- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Safety Precautions Needed When Handling Tantalum Foil?

2024-08-02 17:08:10

Tantalum foil is a versatile material widely used in various industries due to its exceptional properties. However, handling this material requires specific safety precautions to protect workers and ensure safe operations. This blog post will explore the essential safety measures needed when working with Tantalum foil, as well as delve into its unique properties, industrial applications, and potential health risks.

What are the unique properties of Tantalum foil?

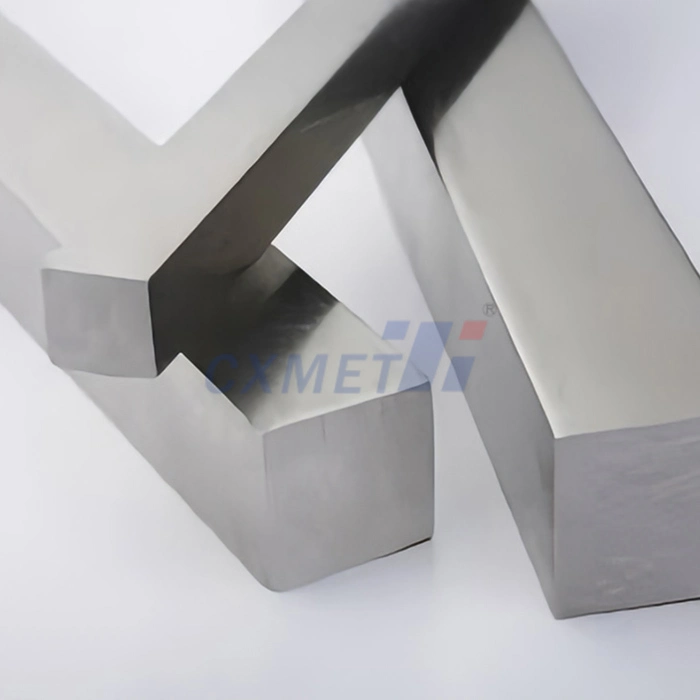

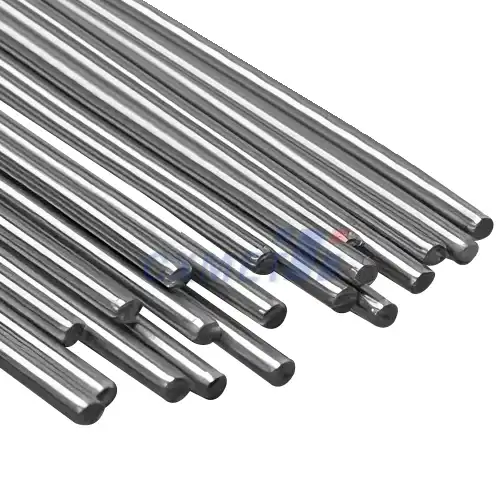

Tantalum foil possesses a remarkable combination of physical and chemical properties that make it highly valuable in numerous applications. This silvery-blue metal is known for its exceptional corrosion resistance, high melting point, and excellent ductility. Tantalum foil typically ranges in thickness from a few micrometers to several millimeters, offering flexibility in its use across different industries.

One of the most notable characteristics of Tantalum foil is its outstanding resistance to chemical attack. It can withstand exposure to most acids, alkalies, and organic compounds, making it an ideal choice for applications involving harsh chemical environments. This resistance is attributed to the formation of a thin, protective oxide layer on the surface of the metal when exposed to air.

The high melting point of Tantalum, approximately 3,017°C (5,463°F), contributes to its stability at elevated temperatures. This property makes Tantalum foil suitable for use in high-temperature applications, such as furnace components and heat exchangers. Additionally, its low vapor pressure at high temperatures allows it to maintain its integrity in vacuum environments.

Tantalum foil also exhibits excellent ductility and malleability, allowing it to be easily formed into various shapes without compromising its structural integrity. This characteristic is particularly useful in the production of complex components for electronic devices and medical implants.

Furthermore, Tantalum possesses a high capacitance per unit volume, making it an excellent material for manufacturing capacitors. Tantalum foil capacitors are known for their reliability, stability, and long service life, which are crucial factors in electronic applications.

