- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

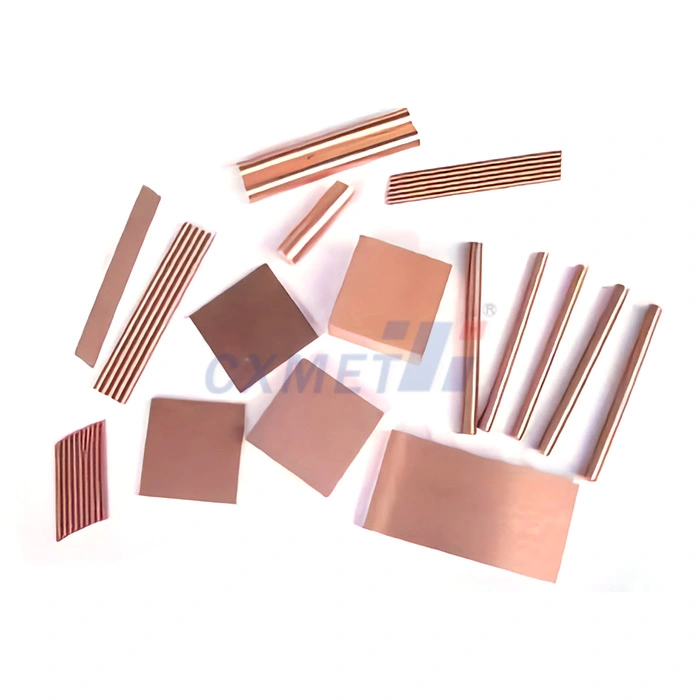

What is GR2 Titanium Wire?

GR2 Titanium Wire is a high-quality, pure form of titanium wire known for its exceptional strength, corrosion resistance, and biocompatibility. Grade 2 (GR2) titanium is one of the most commonly used grades of commercially pure titanium, offering an excellent balance of mechanical properties and affordability. This versatile material finds applications in various industries, including aerospace, medical, marine, and jewelry making.

What are the properties of GR2 Titanium Wire?

GR2 Titanium Wire possesses a unique combination of properties that make it highly desirable for numerous applications. Its most notable characteristics include:

1. Exceptional strength-to-weight ratio: GR2 Titanium Wire is remarkably strong for its weight, offering a tensile strength of approximately 345 MPa (50,000 psi) while remaining lightweight. This property makes it ideal for applications where weight reduction is crucial, such as in aerospace and automotive industries.

2. Excellent corrosion resistance: Titanium naturally forms a protective oxide layer on its surface when exposed to air or moisture. This layer provides outstanding resistance to corrosion from various substances, including saltwater, acids, and industrial chemicals. As a result, GR2 Titanium Wire is widely used in marine environments and chemical processing equipment.

3. Biocompatibility: GR2 Titanium is highly biocompatible, meaning it is non-toxic and well-tolerated by the human body. This property makes it an excellent choice for medical implants, surgical instruments, and dental applications.

4. Low thermal expansion: The wire exhibits a low coefficient of thermal expansion, which means it maintains its dimensional stability across a wide range of temperatures. This property is particularly valuable in precision engineering and aerospace applications.

5. Non-magnetic properties: GR2 Titanium Wire is non-magnetic, making it suitable for use in applications where magnetic interference must be avoided, such as in certain medical devices and scientific instruments.

6. Workability: Despite its strength, GR2 Titanium Wire is relatively easy to work with. It can be formed, machined, and welded using various techniques, allowing for versatility in manufacturing processes.

7. High melting point: With a melting point of approximately 1,660°C (3,020°F), GR2 Titanium Wire maintains its structural integrity at high temperatures, making it suitable for use in high-temperature environments.

These properties contribute to the wide-ranging applications of GR2 Titanium Wire across various industries, from aerospace and automotive to medical and jewelry making.

How is GR2 Titanium Wire manufactured?

The manufacturing process of GR2 Titanium Wire involves several steps to ensure the production of high-quality, consistent wire with the desired properties. Here's an overview of the typical manufacturing process:

1. Raw material preparation: The process begins with high-purity titanium sponge, which is produced through the Kroll process. This sponge is then melted and alloyed with trace elements to achieve the specific composition required for Grade 2 titanium.

2. Ingot formation: The molten titanium is cast into large ingots, which are then allowed to cool and solidify. These ingots serve as the starting material for the wire drawing process.

3. Hot working: The titanium ingots undergo hot working processes such as forging or rolling to break down the cast structure and improve the material's mechanical properties. This step also helps to reduce the ingot's cross-sectional area.

4. Annealing: The hot-worked material is then annealed to relieve internal stresses and improve ductility. This heat treatment process involves heating the titanium to a specific temperature and then cooling it slowly, which helps to optimize its microstructure.

