- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Advantages of Using Tantalum Discs in Medical Implants?

2024-08-02 17:06:37

In recent years, the field of medical implants has seen significant advancements, with various materials being explored to enhance patient outcomes. Among these, Tantalum has emerged as a promising option, particularly in the form of discs used in various implant applications. Tantalum, a rare, blue-gray metal, has gained attention in the medical community due to its unique properties that make it highly suitable for implant use. This blog post will delve into the advantages of using Tantalum discs in medical implants and explore some of the most common questions surrounding this innovative material.

How does Tantalum compare to other materials used in medical implants?

When it comes to medical implants, the choice of material is crucial for ensuring long-term success and patient comfort. Tantalum has several distinct advantages that set it apart from other commonly used materials such as titanium, stainless steel, and cobalt-chromium alloys.

Firstly, Tantalum boasts exceptional biocompatibility. The human body readily accepts Tantalum implants, with minimal risk of rejection or adverse reactions. This biocompatibility is partly due to Tantalum's ability to form a stable oxide layer on its surface, which helps prevent corrosion and the release of potentially harmful metal ions into the surrounding tissues.

Secondly, Tantalum exhibits remarkable osseointegration properties. When used in orthopedic implants, Tantalum encourages bone ingrowth and attachment, leading to a strong and stable interface between the implant and the patient's natural bone. This characteristic is particularly beneficial in applications such as joint replacements and spinal fusion devices, where a secure bond between the implant and bone is essential for long-term success.

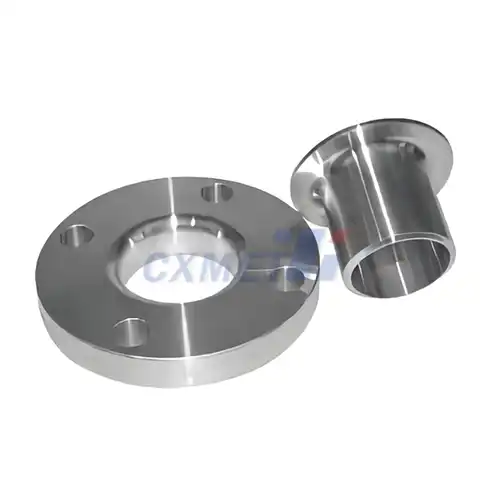

Another significant advantage of Tantalum is its high ductility and malleability. These properties allow for the creation of porous structures that closely mimic the architecture of natural bone. Porous Tantalum implants, often referred to as trabecular metal, provide an ideal environment for bone ingrowth and vascularization. This porous structure not only enhances the implant's integration with the surrounding tissue but also helps distribute stress more evenly, reducing the risk of implant loosening over time.

Tantalum also offers excellent radiographic properties. Unlike some other implant materials, Tantalum is highly visible on X-rays and other imaging modalities. This visibility allows for easier post-operative monitoring and assessment of the implant's position and integration. For surgeons and healthcare providers, this enhanced visibility can be invaluable in ensuring proper placement and tracking the long-term performance of the implant.

Furthermore, Tantalum demonstrates superior wear resistance compared to many other implant materials. This property is particularly important in applications where the implant may be subject to constant movement or friction, such as in joint replacements. The high wear resistance of Tantalum can contribute to increased implant longevity and reduced need for revision surgeries.

Lastly, Tantalum's thermal expansion coefficient is similar to that of bone, which helps minimize stress at the implant-bone interface during temperature fluctuations. This property can contribute to improved long-term stability and reduced risk of implant loosening.

What are the potential risks associated with Tantalum implants?

While Tantalum offers numerous advantages as an implant material, it's important to consider potential risks and limitations associated with its use. Understanding these factors is crucial for healthcare providers and patients alike when considering Tantalum-based implants.

One of the primary concerns with any implant material is the potential for allergic reactions or hypersensitivity. Although Tantalum is generally considered highly biocompatible, there have been rare reports of patients experiencing allergic reactions to the metal. These reactions can manifest as skin irritation, inflammation, or other systemic symptoms. However, it's worth noting that the incidence of such reactions is significantly lower with Tantalum compared to other metals commonly used in implants, such as nickel or cobalt.