The unique combination of these properties – corrosion resistance, high melting point, ductility, and electrical characteristics – makes Tantalum foil an invaluable material in numerous industries. However, these same properties also necessitate specific handling precautions to ensure worker safety and maintain the integrity of the material during processing and use.

How is Tantalum foil used in various industries?

Tantalum foil finds applications across a wide range of industries due to its exceptional properties. Its versatility and reliability make it a preferred material in several high-tech and specialized fields. Let's explore some of the key industries where Tantalum foil plays a crucial role:

1. Electronics Industry:

In the electronics sector, Tantalum foil is primarily used in the production of capacitors. Tantalum capacitors are renowned for their high capacitance in a small volume, stability over a wide temperature range, and long operational life. These characteristics make them ideal for use in portable electronic devices, automotive electronics, and aerospace applications. The foil's thinness allows for the creation of compact capacitors that can store large amounts of electrical charge, contributing to the miniaturization of electronic components.

2. Chemical Processing Industry:

The exceptional corrosion resistance of Tantalum foil makes it invaluable in chemical processing equipment. It is used to line reactors, heat exchangers, and storage tanks that handle corrosive chemicals. Tantalum foil linings protect the underlying structural materials from degradation, extending the lifespan of equipment and ensuring the purity of processed chemicals. This application is particularly important in the production of pharmaceuticals, where material purity is paramount.

3. Aerospace and Defense:

The aerospace and defense industries utilize Tantalum foil for its high-temperature stability and strength-to-weight ratio. It is used in the fabrication of missile components, rocket nozzles, and heat shields. The foil's ability to withstand extreme temperatures and resist oxidation makes it suitable for use in turbine blades and other critical engine components in aircraft.

4. Medical Industry:

Tantalum's biocompatibility and corrosion resistance make it an excellent material for medical implants. Tantalum foil is used in the production of surgical staples, bone implants, and neurosurgical clips. Its ability to form a stable oxide layer prevents reactions with bodily fluids, reducing the risk of rejection or allergic reactions in patients.

5. Semiconductor Industry:

In semiconductor manufacturing, Tantalum foil is used as a diffusion barrier in integrated circuits. It prevents the migration of copper interconnects into the silicon substrate, maintaining the integrity and performance of microchips. The foil's high melting point also makes it suitable for use in sputtering targets for thin film deposition processes.

6. Nuclear Industry:

The nuclear industry employs Tantalum foil in various applications due to its resistance to radiation damage and corrosion. It is used in nuclear reactor components, fuel rod cladding, and radiation shielding. The foil's ability to maintain its structural integrity under high-radiation environments makes it a valuable material in this sector.

7. Optical Coatings:

Tantalum foil is used in the production of optical coatings for lenses and mirrors. When deposited as a thin film, it provides excellent adhesion, hardness, and optical properties. These coatings are used in camera lenses, telescopes, and other optical instruments to improve light transmission and reduce reflections.

8. Energy Storage:

In addition to capacitors, Tantalum foil is being explored for use in advanced energy storage technologies. Its high surface area and stability make it a potential candidate for electrode materials in next-generation batteries and supercapacitors.

The diverse applications of Tantalum foil across these industries underscore its importance as a high-performance material. However, its widespread use also highlights the need for proper handling and safety precautions to protect workers and maintain the material's integrity throughout its lifecycle.

What are the potential health risks associated with Tantalum exposure?

While Tantalum is generally considered to have low toxicity compared to many other metals, exposure to Tantalum foil and its compounds can still pose potential health risks, particularly in occupational settings where higher levels of exposure may occur. Understanding these risks is crucial for implementing appropriate safety measures and protecting workers' health.

1. Inhalation Risks:

The primary route of concern for Tantalum exposure is through inhalation of dust or fumes generated during the processing or handling of Tantalum foil. When Tantalum particles are inhaled, they can deposit in the lungs and respiratory tract. Prolonged exposure to Tantalum dust has been associated with pneumoconiosis, a lung disease characterized by the accumulation of dust in the lungs and the tissue's reaction to its presence. Symptoms may include coughing, shortness of breath, and decreased lung function.

2. Skin and Eye Irritation:

Direct contact with Tantalum foil or dust may cause mechanical irritation to the skin and eyes. While Tantalum itself is not typically considered a skin sensitizer, repeated or prolonged contact could lead to dermatitis in some individuals. Eye exposure to Tantalum particles can cause irritation, redness, and potentially corneal abrasions if proper eye protection is not used.

