- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

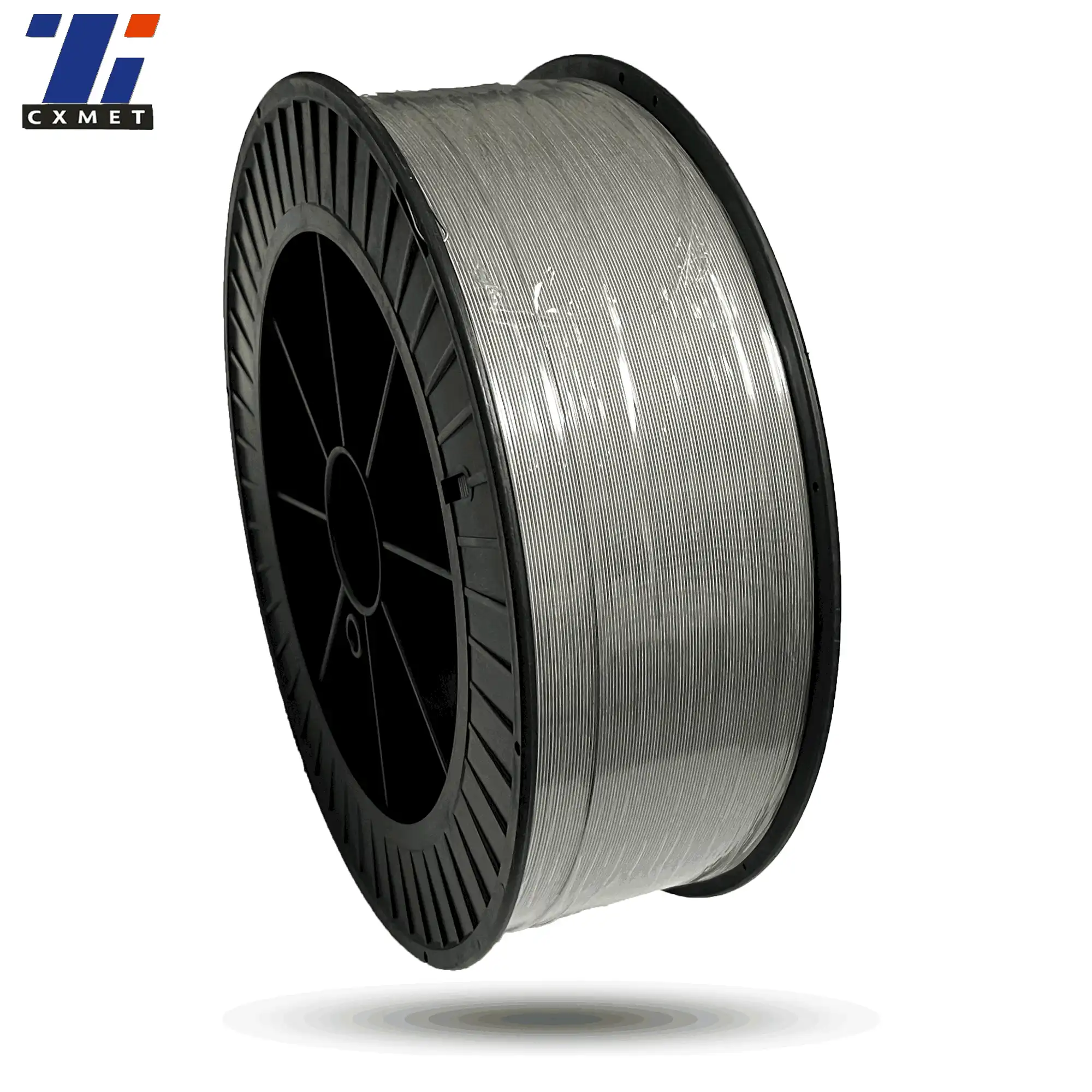

What is Gr1 Titanium Wire?

2024-12-24 10:23:17

Gr1 Titanium Wire, also known as Grade 1 Titanium Wire, is a high-purity titanium alloy that offers exceptional corrosion resistance and biocompatibility. This material is widely used in various industries, including aerospace, medical, and marine applications, due to its unique combination of strength, lightweight properties, and resistance to harsh environments. Gr1 Titanium Wire is composed of commercially pure titanium with minimal impurities, making it an ideal choice for applications requiring the highest level of purity and performance.

What are the properties of Gr1 Titanium Wire?

Gr1 Titanium Wire possesses a remarkable set of properties that make it highly desirable for numerous applications. Its exceptional corrosion resistance is one of its most notable characteristics, allowing it to withstand exposure to various chemicals, saltwater, and other corrosive environments. This property makes it particularly valuable in marine and chemical processing industries where materials are subjected to harsh conditions.

The wire's high strength-to-weight ratio is another key attribute. Despite being incredibly strong, Gr1 Titanium Wire is significantly lighter than many other metals, including steel. This combination of strength and lightness makes it an excellent choice for aerospace and automotive applications where weight reduction is crucial for improved fuel efficiency and performance.

Biocompatibility is another essential property of Gr1 Titanium Wire. The human body readily accepts titanium, making it an ideal material for medical implants, surgical instruments, and other medical devices. This biocompatibility, coupled with its corrosion resistance, ensures that Gr1 Titanium Wire can be safely used in long-term medical applications without causing adverse reactions or degradation.

