- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

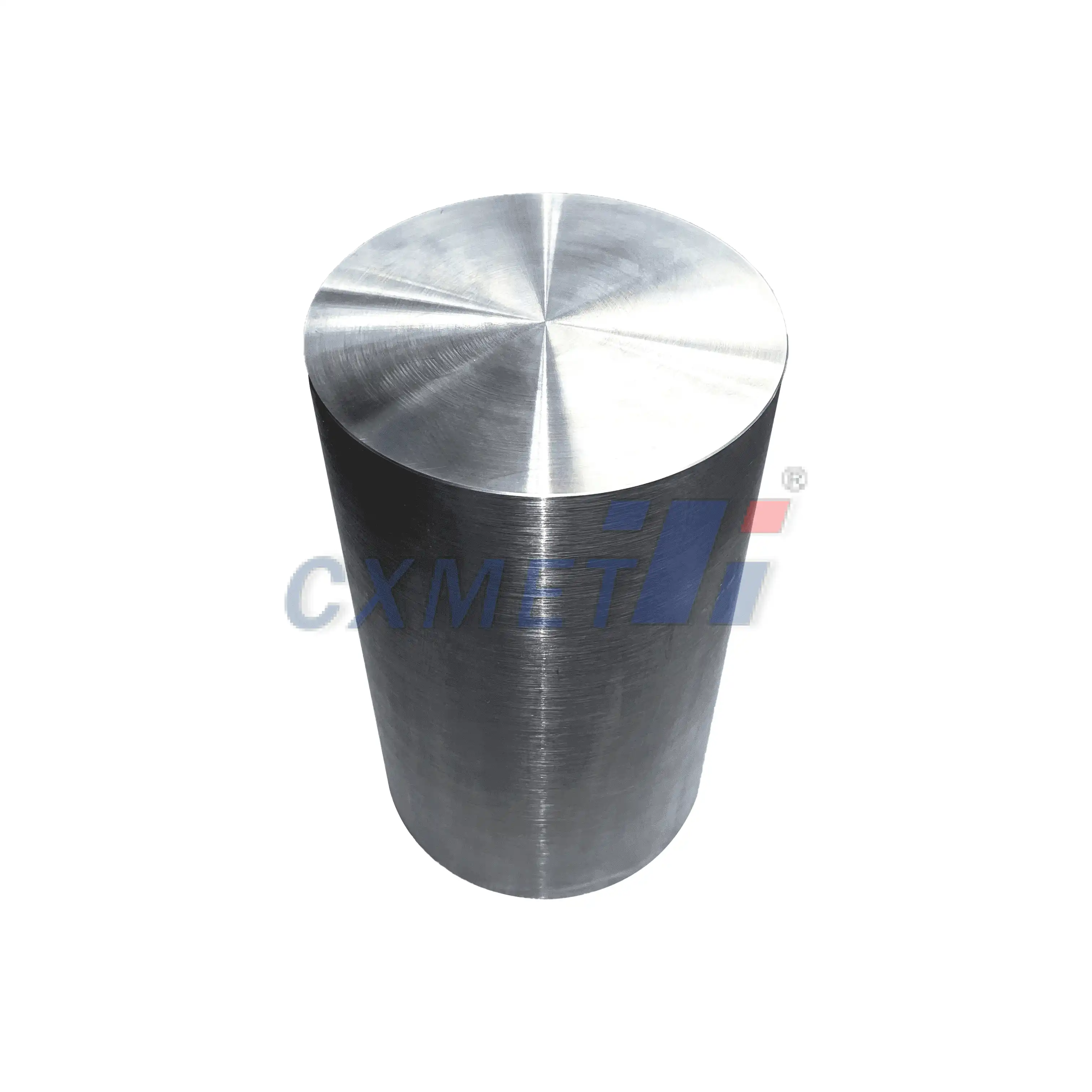

What Are The Properties Of Zr702 Zirconium Rods?