3. Ingestion Hazards:

Although less common than inhalation or skin exposure, accidental ingestion of Tantalum particles can occur, particularly if proper hygiene practices are not followed in the workplace. While Tantalum is generally considered to have low oral toxicity, ingestion of large amounts could potentially cause gastrointestinal irritation.

4. Chronic Health Effects:

Long-term exposure to Tantalum and its compounds has been the subject of ongoing research. Some studies have suggested potential links between chronic Tantalum exposure and effects on the liver, kidneys, and central nervous system. However, the evidence for these effects is limited, and more research is needed to fully understand the long-term health implications of Tantalum exposure.

5. Carcinogenicity:

Currently, there is insufficient evidence to classify Tantalum as a carcinogen. Neither the International Agency for Research on Cancer (IARC) nor the U.S. National Toxicology Program has listed Tantalum as a known or suspected carcinogen. However, as with many industrial materials, long-term studies on its carcinogenic potential are ongoing.

6. Reproductive and Developmental Effects:

Limited data is available on the reproductive and developmental toxicity of Tantalum. Some animal studies have suggested potential effects on fetal development at high exposure levels, but the relevance of these findings to human exposure scenarios is unclear.

7. Radioactivity Concerns:

While Tantalum itself is not radioactive, it is often found in ores alongside naturally occurring radioactive materials. In some cases, trace amounts of radioactive elements may be present in Tantalum products. However, the levels are typically very low and do not pose a significant radiation hazard under normal use conditions.

8. Interaction with Other Substances:

In industrial settings, Tantalum may be used alongside other potentially hazardous materials. The combined effects of exposure to Tantalum and other substances should be considered when assessing overall health risks in the workplace.

Given these potential health risks, it is essential to implement proper safety precautions when handling Tantalum foil. These measures should include:

- Use of appropriate personal protective equipment (PPE), including respirators, gloves, and eye protection.

- Implementation of engineering controls such as local exhaust ventilation to minimize dust and fume exposure.

- Regular workplace monitoring to ensure exposure levels remain below established occupational exposure limits.

- Proper training for workers on the safe handling of Tantalum foil and associated health risks.

- Adherence to good hygiene practices, including washing hands thoroughly after handling Tantalum materials and before eating, drinking, or smoking.

- Regular medical surveillance for workers with potential for high or prolonged exposure to Tantalum.

By understanding and addressing these potential health risks, industries can ensure the safe use of Tantalum foil while harnessing its valuable properties for various applications. Ongoing research and vigilance in occupational health practices will continue to inform best practices for Tantalum handling and worker protection.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Balakrishnan, M., & Krishnan, R. (2015). Tantalum—Raw Material, Technologies and Applications. In Rare Metal Technology 2015 (pp. 61-71). Springer, Cham.

2. Cardarelli, F. (2018). Materials handbook: a concise desktop reference. Springer.

3. Chua, D. Y., & Chu, P. K. (2018). Tantalum-based thin films for biomedical applications. In Thin Film Coatings for Biomaterials and Biomedical Applications (pp. 261-285). Woodhead Publishing.

4. Entwistle, K. M. (2012). Basic principles of the finite element method. Routledge.

5. Gargulak, J. D., & Gladysz, G. M. (2019). Tantalum and niobium-based materials for electronics. In Advanced Micro-and Nanomaterials for Photovoltaics (pp. 379-415). Elsevier.

6. Krebs, R. E. (2006). The history and use of our earth's chemical elements: a reference guide. Greenwood Publishing Group.

7. Matsuno, H., Yokoyama, A., Watari, F., Uo, M., & Kawasaki, T. (2001). Biocompatibility and osteogenesis of refractory metal implants, titanium, hafnium, niobium, tantalum and rhenium. Biomaterials, 22(11), 1253-1262.

8. Naidu, M. S. (2018). High voltage engineering. Tata McGraw-Hill Education.

9. Papp, J. F. (2014). Tantalum and niobium. In Critical Metals Handbook (pp. 355-384). John Wiley & Sons.

10. Zednicek, T., Zednicek, S., & Sita, Z. (2017). Tantalum and niobium technology roadmap. In Future Trends in Microelectronics: Journey into the Unknown (pp. 23-37). John Wiley & Sons.