- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Applications of Tungsten Heavy Alloy?

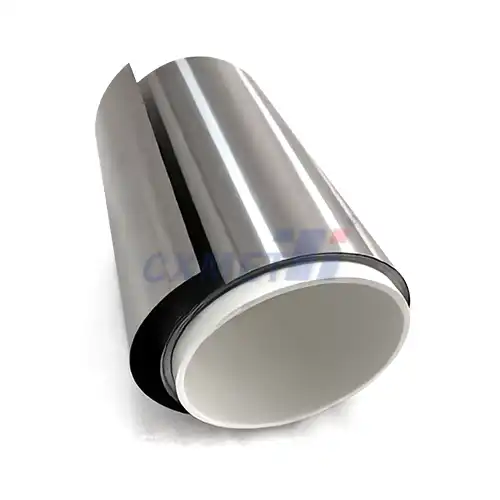

Tungsten heavy alloys (WHAs) are a unique class of materials renowned for their exceptional density, high strength, and resistance to wear and corrosion. These alloys, primarily composed of tungsten and a binder metal like nickel or iron, have found extensive applications across various industries due to their remarkable properties. From aerospace and defense to energy and construction, WHAs play a crucial role in numerous applications, making them an indispensable material in modern engineering.

What is the density of tungsten heavy alloy bars?

Tungsten heavy alloy bars boast an extremely high density, typically ranging from 17 to 18.5 g/cm³, which is nearly twice the density of lead. This exceptional density is attributed to the presence of tungsten, a dense refractory metal with an atomic weight of 183.84 u. The density of WHAs varies depending on the specific composition and manufacturing process, but it is largely determined by the high concentration of tungsten, often exceeding 90% by weight.

The high density of tungsten heavy alloy bars makes them ideal for applications that require significant mass and compact size. One prominent application is in counterweights and balance weights, where their high density enables the creation of smaller and more efficient components. They are also extensively used in radiation shielding applications, such as in medical equipment, nuclear power plants, and particle accelerators, as their density effectively attenuates various forms of radiation.

Moreover, tungsten heavy alloy bars find applications in kinetic energy penetrators, which are used in armor-piercing ammunition for their ability to penetrate thick armor plates. The high density and mass of these bars enable them to maintain their momentum and kinetic energy over long distances, resulting in enhanced penetration capabilities.

How is tungsten heavy alloy bar made?

The manufacturing process of tungsten heavy alloy bars involves several intricate steps to achieve the desired properties and dimensions. The primary raw materials used are tungsten powder, a binder metal (typically nickel or iron), and sometimes small amounts of other alloying elements.

The first step involves blending the tungsten powder with the binder metal and any additional alloying elements in the desired proportions. This mixture is then subjected to a process called liquid phase sintering, where it is compacted and heated to a temperature above the melting point of the binder metal, but below the melting point of tungsten. During this process, the molten binder metal infiltrates the tungsten powder, forming a dense and homogeneous alloy.

After sintering, the alloy undergoes various secondary operations, such as hot isostatic pressing (HIP) or cold isostatic pressing (CIP), to further enhance its density and mechanical properties. These processes apply high pressure to the alloy, eliminating any remaining porosity and increasing its structural integrity.

The alloy is then subjected to various machining and finishing operations, such as turning, milling, grinding, and polishing, to achieve the desired dimensions and surface finish for the tungsten heavy alloy bars. Depending on the application, additional heat treatments or surface coatings may be applied to optimize the properties of the final product.

What are the advantages of using tungsten heavy alloy bars?

Tungsten heavy alloy bars offer numerous advantages that make them highly desirable in various applications. One of their primary advantages is their exceptional density, which enables them to provide significant mass and weight in a compact form factor. This characteristic is particularly valuable in applications where space and weight constraints are critical, such as in aerospace, defense, and sporting goods industries.

Another significant advantage of tungsten heavy alloy bars is their high strength and hardness. These properties are attributed to the presence of tungsten, which is an extremely hard and refractory metal. As a result, WHAs exhibit superior wear resistance, making them suitable for applications involving high mechanical loads, abrasive environments, or extreme temperatures.

Furthermore, tungsten heavy alloy bar bars possess excellent corrosion resistance, particularly in acidic and alkaline environments. This characteristic makes them ideal for use in harsh environments, such as in the chemical industry, oil and gas exploration, and marine applications.

Additionally, WHAs have exceptional radiation shielding properties due to their high density and the presence of tungsten, which has a high atomic number. This makes them suitable for applications involving radiation sources, such as in medical imaging equipment, nuclear facilities, and particle accelerators.

Another advantage of tungsten heavy alloy bars is their non-magnetic properties, which make them suitable for use in applications where magnetic fields need to be avoided or minimized, such as in certain electrical and electronic components.

Overall, the unique combination of properties offered by tungsten heavy alloy bars, including high density, strength, hardness, corrosion resistance, radiation shielding, and non-magnetic behavior, make them invaluable in a wide range of applications across various industries.

Conclusion

Tungsten heavy alloys, with their exceptional density, strength, and resistance to wear and corrosion, have found numerous applications across various industries. From radiation shielding and ballistic protection to counterweights and kinetic energy penetrators, these alloys play a crucial role in numerous applications. As technology continues to advance, the demand for high-performance materials like tungsten heavy alloys is expected to increase, driving further research and innovation in their production and application.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Bose, A., & Meinhardt, J. (2019). Tungsten heavy alloys: Properties and applications. Materials Science and Technology, 35(18), 2133-2149.

2. German, R. M. (2020). Liquid phase sintering of tungsten heavy alloys. International Journal of Refractory Metals and Hard Materials, 91, 105262.

3. Gupta, N. K., & Prasad, R. (2014). Tungsten based materials for aerospace applications. International Journal of Refractory Metals and Hard Materials, 42, 38-46.

4. Lassner, E., & Schubert, W. D. (2012). Tungsten: Properties, chemistry, technology of the element, alloys, and chemical compounds. Springer Science & Business Media.

5. Lee, S., & Sanhueza, J. C. (2019). Tungsten heavy alloys: Properties and applications. In Refractory Metals and Alloys (pp. 121-147). CRC Press.

6. Murty, B. S., & Charit, I. (2022). Tungsten heavy alloys: Processing, properties, and applications. CRC Press.

7. Pak, J., & Sanhueza, J. C. (2018). Tungsten heavy alloys: Processing, properties, and applications. In Refractory Metals and Alloys (pp. 141-167). CRC Press.

8. Rajput, R. K. (2020). A textbook of manufacturing technology: Manufacturing processes. Laxmi Publications.

9. Senkov, O. N., & Senkova, S. V. (2022). Tungsten heavy alloys: From conventional to advanced materials. Materials Science and Engineering: R: Reports, 147, 100667.

10. Wolfram, H. (2021). Tungsten heavy alloys: Processing, properties, and applications. In Advanced Materials and Processing (pp. 209-239). Springer, Cham.