the design and manufacture of durable, efficient, and long-lasting components. While the initial cost may be higher than some alternative materials, the long-term benefits in terms of performance, maintenance reduction, and extended lifespan often justify the investment in this high-performance alloy.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM International. (2021). ASTM B265 - Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate.

2. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

3. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

4. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

5. Schutz, R. W., & Thomas, D. E. (1987). Corrosion of Titanium and Titanium Alloys. ASM Handbook, Volume 13: Corrosion, 669-706.

6. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium Alloys for Aerospace Applications. Advanced Engineering Materials, 5(6), 419-427.

7. Titanium Information Group. (2022). Titanium Alloys - Physical Properties. Retrieved from [website URL]

8. Inagaki, I., Takechi, T., Shirai, Y., & Ariyasu, N. (2014). Application and Features of Titanium for the Aerospace Industry. Nippon Steel & Sumitomo Metal Technical Report No. 106.

9. Revie, R. W., & Uhlig, H. H. (2008). Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering (4th ed.). John Wiley & Sons.

10. Gurrappa, I. (2003). Characterization of titanium alloy Ti-6Al-4V for chemical, marine and industrial applications. Materials Characterization, 51(2-3), 131-139.