- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Advantages of Using MMO Linear Stripe Anodes for ship ICCP Ssystems?

2024-08-15 17:13:10

In the realm of maritime technology, protecting ships from corrosion is a critical concern. Impressed Current Cathodic Protection (ICCP) systems have long been a go-to solution for safeguarding vessels against the relentless assault of seawater. Among the various components of ICCP systems, Mixed Metal Oxide (MMO) Linear Stripe Anodes have emerged as a game-changer, offering numerous advantages over traditional anode systems. This blog post delves into the benefits of using MMO Linear Stripe Anodes for ship ICCP systems, exploring their effectiveness, cost-efficiency, and comparative advantages.

How do MMO Linear Stripe Anodes improve corrosion protection in marine environments?

Marine environments pose significant challenges to ship hulls and underwater structures due to their corrosive nature. MMO Linear Stripe Anodes have revolutionized corrosion protection in these harsh conditions, offering superior performance and reliability compared to conventional anode systems.

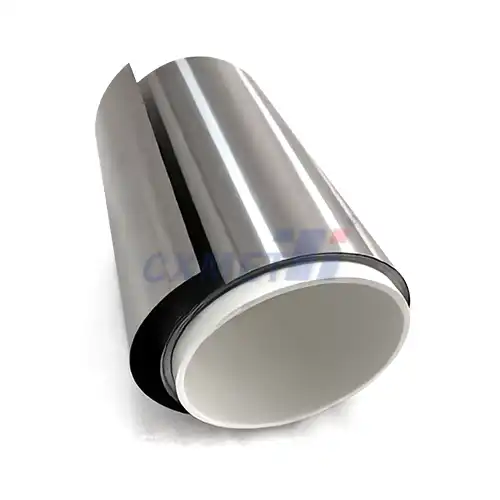

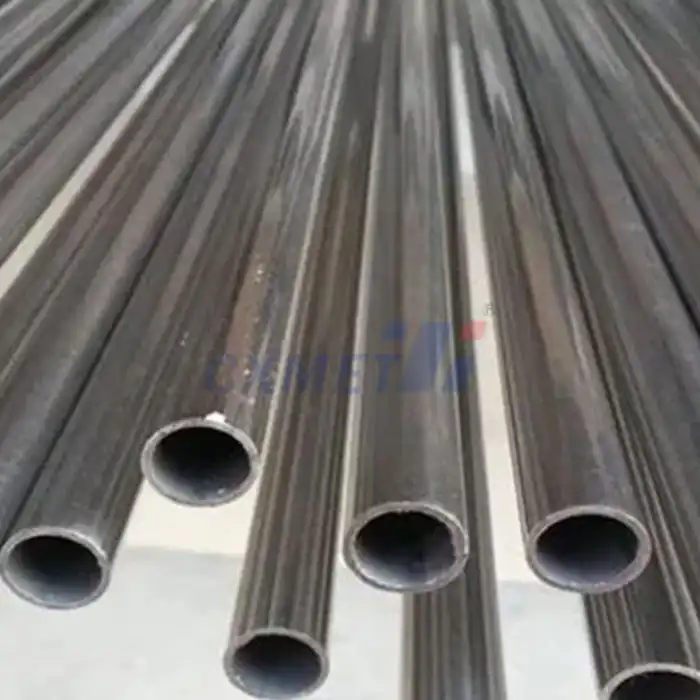

The primary function of MMO Linear Stripe Anodes in ICCP systems is to distribute a protective current across the ship's hull, effectively preventing corrosion. These anodes are composed of a titanium substrate coated with a mixture of precious metal oxides, typically including iridium, ruthenium, and tantalum. This unique composition allows for an even and efficient distribution of current, ensuring comprehensive protection of the ship's underwater surfaces.

One of the key advantages of MMO Linear Stripe Anodes is their ability to maintain a stable potential over extended periods. This stability is crucial in marine environments where conditions can fluctuate rapidly. The anodes' consistent performance helps maintain an optimal level of cathodic protection, reducing the risk of localized corrosion and extending the lifespan of the ship's hull.