The wire also exhibits excellent heat transfer properties and a low coefficient of thermal expansion. These characteristics make it suitable for heat exchangers and other applications where thermal management is critical. Additionally, Gr1 Titanium Wire has good electrical conductivity, although not as high as copper or aluminum, making it useful in certain electrical applications where corrosion resistance is a priority.

Another notable property of Gr1 Titanium Wire is its ability to form a protective oxide layer when exposed to oxygen. This naturally occurring layer enhances the wire's corrosion resistance and helps maintain its integrity in various environments. The wire also demonstrates good fatigue resistance, allowing it to withstand repeated stress cycles without failure, which is particularly important in applications subject to cyclic loading.

How is Gr1 Titanium Wire manufactured?

The manufacturing process of Gr1 Titanium Wire involves several complex steps to ensure the highest quality and purity of the final product. The process begins with the extraction of titanium from its ore, typically ilmenite or rutile. This is done through a series of chemical reactions known as the Kroll process, which involves reducing titanium tetrachloride with magnesium to produce pure titanium sponge.

Once the titanium sponge is obtained, it undergoes a melting process in a vacuum or inert gas environment to prevent contamination. The molten titanium is then cast into ingots, which serve as the starting material for wire production. These ingots are carefully inspected for any defects or impurities before proceeding to the next stage.

The titanium ingots are then subjected to a series of hot working processes, including forging and rolling, to break down the cast structure and improve the material's mechanical properties. This step is crucial in achieving the desired grain structure and enhancing the wire's overall strength and ductility.

After hot working, the titanium is drawn into wire through a process called wire drawing. This involves pulling the material through a series of progressively smaller dies to reduce its diameter and increase its length. The wire drawing process is typically performed at room temperature and may require multiple passes to achieve the desired wire diameter.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the wire meets the required specifications for Gr1 Titanium. This includes regular testing for chemical composition, mechanical properties, and dimensional accuracy. Heat treatments may also be applied at various stages to optimize the wire's properties and relieve internal stresses.

The final steps in the manufacturing process involve cleaning, straightening, and packaging the wire. Surface treatments may be applied to enhance specific properties or improve the wire's appearance. The finished Gr1 Titanium Wire is then carefully packaged to protect it from damage during transportation and storage.

What are the applications of Gr1 Titanium Wire?

Gr1 Titanium Wire finds applications across a wide range of industries due to its unique combination of properties. In the aerospace industry, it is used in the construction of aircraft components, particularly in areas where corrosion resistance and high strength-to-weight ratio are critical. The wire may be used in fasteners, springs, and other small parts that require excellent fatigue resistance and durability in harsh environments.

The medical field is another significant area of application for Gr1 Titanium Wire. Its biocompatibility makes it ideal for use in various medical devices and implants. For example, the wire is commonly used in orthodontic applications, such as braces and archwires, where its strength and flexibility are advantageous. It is also used in the production of surgical sutures, stents, and other implantable devices that require long-term stability within the human body.

In the marine industry, Gr1 Titanium Wire is prized for its exceptional corrosion resistance to saltwater and marine environments. It is used in various applications, including offshore oil and gas extraction equipment, underwater sensors, and marine research instruments. The wire's ability to withstand prolonged exposure to seawater without degradation makes it an excellent choice for these demanding applications.

The chemical processing industry also benefits from the use of Gr1 Titanium Wire. Its resistance to a wide range of chemicals makes it suitable for use in heat exchangers, pumps, and other equipment exposed to corrosive substances. The wire's ability to maintain its integrity in these harsh environments helps to extend the lifespan of critical components and reduce maintenance costs.

In the field of energy production, Gr1 Titanium Wire plays a role in various applications. It is used in the construction of heat exchangers for power plants, particularly in geothermal energy systems where corrosion resistance is crucial. The wire may also be employed in the manufacture of components for fuel cells and other alternative energy technologies.

The automotive industry is another sector where Gr1 Titanium Wire finds applications, particularly in high-performance and racing vehicles. Its high strength-to-weight ratio makes it ideal for use in suspension components, valve springs, and other parts where weight reduction and durability are essential.

In conclusion, Gr1 Titanium Wire is a versatile material with a wide range of applications across multiple industries. Its unique combination of properties, including corrosion resistance, high strength-to-weight ratio, and biocompatibility, make it an invaluable material in modern engineering and manufacturing. As technology continues to advance, it is likely that new applications for this remarkable material will continue to emerge, further solidifying its importance in various fields.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

- ASTM International. (2021). Standard Specification for Titanium and Titanium Alloy Wire.

- Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

- Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

- Boyer, R. R. (1996). An overview on the use of titanium in the aerospace industry. Materials Science and Engineering: A, 213(1-2), 103-114.

- Schutz, R. W., & Watkins, H. B. (1998). Recent developments in titanium alloy application in the energy industry. Materials Science and Engineering: A, 243(1-2), 305-315.

- Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 1(1), 30-42.

- Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.

- Faller, K., & Froes, F. H. (2001). The use of titanium in family automobiles: Current trends. JOM, 53(4), 27-28.