5. Cold drawing: The annealed titanium is then drawn through a series of progressively smaller dies to reduce its diameter and increase its length. This cold-working process significantly improves the material's strength and hardness while also achieving the desired wire diameter.

6. Intermediate annealing: Depending on the final wire specifications, intermediate annealing steps may be performed between cold drawing stages to restore ductility and prevent excessive work hardening.

7. Surface treatment: The drawn wire may undergo surface treatments such as pickling or electropolishing to remove any surface impurities or oxides and improve its appearance and performance.

8. Final heat treatment: A final heat treatment may be applied to achieve the desired combination of strength and ductility in the finished wire.

9. Quality control: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the wire meets the required specifications for chemical composition, mechanical properties, and dimensional accuracy.

10. Packaging and labeling: The finished GR2 Titanium Wire is carefully packaged to protect it from damage and contamination during storage and transportation. Proper labeling ensures traceability and provides important information about the wire's specifications.

The manufacturing process of GR2 Titanium Wire requires specialized equipment and expertise to handle the unique challenges posed by titanium's properties. Factors such as precise temperature control during heat treatments, prevention of contamination, and careful control of the cold drawing process are critical to producing high-quality wire that meets industry standards.

Continuous advancements in manufacturing technologies and processes have led to improvements in the quality and consistency of GR2 Titanium Wire production. These developments have expanded the range of available wire diameters and surface finishes, further increasing the versatility of this material in various applications.

What are the applications of GR2 Titanium Wire?

GR2 Titanium Wire finds applications across a wide range of industries due to its unique combination of properties. Here are some of the key areas where this versatile material is utilized:

1. Aerospace industry: In aerospace applications, GR2 Titanium Wire is used for various purposes, including:

- Fasteners and bolts for aircraft structures

- Springs and clips in aircraft systems

- Reinforcement in composite materials

- Wire mesh for sound attenuation in engines

The wire's high strength-to-weight ratio and excellent corrosion resistance make it ideal for reducing aircraft weight while maintaining structural integrity.

2. Medical and dental applications: The biocompatibility of GR2 Titanium Wire makes it an excellent choice for medical and dental uses, such as:

- Orthopedic implants and surgical staples

- Dental implants and orthodontic wires

- Surgical instruments and needles

- Frames for medical devices and equipment

Its non-toxic nature and resistance to bodily fluids ensure long-term stability and patient safety.

3. Marine industry: The corrosion resistance of GR2 Titanium Wire is particularly valuable in marine environments. Applications include:

- Rigging and cable systems for boats and ships

- Fasteners and fittings for marine structures

- Anodes for cathodic protection systems

- Components in desalination plants

4. Chemical processing: In chemical processing industries, GR2 Titanium Wire is used for:

- Heat exchangers and condensers

- Filters and screens

- Electrode baskets for electroplating

- Corrosion-resistant fasteners and springs

Its resistance to a wide range of chemicals makes it suitable for use in aggressive environments.

5. Jewelry making: GR2 Titanium Wire is popular in the jewelry industry due to its hypoallergenic properties and aesthetic appeal. It is used for:

- Earrings and body piercing jewelry

- Necklaces and bracelets

- Decorative wire wrapping

- Custom jewelry designs

6. Automotive industry: In automotive applications, GR2 Titanium Wire is used for:

- Valve springs in high-performance engines

- Exhaust system components

- Suspension springs

- Reinforcement in composite materials

7. Sports equipment: The lightweight and strong properties of GR2 Titanium Wire make it suitable for various sports equipment, including:

- Bicycle spokes and frames

- Golf club shafts

- Tennis racket strings

- Fishing line and lures

8. Energy sector: In the energy industry, GR2 Titanium Wire finds applications in:

- Heat exchangers for power plants

- Geothermal well casings

- Components in offshore oil and gas platforms

- Solar panel frames and support structures

9. Artistic and decorative uses: Artists and designers use GR2 Titanium Wire for:

- Sculptures and installations

- Decorative meshes and screens

- Architectural elements

- Custom lighting fixtures

10. Research and development: GR2 Titanium Wire is often used in research settings for:

- Material testing and characterization

- Prototype development

- Specialized scientific instruments

- Experimental sensors and probes

The versatility of GR2 Titanium Wire continues to drive innovation across these industries, with new applications emerging as researchers and engineers explore its potential. Its unique combination of properties makes it an invaluable material in situations where strength, lightness, corrosion resistance, and biocompatibility are crucial factors.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM International. (2021). ASTM B863-14 Standard Specification for Titanium and Titanium Alloy Wire.

2. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

3. Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

4. Froes, F. H. (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

5. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons.

6. Lütjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

7. Matthew, I. G., & Donachie, J. (2000). Titanium: A Technical Guide. ASM International.

8. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

9. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

10. Schutz, R. W., & Watkins, H. B. (1998). Recent developments in titanium alloy application in the energy industry. Materials Science and Engineering: A, 243(1-2), 305-315.