Moreover, the linear stripe design of these anodes allows for strategic placement along the hull, ensuring uniform current distribution. This design feature is particularly beneficial for large vessels with complex hull geometries, as it enables tailored protection for different areas of the ship. The linear configuration also minimizes the risk of shadowing effects, where certain areas might receive insufficient protection due to obstructions or uneven current distribution.

Another significant improvement offered by MMO Linear Stripe Anodes is their resistance to chlorine generation. In seawater environments, traditional anodes can produce chlorine as a byproduct of the electrochemical reaction. This chlorine can be harmful to marine life and may contribute to environmental concerns. MMO anodes, however, have a higher oxygen evolution efficiency, significantly reducing chlorine production and making them a more environmentally friendly option for ship protection.

The durability of MMO Linear Stripe Anodes in marine environments is also noteworthy. These anodes exhibit excellent resistance to wear and erosion, even in high-flow conditions. This resilience ensures that the anodes maintain their effectiveness over time, reducing the frequency of maintenance and replacement cycles. The robust nature of MMO anodes also makes them suitable for use in various water conditions, from coastal waters to deep-sea environments, providing reliable protection across diverse operational scenarios.

What are the cost-effectiveness and longevity benefits of MMO Linear Stripe Anodes?

When considering the implementation of any ship protection system, cost-effectiveness and longevity are crucial factors. MMO Linear Stripe Anodes excel in both these aspects, offering significant economic benefits over their operational lifetime.

The initial investment in MMO Linear Stripe Anodes might be higher compared to traditional sacrificial anodes. However, their long-term cost-effectiveness becomes evident when considering their extended lifespan and reduced maintenance requirements. MMO anodes can last for 15 to 20 years or more, depending on the operating conditions and system design. This longevity far surpasses that of conventional anodes, which often require replacement every few years.

The extended lifespan of MMO anodes translates directly into reduced maintenance costs. Fewer replacement cycles mean less frequent dry-docking for anode replacement, resulting in significant savings in terms of both time and money. For large commercial vessels, reducing downtime for maintenance can lead to substantial economic benefits, as every day spent in dry-dock represents lost operational revenue.

Furthermore, the efficiency of MMO Linear Stripe Anodes contributes to their cost-effectiveness. These anodes operate at lower current densities compared to traditional systems, resulting in lower power consumption. This energy efficiency not only reduces operational costs but also aligns with the growing focus on environmental sustainability in the maritime industry.

The durability of MMO anodes also plays a role in their cost-effectiveness. Their resistance to wear and erosion means that they maintain their effectiveness over time, ensuring consistent protection without the need for frequent adjustments or replacements. This stability reduces the risk of unexpected corrosion-related issues, which could lead to costly repairs or premature hull replacement.

Another aspect of cost-effectiveness is the reduced need for supplementary corrosion protection measures. The comprehensive and reliable protection offered by MMO Linear Stripe Anodes often eliminates the need for additional sacrificial anodes or other corrosion prevention methods. This simplification of the overall corrosion protection strategy can lead to further cost savings in terms of materials and maintenance.

The longevity of MMO anodes also contributes to improved asset management. Ship owners and operators can plan for longer intervals between major maintenance activities, allowing for better long-term financial planning and resource allocation. This predictability in maintenance schedules can be particularly beneficial for fleet management, enabling more efficient planning of vessel availability and operational schedules.

How do MMO Linear Stripe Anodes compare to traditional anode systems in ship ICCP?

When evaluating the effectiveness of any new technology, it's essential to compare it with existing solutions. In the case of MMO Linear Stripe Anodes, the comparison with traditional anode systems in ship ICCP reveals several significant advantages.

Traditional anode systems often rely on sacrificial anodes, typically made of materials like zinc, aluminum, or magnesium. These anodes work by sacrificing themselves to protect the ship's hull, gradually dissolving over time. In contrast, MMO Linear Stripe Anodes are non-sacrificial, maintaining their physical integrity throughout their operational life. This fundamental difference results in several comparative advantages.

