- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Typical Applications of Grade 5 Titanium Alloy Tubes?

2024-08-21 17:22:00

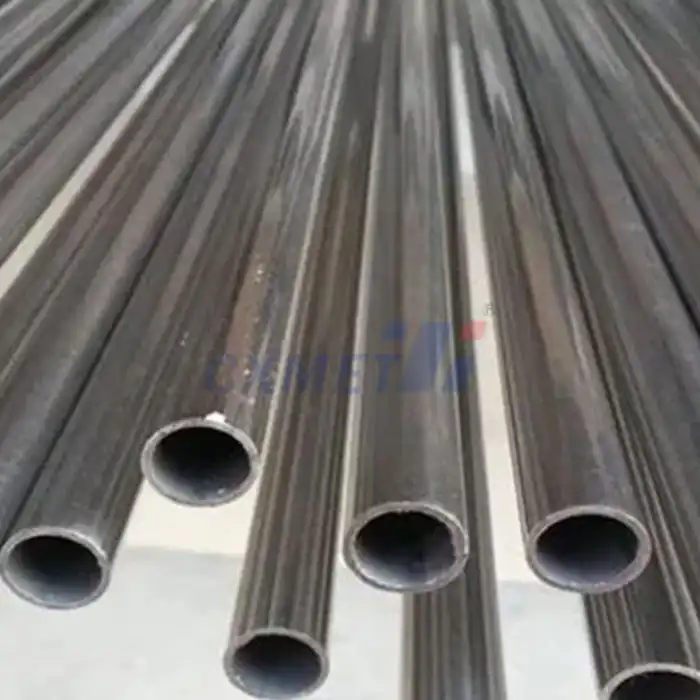

Titanium alloys have long been recognized for their exceptional strength, corrosion resistance, and lightweight properties, making them a popular choice in various industries. Among the different grades of titanium alloys, Grade 5 (also known as Ti-6Al-4V) has emerged as a standout performer, offering a unique combination of desirable characteristics that have led to its widespread adoption across various applications.

What Makes Grade 5 Titanium Alloy Tubes Unique?

Grade 5 titanium alloy tubes are prized for their exceptional mechanical properties, which are a result of their chemical composition and the manufacturing process used to produce them. These tubes are made from a titanium alloy that contains approximately 6% aluminum and 4% vanadium, which gives them superior strength and durability compared to commercially pure titanium.

One of the key features of Grade 5 titanium alloy tubes is their high strength-to-weight ratio. This means that they are incredibly strong while still being relatively lightweight, making them an ideal choice for applications where weight is a critical factor. This property is particularly advantageous in industries such as aerospace, where every ounce of weight saved can translate into significant fuel savings and improved performance.

In addition to their impressive strength, Grade 5 titanium alloy tubes also exhibit excellent corrosion resistance. The titanium oxide layer that forms on the surface of these tubes acts as a protective barrier, shielding the underlying material from the effects of environmental factors such as moisture, chemicals, and salt. This makes them well-suited for use in harsh or corrosive environments, where other materials may quickly degrade.

Another notable characteristic of Grade 5 titanium alloy tubes is their biocompatibility. This property is particularly important in medical applications, where the tubes may be used in implants or other devices that come into direct contact with the human body. The biocompatibility of Grade 5 titanium ensures that it can be safely used in these sensitive applications without causing adverse reactions or complications.

How Are Grade 5 Titanium Alloy Tubes Used in the Aerospace Industry?

The aerospace industry is one of the primary consumers of Grade 5 titanium alloy tubes, taking advantage of the material's exceptional strength, lightweight, and corrosion resistance. These tubes are used in a wide range of aircraft components, from airframes and landing gear to engine components and hydraulic systems.

One of the most common applications of Grade 5 titanium alloy tubes in the aerospace industry is in the construction of airframes. The high strength-to-weight ratio of these tubes allows for the creation of lightweight, yet incredibly durable aircraft structures that can withstand the stresses of flight. This, in turn, leads to improved fuel efficiency and increased payload capacity, both of which are critical factors in the design and performance of modern aircraft.

