- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is Titanium Grade 2 Round Bar Waterproof?

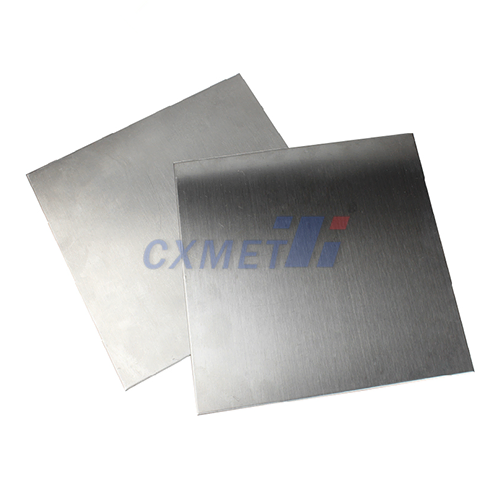

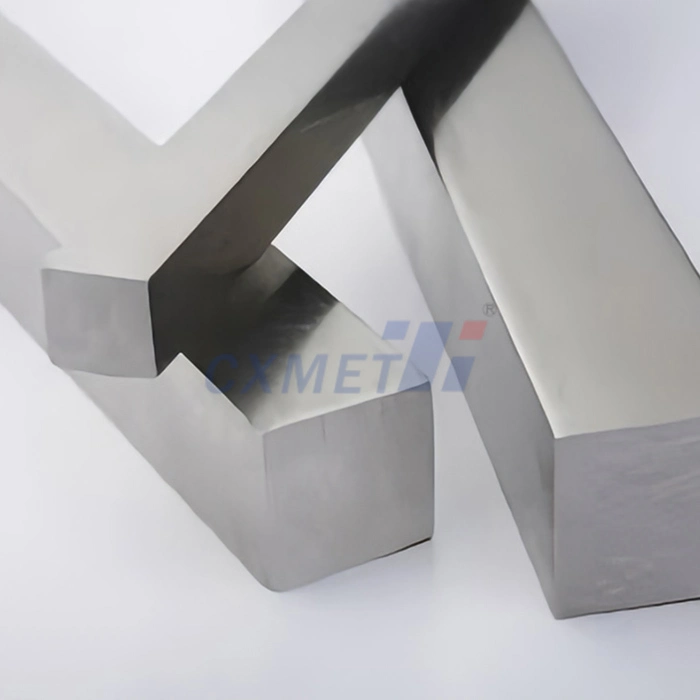

Titanium Grade 2 Round Bar is a popular material known for its excellent corrosion resistance and strength-to-weight ratio. When it comes to waterproofing, Titanium Grade 2 Round Bar exhibits exceptional performance. While not technically "waterproof" in the strictest sense, it is highly resistant to water and corrosion, making it an ideal choice for various applications in marine environments and other water-related industries. This blog post will explore the properties of Titanium Grade 2 Round Bar and its relationship with water resistance.

What are the properties of Titanium Grade 2 Round Bar?

Titanium Grade 2 Round Bar, also known as commercially pure titanium, is a versatile material with a unique combination of properties that make it suitable for a wide range of applications. Some of its key properties include:

1. Excellent corrosion resistance: Titanium Grade 2 has outstanding resistance to corrosion in various environments, including saltwater, acidic solutions, and industrial chemicals. This property is attributed to the formation of a thin, stable oxide layer on the surface of the metal when exposed to air or water.

2. High strength-to-weight ratio: Despite being relatively lightweight, Titanium Grade 2 offers impressive strength, making it an ideal choice for applications where weight reduction is crucial without compromising structural integrity.

3. Low thermal expansion: Titanium Grade 2 has a low coefficient of thermal expansion, which means it maintains its dimensional stability across a wide range of temperatures.

4. Biocompatibility: This material is non-toxic and compatible with human tissue, making it suitable for medical implants and devices.

5. Weldability: Titanium Grade 2 can be easily welded using various techniques, including TIG (Tungsten Inert Gas) welding and laser welding.

6. Formability: It can be formed and shaped using standard metalworking techniques, allowing for the creation of complex shapes and components.

7. Non-magnetic properties: Titanium Grade 2 is non-magnetic, making it suitable for applications where magnetic interference needs to be minimized.

8. Wide temperature range: This material maintains its mechanical properties over a broad range of temperatures, from cryogenic to moderately elevated temperatures.

These properties make Titanium Grade 2 Round Bar an excellent choice for various industries, including aerospace, marine, chemical processing, and medical fields. Its combination of corrosion resistance, strength, and lightweight nature makes it particularly well-suited for applications where exposure to water and harsh environments is a concern.

How does Titanium Grade 2 Round Bar compare to other materials in terms of corrosion resistance?

When it comes to corrosion resistance, Titanium Grade 2 Round Bar stands out as one of the top performers among engineering materials. To understand its superiority, let's compare it to other commonly used materials:

1. Stainless Steel: While stainless steel is known for its corrosion resistance, it can still be susceptible to pitting and crevice corrosion in certain environments, especially those containing chlorides. Titanium Grade 2, on the other hand, offers superior resistance to these types of corrosion, making it a better choice for marine and chemical processing applications.

2. Aluminum: Although aluminum forms a protective oxide layer similar to titanium, it is generally less corrosion-resistant in harsh environments. Titanium Grade 2 outperforms aluminum in saltwater and many chemical environments.

3. Copper alloys: While some copper alloys offer good corrosion resistance, they can be prone to dezincification and stress corrosion cracking. Titanium Grade 2 is not susceptible to these issues and provides more consistent performance across various environments.

4. Carbon steel: Carbon steel is highly susceptible to corrosion in many environments and requires protective coatings or treatments. Titanium Grade 2 offers inherent corrosion resistance without the need for additional protection.