2025-01-06 15:07:48

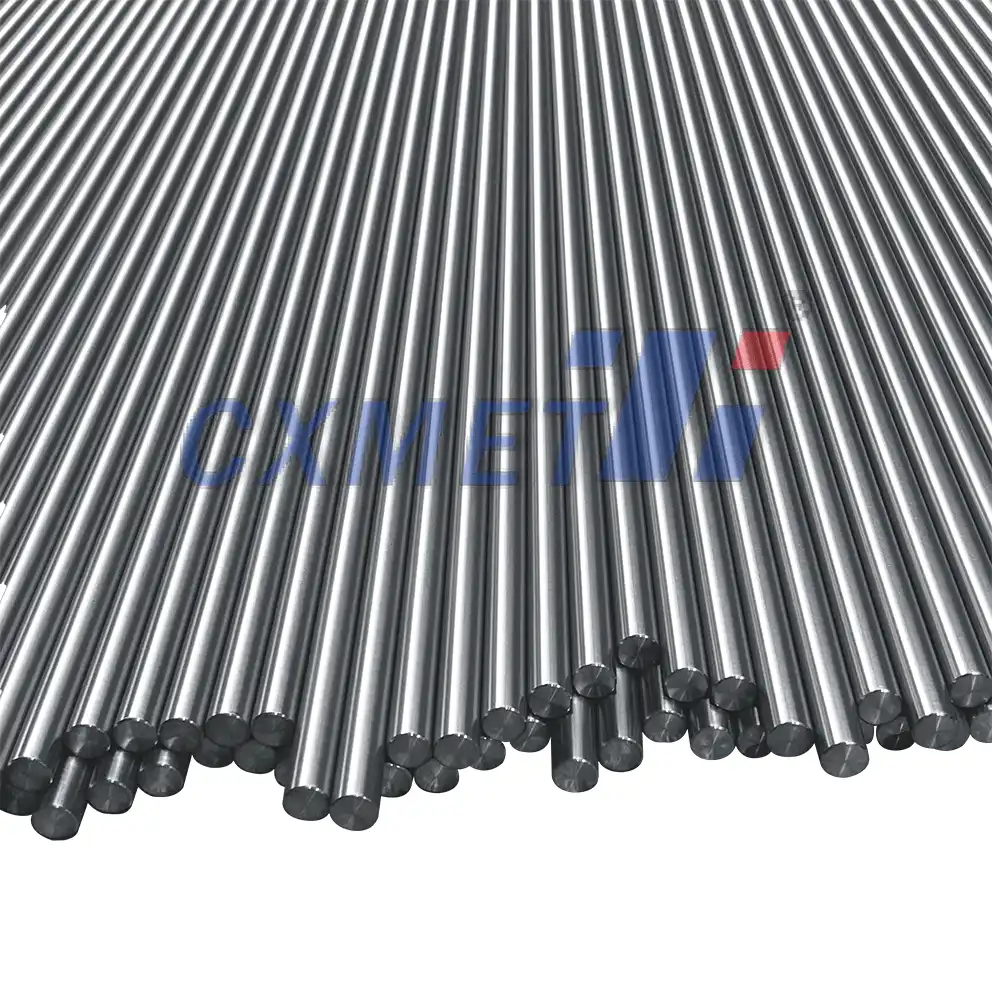

Zr702 zirconium rods are a crucial component in various industrial applications due to their exceptional properties. These rods are made from a specific grade of zirconium alloy known as Grade 702, which offers a unique combination of characteristics that make it suitable for use in demanding environments. In this blog post, we will explore the properties of Zr702 zirconium rods and discuss their applications, advantages, and key features.

How does the corrosion resistance of Zr702 zirconium rods compare to other materials?

One of the most notable properties of Zr702 zirconium rods is their exceptional corrosion resistance. This characteristic sets them apart from many other materials used in industrial applications, making them an ideal choice for environments where chemical resistance is paramount.

Zr702 zirconium rods exhibit superior corrosion resistance due to the formation of a stable, self-healing oxide layer on their surface. This protective layer, composed primarily of zirconium dioxide (ZrO2), acts as a barrier against various corrosive agents, including strong acids, alkalis, and organic compounds. The oxide layer quickly reforms if damaged, ensuring continuous protection throughout the material's service life.

When compared to other commonly used materials, Zr702 zirconium rods often outperform in terms of corrosion resistance:

- Stainless Steel: While stainless steel is known for its corrosion resistance, Zr702 zirconium rods offer superior protection against certain chemicals, particularly in high-temperature environments and in the presence of strong acids.

