- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Diameters And Lengths Are Available For Niobium Wire?

2025-01-03 14:56:02

Niobium wire is a versatile and highly sought-after material in various industries due to its unique properties. When it comes to the availability of niobium wire, manufacturers offer a wide range of diameters and lengths to cater to different applications and requirements. This blog post will explore the various dimensions of niobium wire available in the market and discuss their applications, manufacturing processes, and factors influencing their selection.

How is niobium wire manufactured?

The manufacturing process of niobium wire is a complex and precise procedure that involves several steps to ensure the production of high-quality wire with desired properties. The process typically begins with the extraction of niobium from its ore, followed by purification and refinement to obtain pure niobium metal.

The first step in wire manufacturing is the creation of a niobium ingot through melting and casting. This ingot is then subjected to a series of hot and cold working processes to reduce its diameter and increase its length. The most common methods used for this purpose include:

- Hot extrusion: The niobium ingot is heated to high temperatures and forced through a die to create a long, thin rod.

- Cold drawing: The extruded rod is pulled through progressively smaller dies at room temperature to further reduce its diameter and increase its length.

- Annealing: Intermediate heat treatments are performed to relieve internal stresses and maintain the wire's ductility during the drawing process.

The cold drawing process is repeated multiple times until the desired wire diameter is achieved. This process not only reduces the wire's diameter but also improves its mechanical properties, such as tensile strength and uniformity.

For ultra-fine niobium wires, advanced techniques like bundle drawing may be employed. In this method, multiple niobium wires are bundled together and drawn as a single unit, allowing for the production of extremely thin wires with diameters as small as a few micrometers.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the wire meets the required specifications. This includes regular inspections, dimensional checks, and testing of mechanical and electrical properties.

