- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Industries Use Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar?

2024-09-09 14:36:07

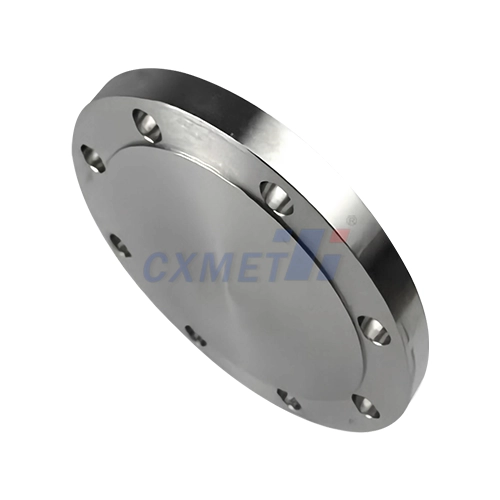

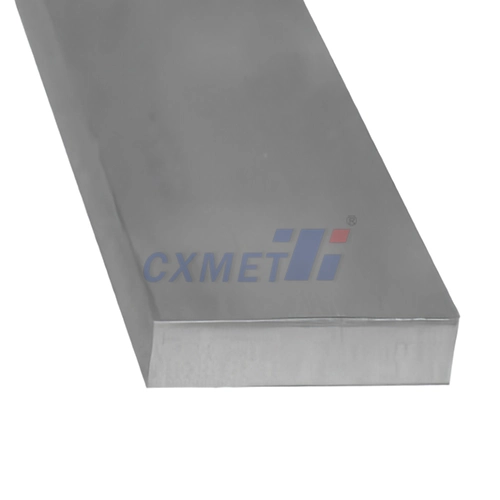

Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar, often referred to as Ti 6-2-4-6, is a high-strength titanium alloy known for its exceptional mechanical properties and resistance to corrosion. This versatile material has found applications across various industries due to its unique combination of strength, lightweight characteristics, and ability to withstand extreme conditions. In this blog post, we'll explore the diverse range of industries that rely on Ti 6-2-4-6 round bar and delve into its specific applications and benefits.

What are the key properties of Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar?

Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar is a complex alloy designed to offer superior performance in demanding environments. Its composition includes 6% aluminum, 2% tin, 4% zirconium, and 6% molybdenum, with the balance being titanium. This carefully engineered blend of elements results in a material with extraordinary properties that make it highly sought after in various industrial applications.

One of the most notable characteristics of Ti 6-2-4-6 is its exceptional strength-to-weight ratio. This alloy boasts a high tensile strength, typically ranging from 1030 to 1100 MPa (150 to 160 ksi), while maintaining a relatively low density of about 4.54 g/cm³. This combination makes it an ideal choice for applications where weight reduction is crucial without compromising structural integrity.

The alloy also exhibits excellent resistance to corrosion and oxidation, even at elevated temperatures. It can maintain its strength and stability in environments up to 540°C (1000°F), making it suitable for high-temperature applications. This heat resistance is particularly valuable in aerospace and industrial settings where components are subjected to extreme thermal conditions.

Furthermore, Ti 6-2-4-6 demonstrates good fatigue strength and fracture toughness, which are critical properties for components subjected to cyclic loading or potential impact scenarios. Its ability to withstand repeated stress without failure contributes to the longevity and reliability of parts made from this alloy.

The unique combination of these properties – high strength, low weight, corrosion resistance, and thermal stability – makes Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar an exceptional material for industries that demand peak performance under challenging conditions.

How is Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar used in the aerospace industry?

The aerospace industry is one of the primary sectors that extensively utilizes Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar. The alloy's exceptional strength-to-weight ratio makes it an ideal material for aircraft and spacecraft components where every gram of weight saved translates to improved fuel efficiency and performance.