- Titanium: Although titanium is also highly corrosion-resistant, Zr702 zirconium rods demonstrate better resistance to certain aggressive media, such as hydrochloric acid and sulfuric acid at elevated temperatures.

- Nickel Alloys: Zr702 zirconium rods exhibit better resistance to stress corrosion cracking in chloride environments compared to many nickel alloys.

The exceptional corrosion resistance of Zr702 zirconium rods makes them particularly suitable for applications in the chemical processing industry, where they are used in heat exchangers, reaction vessels, and piping systems. They are also employed in the nuclear industry for fuel rod cladding and other components exposed to corrosive environments.

Furthermore, the corrosion resistance of Zr702 zirconium rods extends to high-temperature applications. Unlike some materials that may suffer from accelerated corrosion at elevated temperatures, Zr702 zirconium maintains its protective properties even in hot, aggressive environments. This characteristic makes it valuable in industries such as petrochemical processing and power generation.

It's worth noting that while Zr702 zirconium rods offer excellent corrosion resistance in many environments, they may not be suitable for all applications. For instance, they can be susceptible to hydrogen embrittlement under certain conditions, and their performance may be affected by the presence of fluoride ions. Therefore, it's essential to carefully evaluate the specific environmental conditions and chemical exposures when considering Zr702 zirconium rods for a particular application.

What are the mechanical properties of Zr702 zirconium rods?

The mechanical properties of Zr702 zirconium rods are a crucial aspect of their overall performance and contribute significantly to their suitability for various industrial applications. These properties determine the material's behavior under different types of stress and loading conditions, making them essential considerations for engineers and designers.

Tensile Strength: Zr702 zirconium rods exhibit good tensile strength, typically ranging from 380 to 550 MPa (55 to 80 ksi) in the annealed condition. This strength level makes them suitable for applications requiring moderate load-bearing capabilities. The tensile strength can be further increased through cold working, although this may affect other properties such as ductility.

Yield Strength: The yield strength of Zr702 zirconium rods is generally in the range of 205 to 380 MPa (30 to 55 ksi) for annealed material. This property is important for applications where the material needs to resist permanent deformation under load.

Elongation: Zr702 zirconium rods demonstrate excellent ductility, with elongation values typically ranging from 16% to 25% in the annealed condition. This high ductility allows for good formability and the ability to withstand plastic deformation without fracture.

Hardness: The hardness of Zr702 zirconium rods is typically in the range of 160-200 HV (Vickers Hardness). This moderate hardness contributes to the material's wear resistance while still allowing for machining and forming operations.

Modulus of Elasticity: The elastic modulus of Zr702 zirconium is approximately 95 GPa (13.8 x 10^6 psi), which is lower than that of steel or titanium. This lower stiffness can be advantageous in applications requiring some degree of flexibility or where stress distribution is a concern.

Fatigue Strength: Zr702 zirconium rods exhibit good fatigue resistance, making them suitable for applications involving cyclic loading. The fatigue strength is influenced by factors such as surface finish, temperature, and environmental conditions.

Creep Resistance: At elevated temperatures, Zr702 zirconium rods demonstrate good creep resistance, which is crucial for applications involving long-term exposure to high temperatures under load.

Impact Toughness: Zr702 zirconium possesses good impact toughness, particularly at low temperatures. This property is important for applications where the material may be subjected to sudden loads or impacts.

It's important to note that the mechanical properties of Zr702 zirconium rods can be influenced by factors such as temperature, processing history, and microstructure. For instance, the strength and hardness can be increased through cold working, but this may come at the expense of ductility. Additionally, the mechanical properties may change at elevated temperatures, which is an important consideration for high-temperature applications.

The combination of these mechanical properties makes Zr702 zirconium rods suitable for a wide range of applications, including chemical processing equipment, nuclear reactor components, and heat exchangers. Their good strength-to-weight ratio, coupled with excellent corrosion resistance, makes them particularly valuable in industries where both mechanical performance and chemical resistance are required.

How do the thermal properties of Zr702 zirconium rods affect their applications?

The thermal properties of Zr702 zirconium rods play a significant role in determining their suitability for various applications, particularly in high-temperature environments. Understanding these properties is crucial for engineers and designers when selecting materials for specific thermal conditions.