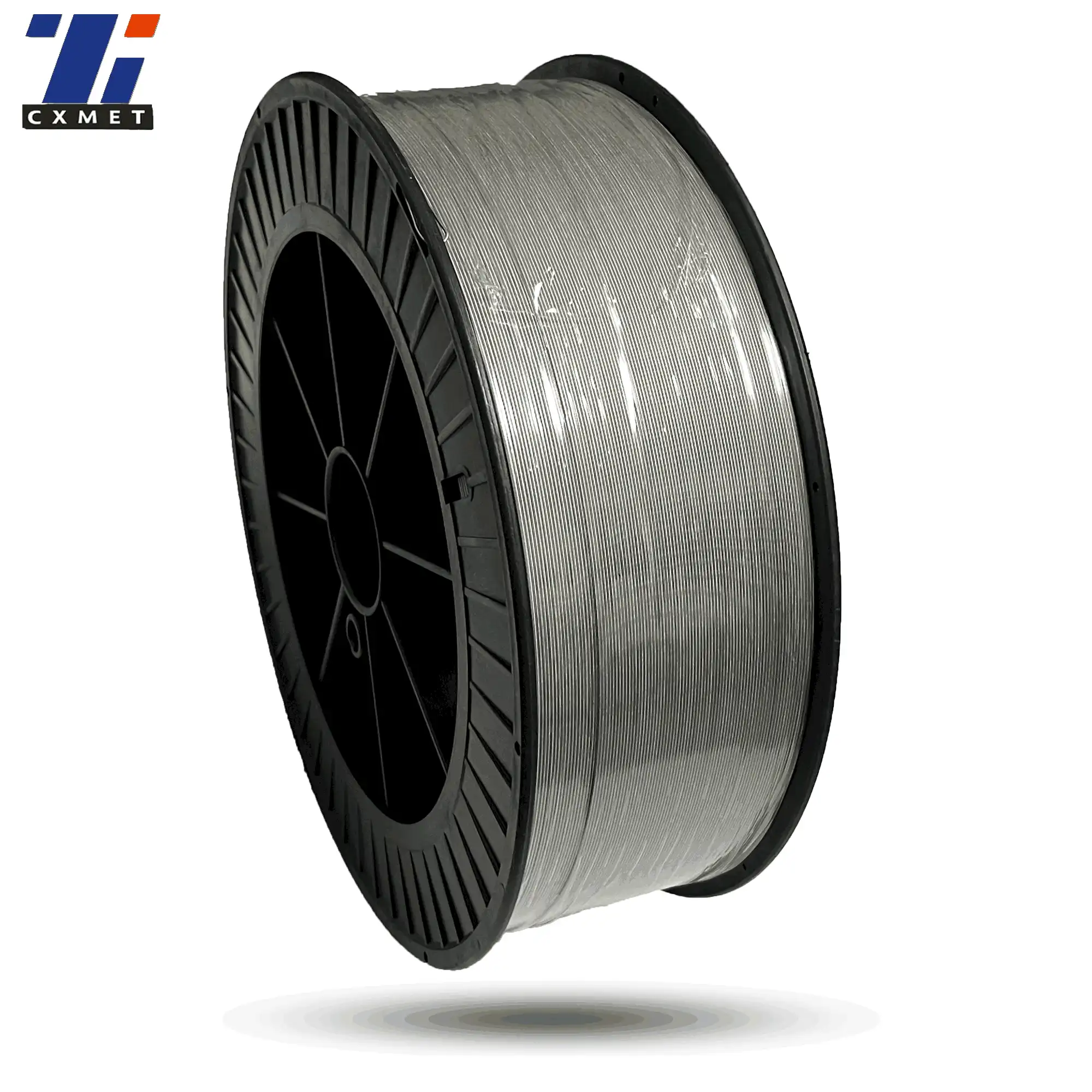

The final step in the manufacturing process involves spooling or coiling the wire for packaging and shipping. Depending on the customer's requirements, the wire may be cut to specific lengths or supplied in continuous lengths on spools.

What are the typical applications for different niobium wire diameters?

Niobium wire finds applications in various industries due to its unique combination of properties, including high corrosion resistance, excellent ductility, and superconductivity at low temperatures. The specific diameter of niobium wire chosen for a particular application depends on the intended use and the required performance characteristics.

Here are some typical applications for different niobium wire diameters:

- Thin wires (0.01 mm to 0.1 mm):

- Superconducting magnets for MRI machines and particle accelerators

- Thin film deposition in the semiconductor industry

- Microelectronics and nanotechnology research

- Fine wire mesh for filtration applications

- Medium wires (0.1 mm to 1 mm):

- Jewelry making, particularly for hypoallergenic body piercings

- Electrical contacts in harsh environments

- Cathodes in high-power electron tubes

- Welding electrodes for specialized applications

- Thick wires (1 mm and above):

- Structural components in high-temperature furnaces

- Corrosion-resistant equipment in chemical processing

- Electrodes for metal refining and electroplating

- Getters in vacuum systems

The choice of wire diameter also depends on factors such as the required mechanical strength, electrical conductivity, and thermal properties for the specific application. For instance, thinner wires are often preferred in applications where flexibility and low mass are crucial, while thicker wires are used when higher mechanical strength or current-carrying capacity is needed.

In the field of superconductivity, niobium-titanium (NbTi) and niobium-tin (Nb3Sn) wires are widely used. These alloys are often produced in multifilamentary form, where numerous thin filaments of the superconducting material are embedded in a copper matrix. The diameter of individual filaments can be as small as a few micrometers, while the overall wire diameter may range from 0.1 mm to several millimeters, depending on the specific magnet design requirements.

How does the length of niobium wire affect its performance and cost?

The length of niobium wire plays a significant role in both its performance characteristics and cost considerations. Understanding these factors is crucial for manufacturers and end-users to optimize their use of niobium wire in various applications.

Performance considerations:

- Electrical resistance: The length of a wire directly affects its electrical resistance. Longer wires have higher resistance, which can be a critical factor in electrical and electronic applications. In superconducting applications, where niobium wire is often used, the length must be carefully considered to maintain the desired superconducting properties throughout the entire wire length.