In commercial and military aircraft, Ti 6-2-4-6 round bar is commonly used in the manufacturing of critical structural components. These include landing gear assemblies, wing attachments, and engine mounts. The alloy's high strength allows it to withstand the enormous stresses experienced during takeoff, landing, and in-flight maneuvers, while its lightweight nature helps reduce the overall mass of the aircraft.

For jet engines, Ti 6-2-4-6 is a preferred material for compressor blades and discs. These components operate in high-temperature environments and are subjected to significant centrifugal forces. The alloy's ability to maintain its mechanical properties at elevated temperatures, combined with its resistance to fatigue, makes it well-suited for these demanding applications.

In the realm of space exploration, Ti 6-2-4-6 finds applications in satellite structures, propulsion systems, and even in the construction of spacecraft components. The material's corrosion resistance is particularly valuable in the harsh environment of space, where exposure to atomic oxygen and other corrosive elements can degrade less resilient materials.

The use of Ti 6-2-4-6 in aerospace extends beyond structural components. It is also employed in the fabrication of fasteners, bolts, and other critical joining elements. These small but crucial parts benefit from the alloy's high strength and resistance to stress corrosion cracking, ensuring the integrity of aerospace structures over long periods of operation.

Moreover, the aerospace industry's continuous push for more efficient and environmentally friendly aircraft has led to increased adoption of titanium alloys like Ti 6-2-4-6. As manufacturers seek to reduce fuel consumption and emissions, the use of lightweight yet strong materials becomes increasingly important. Ti 6-2-4-6 round bar allows engineers to design components that meet stringent performance requirements while contributing to the overall goal of creating more sustainable aircraft.

What role does Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar play in the medical industry?

While not as prominently used as some other titanium alloys in the medical field, Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar has found niche applications in certain areas of medical technology and device manufacturing. The alloy's biocompatibility, coupled with its high strength and corrosion resistance, makes it a valuable material for specific medical applications.

One area where Ti 6-2-4-6 has shown potential is in the development of high-performance surgical instruments. The alloy's exceptional strength and durability allow for the creation of tools that can withstand repeated sterilization cycles without degradation. Surgical instruments made from this alloy can maintain their precision and effectiveness over extended periods of use, which is crucial in medical settings where reliability is paramount.

In orthopedic implants, while Ti-6Al-4V remains the more common choice, Ti 6-2-4-6 has been explored for specialized applications that require higher strength and wear resistance. For instance, it has been considered for use in certain joint replacement components, particularly those subjected to high stress and wear, such as in hip or knee implants for more active or heavier patients.

The alloy's resistance to corrosion in bodily fluids is another factor that makes it suitable for long-term implantation. This property helps ensure that the implant remains stable and does not release harmful metal ions into the surrounding tissues, which is a critical consideration for any material used in medical implants.

In the field of dental implantology, Ti 6-2-4-6 has been studied for potential use in dental implant systems. Its high strength could allow for the development of smaller, yet equally strong implants, which could be beneficial in cases where bone volume is limited or in aesthetic zones where space is at a premium.

The medical industry also benefits from Ti 6-2-4-6 in the manufacturing of medical imaging equipment. Components in MRI machines, X-ray devices, and other diagnostic tools can be made from this alloy, taking advantage of its non-magnetic properties and structural integrity.

Research into the use of Ti 6-2-4-6 in medical applications is ongoing, with scientists and engineers exploring new ways to leverage its unique properties. As medical technology continues to advance, demanding ever more sophisticated materials, alloys like Ti 6-2-4-6 may find expanded roles in the development of next-generation medical devices and implants.

While its use in the medical industry may not be as widespread as in aerospace or industrial applications, Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar demonstrates the potential to contribute to advancements in medical technology, particularly in areas where high strength, durability, and biocompatibility are essential.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

1. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

2. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

3. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

4. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

5. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

6. Banerjee, D., & Williams, J. C. (2013). Perspectives on titanium science and technology. Acta Materialia, 61(3), 844-879.

7. Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.

8. Froes, F. H. (Ed.). (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

9. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons.

10. Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 1(1), 30-42.