- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

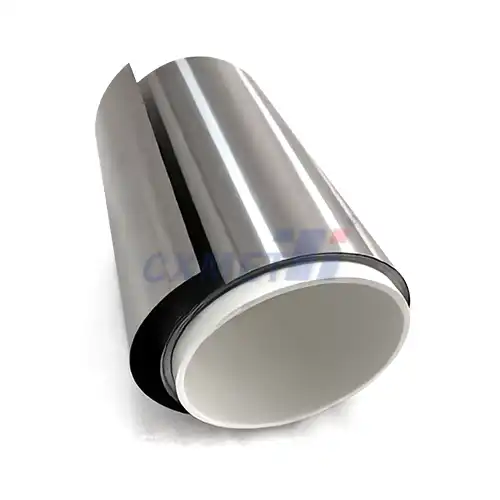

What is the Composition of GR2 Titanium Seamless Tube?

2024-09-09 15:25:48

Grade 2 (GR2) Titanium Seamless Tube is a high-performance material widely used in various industries due to its exceptional properties. The composition of GR2 Titanium is primarily pure titanium with minimal alloying elements. Specifically, GR2 Titanium consists of 99.2% titanium and small amounts of other elements such as iron, carbon, nitrogen, oxygen, and hydrogen. This composition gives GR2 Titanium Seamless Tubes their unique characteristics, including excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility.

How does GR2 Titanium compare to other grades of titanium?

When comparing GR2 Titanium to other grades of titanium, it's essential to understand the different classifications and their properties. Titanium grades are divided into several categories, with GR2 falling under the commercially pure (CP) titanium group.

GR2 Titanium is often compared to other commercially pure grades like GR1, GR3, and GR4. The main differences lie in the amount of oxygen and iron content, which affects the strength and ductility of the material. GR2 Titanium offers a balance between strength and formability, making it a versatile choice for many applications.

Compared to GR1 Titanium, GR2 has slightly higher strength due to its increased oxygen content. This makes GR2 suitable for applications that require more strength than GR1 can provide while still maintaining excellent corrosion resistance and formability. GR3 and GR4 Titanium, on the other hand, have progressively higher strength levels but decreased ductility compared to GR2.

When comparing GR2 Titanium to alloyed grades like Ti-6Al-4V (Grade 5), the differences become more pronounced. Alloyed grades generally offer higher strength and better high-temperature performance but may have reduced corrosion resistance and biocompatibility compared to GR2 Titanium.

The choice between GR2 Titanium and other grades depends on the specific application requirements. GR2 Titanium Seamless Tubes are often preferred in chemical processing, marine environments, and medical implants due to their excellent corrosion resistance and biocompatibility. In contrast, aerospace and automotive industries might opt for higher-strength alloyed grades for structural components.

It's worth noting that GR2 Titanium's composition allows for easier welding and forming compared to higher-strength grades, making it a popular choice for fabricating complex shapes and structures. This characteristic, combined with its corrosion resistance, makes GR2 Titanium Seamless Tubes an excellent choice for heat exchangers, condensers, and other applications involving aggressive environments.

What are the key properties and applications of GR2 Titanium Seamless Tubes?

GR2 Titanium Seamless Tubes possess a unique combination of properties that make them suitable for a wide range of applications across various industries. Understanding these properties is crucial for engineers and designers when selecting materials for specific projects.

One of the most notable properties of GR2 Titanium Seamless Tubes is their exceptional corrosion resistance. The material forms a stable, continuous, tightly adherent oxide film on its surface when exposed to oxygen, providing protection against corrosive environments. This characteristic makes GR2 Titanium Seamless Tubes ideal for use in chemical processing plants, desalination facilities, and marine applications where exposure to harsh chemicals or saltwater is common.

Another key property is the high strength-to-weight ratio of GR2 Titanium. While not as strong as some alloyed grades, GR2 Titanium still offers impressive strength considering its low density. This property makes it an excellent choice for applications where weight reduction is crucial, such as in the aerospace and automotive industries.

GR2 Titanium Seamless Tubes also exhibit excellent biocompatibility, making them a preferred material in the medical and dental fields. The human body readily accepts titanium, and it does not cause allergic reactions or rejections, unlike some other metals. This property has led to the widespread use of GR2 Titanium in surgical implants, dental implants, and other medical devices.

The material's low thermal expansion coefficient is another valuable property, especially in applications involving temperature fluctuations. This characteristic ensures dimensional stability across a wide range of temperatures, making GR2 Titanium Seamless Tubes suitable for heat exchangers and condensers in various industrial processes.

Furthermore, GR2 Titanium has good fatigue strength and crack resistance, contributing to the long-term reliability of components made from this material. This property is particularly important in applications involving cyclic loading or stress, such as in the oil and gas industry for downhole tools and offshore platforms.