Melting Point: Zr702 zirconium has a relatively high melting point of approximately 1855°C (3371°F). This high melting point makes it suitable for applications involving elevated temperatures, where other materials might lose their structural integrity or mechanical properties.

Thermal Conductivity: The thermal conductivity of Zr702 zirconium is relatively low compared to many metals, typically around 22 W/m·K at room temperature. This property can be advantageous in applications where thermal insulation is desired, such as in certain nuclear reactor components. However, it may limit its use in heat exchange applications where high thermal conductivity is required.

Coefficient of Thermal Expansion: Zr702 zirconium has a low coefficient of thermal expansion, approximately 5.9 x 10^-6 /°C in the temperature range of 0-100°C. This low expansion rate helps maintain dimensional stability in applications involving temperature fluctuations, making it valuable in precision components and in situations where thermal stress must be minimized.

Specific Heat Capacity: The specific heat capacity of Zr702 zirconium is about 0.285 J/g·K at room temperature. This property influences the material's ability to absorb and release heat, which can be important in thermal management applications.

Thermal Stability: Zr702 zirconium exhibits good thermal stability, maintaining its mechanical properties and corrosion resistance at elevated temperatures. This stability is crucial for applications in high-temperature environments, such as in chemical processing equipment or nuclear reactors.

The thermal properties of Zr702 zirconium rods significantly impact their applications in various industries:

1. Nuclear Industry: In nuclear reactors, the low neutron absorption cross-section, combined with good thermal properties and corrosion resistance, makes Zr702 zirconium an excellent choice for fuel rod cladding and other core components. The material's ability to maintain its properties at high temperatures and under radiation exposure is crucial in this application.

2. Chemical Processing: The thermal stability and corrosion resistance of Zr702 zirconium rods make them suitable for use in high-temperature chemical processing equipment. They can withstand exposure to corrosive chemicals at elevated temperatures, where other materials might degrade or fail.

3. Heat Exchangers: While the relatively low thermal conductivity of Zr702 zirconium might limit its use in some heat exchange applications, its corrosion resistance and thermal stability make it valuable in specific scenarios, particularly where chemical compatibility is a primary concern.

4. Aerospace and High-Temperature Applications: The high melting point and low thermal expansion of Zr702 zirconium rods make them suitable for certain aerospace components and other high-temperature applications where dimensional stability is critical.

5. Optical and Electronic Industries: The low thermal expansion coefficient of Zr702 zirconium is advantageous in applications requiring precise dimensional control, such as in certain optical or electronic components.

It's important to note that while the thermal properties of Zr702 zirconium rods offer many advantages, they also present some limitations. For example, the relatively low thermal conductivity may necessitate careful design considerations in applications where heat transfer is critical. Additionally, at very high temperatures (above about 800°C), zirconium can react with atmospheric oxygen, forming a thick oxide layer that may affect its performance.

In conclusion, the thermal properties of Zr702 zirconium rods, including their high melting point, low thermal expansion, and good thermal stability, make them well-suited for a range of high-temperature and thermally demanding applications. However, as with any material selection, it's crucial to consider the specific requirements of each application and evaluate how the thermal properties of Zr702 zirconium align with these needs.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

- ATI Metals. (2021). Zirconium Alloy Technical Data Sheet.

- World Nuclear Association. (2021). Zirconium Alloys in Nuclear Technology.

- ASM International. (2018). ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

- Akhiani, H., & Szpunar, J. A. (2019). Effect of heat treatment on the corrosion resistance of Zr-2.5 Nb alloy. Journal of Nuclear Materials, 518, 177-186.

- Corrosion Materials. (2021). Zirconium Properties and Applications.

- ASTM International. (2020). ASTM B551/B551M-20 Standard Specification for Zirconium and Zirconium Alloy Strip, Sheet, and Plate.

- Trickel, T. (2017). Zirconium in the Nuclear Industry: 18th International Symposium. ASTM International.

- Lemaignan, C., & Motta, A. T. (2006). Zirconium Alloys in Nuclear Applications. Materials Science and Technology.

- Whitmarsh, C. L. (1962). Review of Zircaloy-2 and Zircaloy-4 Properties Relevant to N.S. Savannah Reactor Design. Oak Ridge National Laboratory.

- Lustman, B., & Kerze, F. (1955). The Metallurgy of Zirconium. McGraw-Hill.