- Mechanical properties: As the length of niobium wire increases, maintaining uniform mechanical properties throughout the wire becomes more challenging. Longer wires may exhibit slight variations in diameter, tensile strength, or ductility along their length due to the manufacturing process.

- Thermal characteristics: In applications where heat dissipation is important, the length of the wire affects its overall thermal performance. Longer wires have more surface area for heat dissipation but may also experience greater temperature gradients along their length.

- Magnetic field uniformity: In superconducting magnet applications, the length of niobium wire used in coil windings directly impacts the uniformity and strength of the generated magnetic field. Precise control of wire length is crucial for achieving the desired magnetic field characteristics.

Cost considerations:

- Material cost: Niobium is a relatively expensive metal, and the cost of niobium wire is directly proportional to its length. Longer wires require more raw material, increasing the overall cost of the product.

- Manufacturing complexity: Producing longer continuous lengths of niobium wire can be more challenging and may require specialized equipment or techniques. This increased manufacturing complexity can contribute to higher production costs.

- Quality control: Ensuring consistent quality over longer wire lengths requires more extensive testing and inspection procedures, which can add to the overall cost of production.

- Handling and packaging: Longer wires may require special handling and packaging considerations to prevent damage during transportation and storage, potentially increasing logistical costs.

- Waste reduction: In some applications, the ability to procure niobium wire in specific lengths can help reduce waste and optimize material usage, potentially leading to cost savings for end-users.

When selecting niobium wire for a particular application, it's essential to balance the performance requirements with cost considerations. In some cases, using multiple shorter lengths of wire may be more cost-effective than a single long wire, especially if the application allows for joins or connections.

Manufacturers often offer niobium wire in standard lengths, typically ranging from a few meters to several hundred meters, depending on the wire diameter. Custom lengths can usually be provided upon request, although this may impact pricing and lead times.

For applications requiring very long lengths of niobium wire, such as large superconducting magnets, specialized manufacturing techniques may be employed to produce continuous lengths of wire measuring several kilometers. These advanced production methods often involve sophisticated quality control measures to ensure consistent performance over the entire wire length.

Conclusion

Niobium wire is available in a wide range of diameters and lengths to suit various applications across multiple industries. The manufacturing process, typical applications, and the impact of length on performance and cost are all critical factors to consider when selecting niobium wire for a specific purpose. By understanding these aspects, engineers and researchers can make informed decisions to optimize the use of niobium wire in their projects, balancing performance requirements with cost considerations.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

- ASTM B392 - Standard Specification for Niobium and Niobium Alloy Bar, Rod, and Wire

- Patel, D., & Al-Jabr, A. (2019). Evaluating the use of niobium to improve the properties of superconducting radio frequency cavities. Superconductor Science and Technology, 32(1), 015007.

- Alam, M. A., et al. (2020). Niobium and its alloys for superconducting radio frequency cavities. Journal of Alloys and Compounds, 844, 156172.

- Lee, P. J. (2001). Engineering superconductivity: From niobium-titanium wires to magnet systems. IEEE Transactions on Applied Superconductivity, 11(1), 3613-3616.

- Foner, S., & Schwartz, B. B. (Eds.). (2013). Superconductor materials science: metallurgy, fabrication, and applications. Springer Science & Business Media.

- Welsch, G., Boyer, R., & Collings, E. W. (Eds.). (2007). Materials properties handbook: titanium alloys. ASM international.

- Peng, X., et al. (2015). Fabrication of high-quality Nb3Sn strands for high-field accelerator magnets. IEEE Transactions on Applied Superconductivity, 25(3), 1-5.

- Godeke, A. (2006). A review of the properties of Nb3Sn and their variation with A15 composition, morphology and strain state. Superconductor Science and Technology, 19(8), R68.

- Scanlan, R. M., Malozemoff, A. P., & Larbalestier, D. C. (2004). Superconducting materials for large scale applications. Proceedings of the IEEE, 92(10), 1639-1654.

- Flükiger, R., et al. (2008). Optimization of Nb3Sn and MgB2 wires. Superconductor Science and Technology, 21(5), 054015.

.webp)