Another potential risk associated with Tantalum implants is the possibility of metal ion release. While Tantalum is known for its excellent corrosion resistance, no material is entirely immune to degradation over time. In some cases, small amounts of Tantalum ions may be released into the surrounding tissues or bloodstream. The long-term effects of these metal ions on the human body are still being studied, but current research suggests that the levels of Tantalum ions released from implants are generally well below the threshold for toxicity concerns.

The high density of Tantalum can also present challenges in certain applications. While this property contributes to its excellent radiographic visibility, it can also make Tantalum implants heavier than those made from other materials. In some cases, this increased weight might affect the overall balance and function of the implanted area, particularly in larger joint replacements or spinal implants. Surgeons must carefully consider this factor when selecting the appropriate implant for each patient.

Cost is another potential limitation of Tantalum implants. Due to its rarity and the complex manufacturing processes required to create porous Tantalum structures, implants made from this material are often more expensive than those made from more common materials like titanium or stainless steel. This higher cost can impact healthcare systems and patient access to Tantalum-based implants, particularly in regions with limited healthcare resources.

Additionally, while the porous structure of Tantalum implants offers excellent osseointegration properties, it can also present challenges in the event that implant removal becomes necessary. The strong bond formed between the porous Tantalum and the surrounding bone can make revision surgeries more complex and potentially increase the risk of bone loss or damage during implant removal.

Lastly, as with any medical implant, there is always a risk of infection. While Tantalum itself does not increase the likelihood of infection, the presence of any foreign material in the body can potentially serve as a site for bacterial colonization. Proper surgical techniques, sterilization protocols, and post-operative care are crucial in minimizing this risk, regardless of the implant material used.

Why is Tantalum becoming more popular in orthopedic surgeries?

In recent years, Tantalum has gained significant traction in the field of orthopedic surgery, with an increasing number of surgeons and patients opting for Tantalum-based implants. This growing popularity can be attributed to several factors that highlight the unique advantages of this remarkable metal in orthopedic applications.

One of the primary reasons for Tantalum's rising popularity is its exceptional osseointegration properties. The porous structure of Tantalum implants, often referred to as trabecular metal, closely mimics the architecture of natural bone. This similarity allows for rapid and extensive bone ingrowth, leading to a strong and stable bond between the implant and the patient's own bone tissue. For orthopedic surgeons, this enhanced osseointegration translates to improved implant stability, reduced risk of loosening, and potentially better long-term outcomes for patients.

The high coefficient of friction exhibited by Tantalum is another factor contributing to its popularity in orthopedic surgeries. This property is particularly beneficial in applications such as acetabular cups in hip replacements or tibial components in knee replacements. The increased friction helps ensure initial stability of the implant, reducing the risk of early migration or loosening. This can be especially advantageous in cases where immediate post-operative weight-bearing is desired or in revision surgeries where bone quality may be compromised.

Tantalum's excellent biocompatibility has also played a significant role in its growing adoption in orthopedic procedures. The human body's acceptance of Tantalum implants, coupled with the minimal risk of allergic reactions or adverse tissue responses, makes it an attractive option for patients with sensitivities to other metals commonly used in implants. This biocompatibility can contribute to reduced inflammation, faster healing, and improved patient comfort post-surgery.

The unique radiographic properties of Tantalum have further enhanced its appeal in orthopedic applications. The high atomic number of Tantalum results in excellent visibility on X-rays and other imaging modalities. This enhanced visibility allows surgeons to more accurately assess implant positioning during surgery and monitor integration and potential complications in follow-up examinations. For complex revision surgeries or cases involving significant bone loss, this improved visualization can be invaluable in achieving optimal outcomes.

Another factor driving the increased use of Tantalum in orthopedic surgeries is its versatility. Tantalum can be used in various forms, from solid components to highly porous structures, allowing for customization based on specific surgical needs. This versatility enables the creation of implants that can address a wide range of orthopedic challenges, from primary joint replacements to complex reconstructions in cases of severe bone loss or deformity.