Grade 5 titanium alloy tubes are also widely used in the construction of aircraft landing gear. The strength and corrosion resistance of these tubes make them well-suited for the harsh environments encountered during takeoffs and landings, where the landing gear is subjected to significant stresses and exposure to various environmental factors.

In addition to airframe and landing gear components, Grade 5 titanium alloy tubes are also used in the manufacture of engine components, such as turbine blades and compressor discs. The high-temperature resistance and creep properties of these tubes allow them to withstand the extreme conditions found within aircraft engines, ensuring reliable and efficient performance.

Furthermore, Grade 5 titanium alloy tubes are also used in the construction of various hydraulic systems found in aircraft, including landing gear actuation systems, flight control systems, and fuel systems. The corrosion resistance and durability of these tubes help to ensure the reliable operation of these critical systems, which are essential for the safe and efficient operation of modern aircraft.

What Are the Benefits of Using Grade 5 Titanium Alloy Tubes in Medical Devices?

The medical industry has also embraced the use of Grade 5 titanium alloy tubes, taking advantage of the material's unique properties to create a wide range of innovative medical devices and implants.

One of the primary benefits of using Grade 5 titanium alloy tubes in medical applications is their biocompatibility. The titanium oxide layer that forms on the surface of these tubes is highly compatible with the human body, minimizing the risk of adverse reactions or rejection. This makes them an ideal choice for use in implants and other medical devices that come into direct contact with the body.

Another key advantage of Grade 5 titanium alloy tubes in medical applications is their strength and durability. These tubes can withstand the stresses and loads imposed by the human body, ensuring that medical devices and implants made from them remain stable and functional over extended periods. This is particularly important in applications such as orthopedic implants, where the materials used must be able to support the weight and movement of the patient.

In addition to their strength and biocompatibility, Grade 5 titanium alloy tubes also offer excellent corrosion resistance, which is essential in medical applications. The human body is a highly corrosive environment, with various fluids and chemicals that can quickly degrade other materials. By using Grade 5 titanium alloy tubes, medical device manufacturers can ensure that their products maintain their integrity and functionality, even in this challenging environment.

One of the most common applications of Grade 5 titanium alloy tubes in the medical industry is in the construction of orthopedic implants, such as hip and knee replacements. The strength and biocompatibility of these tubes make them an ideal choice for these types of implants, which must be able to withstand the significant loads and stresses placed on them by the human body.

Grade 5 titanium alloy tubes are also used in the manufacture of various medical instruments and tools, such as surgical tools, dental implants, and prosthetic limbs. The corrosion resistance and durability of these tubes help to ensure the reliable performance and long-term functionality of these critical medical devices.

Furthermore, the lightweight nature of Grade 5 titanium alloy tubes makes them particularly well-suited for use in medical devices that need to be easily maneuvered or worn by the patient, such as orthopedic braces and prosthetic limbs. By reducing the overall weight of these devices, manufacturers can improve the comfort and mobility of patients, enhancing their quality of life.

In conclusion, the unique properties of Grade 5 titanium alloy tubes make them a highly sought-after material in the medical industry, with a wide range of applications that leverage their strength, biocompatibility, corrosion resistance, and lightweight characteristics.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

2. Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

3. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH.

4. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer.

5. Fanning, J. C. (2005). Properties of Ti-6Al-4V. JOM, 57(9), 32-34.

6. Niinomi, M. (1998). Mechanical properties of biomedical titanium alloys. Materials Science and Engineering: A, 243(1-2), 231-236.

7. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants–a review. Progress in Materials Science, 54(3), 397-425.

8. Banerjee, R., Nag, S., & Fraser, H. L. (2005). A novel combinatorial approach to the development of beta titanium alloys for orthopaedic implants. Materials Science and Engineering: C, 25(3), 282-289.

9. Eisenbarth, E., Velten, D., Müller, M., Thull, R., & Breme, J. (2004). Biocompatibility of beta-stabilizing elements of titanium alloys. Biomaterials, 25(26), 5705-5713.

10. Kuroda, D., Niinomi, M., Morinaga, M., Kato, Y., & Yashiro, T. (1998). Design and mechanical properties of new β type titanium alloys for implant materials. Materials Science and Engineering: A, 243(1-2), 244-249.