5. Nickel alloys: Some nickel alloys, such as Inconel and Hastelloy, offer excellent corrosion resistance comparable to Titanium Grade 2. However, titanium is generally lighter and more cost-effective for many applications.

The superior corrosion resistance of Titanium Grade 2 Round Bar is primarily due to its ability to form a stable, self-healing oxide layer on its surface. This layer, composed mainly of titanium dioxide (TiO2), forms spontaneously when the metal is exposed to air or water. The oxide layer is extremely thin (typically just a few nanometers thick) but provides excellent protection against corrosive attacks.

Furthermore, if the oxide layer is damaged or scratched, it rapidly reforms, maintaining the material's corrosion resistance. This self-healing property is particularly advantageous in dynamic environments where mechanical wear or abrasion may occur.

In seawater applications, Titanium Grade 2 Round Bar exhibits exceptional performance. It is virtually immune to corrosion in seawater at temperatures up to 260°C (500°F), making it an ideal choice for marine equipment, desalination plants, and offshore structures. Its resistance to chloride-induced stress corrosion cracking, which is a common issue with many stainless steels in marine environments, further enhances its suitability for these applications.

In chemical processing industries, Titanium Grade 2 Round Bar's corrosion resistance is valuable in handling a wide range of chemicals, including organic compounds, inorganic salts, and many acids. Its ability to withstand oxidizing acids, such as nitric acid, sets it apart from many other materials.

It's worth noting that while Titanium Grade 2 offers excellent general corrosion resistance, there are specific environments where it may not be the best choice. For instance, it can be susceptible to attack by reducing acids, such as hydrochloric acid or sulfuric acid, especially at elevated temperatures. In such cases, higher-grade titanium alloys or other specialized materials may be more suitable.

What are the applications of Titanium Grade 2 Round Bar in water-related industries?

Titanium Grade 2 Round Bar finds extensive use in water-related industries due to its exceptional corrosion resistance and other favorable properties. Here are some key applications:

1. Marine and offshore industries:

- Propeller shafts and other marine propulsion components

- Pumps and valves for seawater handling systems

- Heat exchangers in desalination plants

- Offshore oil and gas platform components

- Subsea equipment and structures

2. Water treatment and desalination:

- Reverse osmosis membranes support structures

- Piping systems for high-salinity water

- Filtration equipment

- Pump components and impellers

3. Chemical processing:

- Reactors and vessels for processes involving aqueous solutions

- Piping systems for corrosive liquids

- Heat exchangers for aggressive environments

4. Hydroelectric power generation:

- Turbine components

- Valve stems and gates

- Pipe fittings and flanges

5. Pulp and paper industry:

- Digesters and bleaching equipment

- Pumps and valves for handling corrosive pulp and paper chemicals

6. Food and beverage processing:

- Storage tanks for high-purity water

- Piping systems in breweries and distilleries

- Heat exchangers in dairy processing

7. Aquaculture:

- Fish farm cages and netting supports

- Water circulation and aeration systems

8. Oceanographic research:

- Instrument housings and sensor components

- Submersible vehicle parts

9. Swimming pool equipment:

- Heat exchanger tubes

- Pump components

- Filtration system parts

10. Geothermal energy:

- Well casings

- Heat exchanger tubes

- Piping for geothermal fluids

In these applications, Titanium Grade 2 Round Bar offers several advantages:

Longevity: Its excellent corrosion resistance translates to extended service life, reducing maintenance and replacement costs.

Safety: The material's reliability in harsh environments enhances overall system safety, particularly important in offshore and marine applications.

Energy efficiency: The low friction coefficient of titanium's oxide layer can improve fluid flow efficiency in piping systems.

Weight reduction: In marine and offshore applications, the use of lightweight titanium components can contribute to overall weight savings, improving fuel efficiency and structural design.

Biofilm resistance: Titanium's surface properties make it less prone to biofilm formation, which is beneficial in water treatment and food processing applications.

Thermal efficiency: In heat exchanger applications, titanium's excellent thermal conductivity coupled with its thin-walled design capabilities can lead to improved heat transfer efficiency.

While the initial cost of Titanium Grade 2 Round Bar may be higher than some alternative materials, its long-term benefits often result in a lower total cost of ownership for many water-related applications. The material's durability, minimal maintenance requirements, and excellent performance in challenging environments make it a cost-effective choice for critical components in water-related industries.

In conclusion, Titanium Grade 2 Round Bar's exceptional corrosion resistance, particularly in water-related environments, makes it an invaluable material across various industries. While not technically "waterproof" in the strictest sense, its ability to form a protective oxide layer provides outstanding protection against water and corrosive elements. This property, combined with its strength, lightweight nature, and other beneficial characteristics, positions Titanium Grade 2 Round Bar as a top choice for applications where exposure to water and harsh environments is a primary concern. As industries continue to demand materials with superior performance and longevity, Titanium Grade 2 Round Bar is likely to play an increasingly important role in water-related applications and beyond.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM International. (2021). ASTM B348 - Standard Specification for Titanium and Titanium Alloy Bars and Billets.

2. Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

3. Schutz, R. W., & Thomas, D. E. (1987). Corrosion of titanium and titanium alloys. ASM Handbook, 13, 669-706.

4. Titanium Industries. (2022). Titanium Grade 2 Properties and Applications. Retrieved from https://www.titanium.com/

5. NACE International. (2018). Corrosion in the Water and Wastewater Industry.

6. Davis, J. R. (Ed.). (2001). Alloying: Understanding the Basics. ASM International.

7. Lütjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

8. Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

9. Revie, R. W., & Uhlig, H. H. (2008). Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering. John Wiley & Sons.

10. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

2.webp)