The growing body of clinical evidence supporting the long-term success of Tantalum implants has also contributed to its rising popularity. Numerous studies have demonstrated excellent survival rates and functional outcomes for Tantalum-based implants in various orthopedic applications. This accumulating evidence has given surgeons and patients increased confidence in choosing Tantalum implants, particularly in challenging cases where traditional materials may have limitations.

Lastly, advancements in manufacturing technologies have made it possible to produce Tantalum implants with increasingly sophisticated designs and structures. These innovations have expanded the potential applications of Tantalum in orthopedic surgery, allowing for the creation of implants that can better address specific anatomical and biomechanical requirements. As manufacturing techniques continue to evolve, it's likely that we'll see even more innovative uses of Tantalum in orthopedic implants in the future.

In conclusion, the advantages of using Tantalum discs in medical implants are numerous and significant. From its exceptional biocompatibility and osseointegration properties to its unique radiographic characteristics and versatility, Tantalum has proven to be a valuable material in the field of medical implants, particularly in orthopedic applications. While there are potential risks and limitations to consider, the growing popularity of Tantalum in orthopedic surgeries reflects its ability to address many of the challenges faced in modern implant design and application. As research continues and manufacturing techniques advance, it's likely that we'll see even more innovative uses of Tantalum in medical implants, potentially revolutionizing patient care and outcomes in the years to come.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Levine, B. R., Sporer, S., Poggie, R. A., Della Valle, C. J., & Jacobs, J. J. (2006). Experimental and clinical performance of porous tantalum in orthopedic surgery. Biomaterials, 27(27), 4671-4681.

2. Bobyn, J. D., Stackpool, G. J., Hacking, S. A., Tanzer, M., & Krygier, J. J. (1999). Characteristics of bone ingrowth and interface mechanics of a new porous tantalum biomaterial. Journal of Bone and Joint Surgery, 81(5), 907-914.

3. Findlay, D. M., Welldon, K. J., Atkins, G. J., Howie, D. W., Zannettino, A. C., & Bobyn, D. (2004). The proliferation and phenotypic expression of human osteoblasts on tantalum metal. Biomaterials, 25(12), 2215-2227.

4. Kamath, A. F., Lewallen, D. G., & Hanssen, A. D. (2011). Porous tantalum metaphyseal cones for severe tibial bone loss in revision knee arthroplasty: a five to nine-year follow-up. Journal of Bone and Joint Surgery, 93(5), 478-487.

5. Meneghini, R. M., Ford, K. S., McCollough, C. H., Hanssen, A. D., & Lewallen, D. G. (2010). Bone remodeling around porous metal cementless acetabular components. Journal of Arthroplasty, 25(5), 741-747.

6. Patil, N., Lee, K., & Goodman, S. B. (2009). Porous tantalum in hip and knee reconstructive surgery. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 89(1), 242-251.

7. Oron, A., Agar, G., Oron, U., & Stein, A. (2012). Correlation between rate of bony ingrowth to stainless steel, pure titanium, and titanium alloy implants in vivo and formation of hydroxyapatite on their surfaces in vitro. Journal of Biomedical Materials Research Part A, 100(7), 1652-1660.

8. Balla, V. K., Bodhak, S., Bose, S., & Bandyopadhyay, A. (2010). Porous tantalum structures for bone implants: fabrication, mechanical and in vitro biological properties. Acta Biomaterialia, 6(8), 3349-3359.

9. Wauthle, R., van der Stok, J., Amin Yavari, S., Van Humbeeck, J., Kruth, J. P., Zadpoor, A. A., ... & Schrooten, J. (2015). Additively manufactured porous tantalum implants. Acta Biomaterialia, 14, 217-225.

10. Hanzlik, J. A., & Day, J. S. (2013). Bone ingrowth in well-fixed retrieved porous tantalum implants. Journal of Arthroplasty, 28(6), 922-927.