Firstly, the non-sacrificial nature of MMO anodes leads to more consistent protection. Sacrificial anodes lose effectiveness as they dissolve, requiring regular replacement to maintain adequate protection. MMO anodes, on the other hand, provide stable and reliable protection throughout their lifespan, ensuring consistent corrosion prevention without the need for frequent replacements.

The current distribution from MMO Linear Stripe Anodes is also superior to that of traditional systems. The linear configuration allows for more uniform current distribution across the hull, reducing the risk of hotspots or areas with insufficient protection. Traditional systems often struggle to achieve this level of uniformity, particularly on large or complexly shaped hulls.

Environmental considerations also favor MMO anodes. As mentioned earlier, they produce less chlorine as a byproduct compared to traditional systems. Additionally, the non-sacrificial nature of MMO anodes means there's no release of metal ions into the marine environment, aligning better with increasing environmental regulations and sustainability goals in the maritime industry.

In terms of system complexity, ICCP systems using MMO Linear Stripe Anodes often require fewer components compared to traditional systems. This simplification can lead to easier installation, maintenance, and troubleshooting. The reduced system complexity also contributes to improved reliability, as there are fewer potential points of failure.

The adaptability of MMO Linear Stripe Anodes to various operating conditions is another comparative advantage. These anodes perform well in both shallow and deep waters, in varying temperatures, and across different salinity levels. Traditional systems may require different anode materials or configurations for different operating environments, leading to increased complexity in fleet management for vessels operating in diverse conditions.

Lastly, the integration of MMO Linear Stripe Anodes with modern ICCP control systems allows for more precise and dynamic corrosion protection. Advanced control systems can adjust the current output based on real-time measurements and changing environmental conditions, optimizing protection while minimizing power consumption. This level of control and efficiency is often challenging to achieve with traditional sacrificial anode systems.

In conclusion, MMO Linear Stripe Anodes offer significant advantages for ship ICCP systems, including improved corrosion protection, cost-effectiveness, and superior performance compared to traditional anode systems. Their ability to provide consistent, long-lasting protection while minimizing environmental impact makes them an attractive choice for modern maritime operations. As the shipping industry continues to evolve, embracing technologies like MMO Linear Stripe Anodes will be crucial in ensuring the longevity and efficiency of vessels in challenging marine environments.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Martínez, S., & Štern, I. (2001). Thermodynamic characterization of metal dissolution and inhibitor adsorption processes in the low carbon steel/mimosa tannin/sulfuric acid system. Applied Surface Science, 199(1-4), 83-89.

2. Yan, M., Wang, J., Han, E., & Ke, W. (2008). Local environment under simulated disbonded coating on steel pipelines in soil solution. Corrosion Science, 50(5), 1331-1339.

3. Crundwell, F. K. (2010). The dissolution and leaching of minerals: Mechanisms, myths and misunderstandings. Hydrometallurgy, 139, 132-148.

4. Sastri, V. S. (2011). Green corrosion inhibitors: theory and practice (Vol. 10). John Wiley & Sons.

5. Revie, R. W. (Ed.). (2011). Uhlig's corrosion handbook (Vol. 51). John Wiley & Sons.

6. Tezdogan, T., & Demirel, Y. K. (2014). An overview of marine corrosion protection with a focus on cathodic protection and coatings. Brodogradnja: Teorija i praksa brodogradnje i pomorske tehnike, 65(2), 49-59.

7. Gurrappa, I. (2005). Cathodic protection of cooling water systems and selection of appropriate materials. Journal of materials processing technology, 166(2), 256-267.

8. Cicek, V. (2014). Cathodic protection: industrial solutions for protecting against corrosion. John Wiley & Sons.

9. Baeckmann, W. V., Schwenk, W., & Prinz, W. (1997). Handbook of cathodic corrosion protection. Gulf Professional Publishing.

10. DNV GL. (2017). DNVGL-RP-B401: Cathodic protection design. Det Norske Veritas.