The applications of GR2 Titanium Seamless Tubes are diverse and span multiple industries. In the chemical processing industry, these tubes are used for piping systems, reactors, and storage tanks handling corrosive chemicals. The marine industry utilizes GR2 Titanium for heat exchangers, condensers, and desalination equipment due to its excellent resistance to saltwater corrosion.

In the medical field, GR2 Titanium Seamless Tubes find applications in surgical instruments, implants, and prosthetics. The material's biocompatibility and strength make it an ideal choice for long-term implants such as hip replacements and dental implants.

The aerospace industry benefits from the high strength-to-weight ratio of GR2 Titanium Seamless Tubes, using them in hydraulic systems, fuel lines, and structural components of aircraft. Similarly, the automotive sector employs these tubes in exhaust systems, suspension components, and other areas where corrosion resistance and weight reduction are crucial.

Energy production is another field where GR2 Titanium Seamless Tubes play a significant role. In power plants, these tubes are used in condensers, heat exchangers, and other components exposed to high temperatures and corrosive environments. The material's resistance to erosion and cavitation makes it suitable for use in hydroelectric turbines and other water-handling equipment.

How is GR2 Titanium Seamless Tube manufactured?

The manufacturing process of GR2 Titanium Seamless Tubes is a complex and highly controlled procedure that ensures the final product meets the required specifications and quality standards. Understanding this process is essential for appreciating the material's properties and ensuring its proper application in various industries.

The production of GR2 Titanium Seamless Tubes begins with the creation of titanium sponge, which is the raw material for titanium production. This sponge is produced through the Kroll process, where titanium tetrachloride is reduced with magnesium to form pure titanium. The resulting titanium sponge is then melted and cast into ingots or billets.

Once the titanium ingots are prepared, they undergo a series of forming processes to create the seamless tubes. The primary methods used for producing seamless tubes are extrusion and pilgering.

In the extrusion process, the titanium billet is heated to a high temperature, typically around 800-900°C, to increase its malleability. The heated billet is then forced through a die using a powerful hydraulic press. This process creates a hollow tube with a relatively large diameter and wall thickness.

Following extrusion, the tubes often undergo a cold working process called pilgering. This technique involves passing the tube through a set of grooved rolls that progressively reduce the diameter and wall thickness of the tube while increasing its length. Pilgering is performed in multiple passes, with intermediate annealing steps to relieve internal stresses and maintain the material's ductility.

Throughout the manufacturing process, strict control of temperature, pressure, and deformation rates is crucial to maintain the desired microstructure and properties of the GR2 Titanium. The seamless nature of these tubes is particularly important as it eliminates the weak points and potential failure sites associated with welded seams.

After the forming processes, the tubes undergo heat treatment to achieve the desired mechanical properties and relieve any residual stresses from the forming operations. This heat treatment typically involves annealing, where the tubes are heated to a specific temperature and then cooled slowly to room temperature.

The final steps in the manufacturing process involve surface treatments and quality control. The tubes may undergo pickling to remove any surface oxides formed during the heat treatment process. This is followed by thorough inspections, including dimensional checks, non-destructive testing (such as ultrasonic or eddy current testing), and mechanical property testing to ensure the tubes meet the required specifications.

The manufacturing process of GR2 Titanium Seamless Tubes is designed to produce a high-quality product with consistent properties throughout its length. This consistency is crucial for applications in industries such as aerospace, chemical processing, and medical implants, where reliability and performance are paramount.

It's worth noting that the manufacturing process can be tailored to produce tubes with specific dimensions and properties to suit particular applications. This flexibility, combined with the inherent properties of GR2 Titanium, contributes to the material's widespread use across various industries.

In conclusion, GR2 Titanium Seamless Tubes are a remarkable material with a unique composition that provides an excellent balance of properties. Their corrosion resistance, strength-to-weight ratio, and biocompatibility make them invaluable in numerous applications across diverse industries. The careful manufacturing process ensures the production of high-quality tubes that meet the demanding requirements of modern engineering and medical applications. As technology advances, we can expect to see continued innovation in the production and application of GR2 Titanium Seamless Tubes, further expanding their role in shaping our technological landscape.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM International. (2021). ASTM B338 - Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers.

2. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

3. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

4. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

5. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH.

6. Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. (2003). Structure and Properties of Titanium and Titanium Alloys. In Titanium and Titanium Alloys (pp. 1-36). Wiley-VCH.

7. Froes, F. H. (Ed.). (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

8. Banerjee, D., & Williams, J. C. (2013). Perspectives on Titanium Science and Technology. Acta Materialia, 61(3), 844-879.

9. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

10. Polmear, I., StJohn, D., Nie, J. F., & Qian, M. (2017). Light Alloys: Metallurgy of the Light Metals (5th ed.). Butterworth-Heinemann.