- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Composition of TM0157 Titanium Wire?

2025-01-22 10:46:51

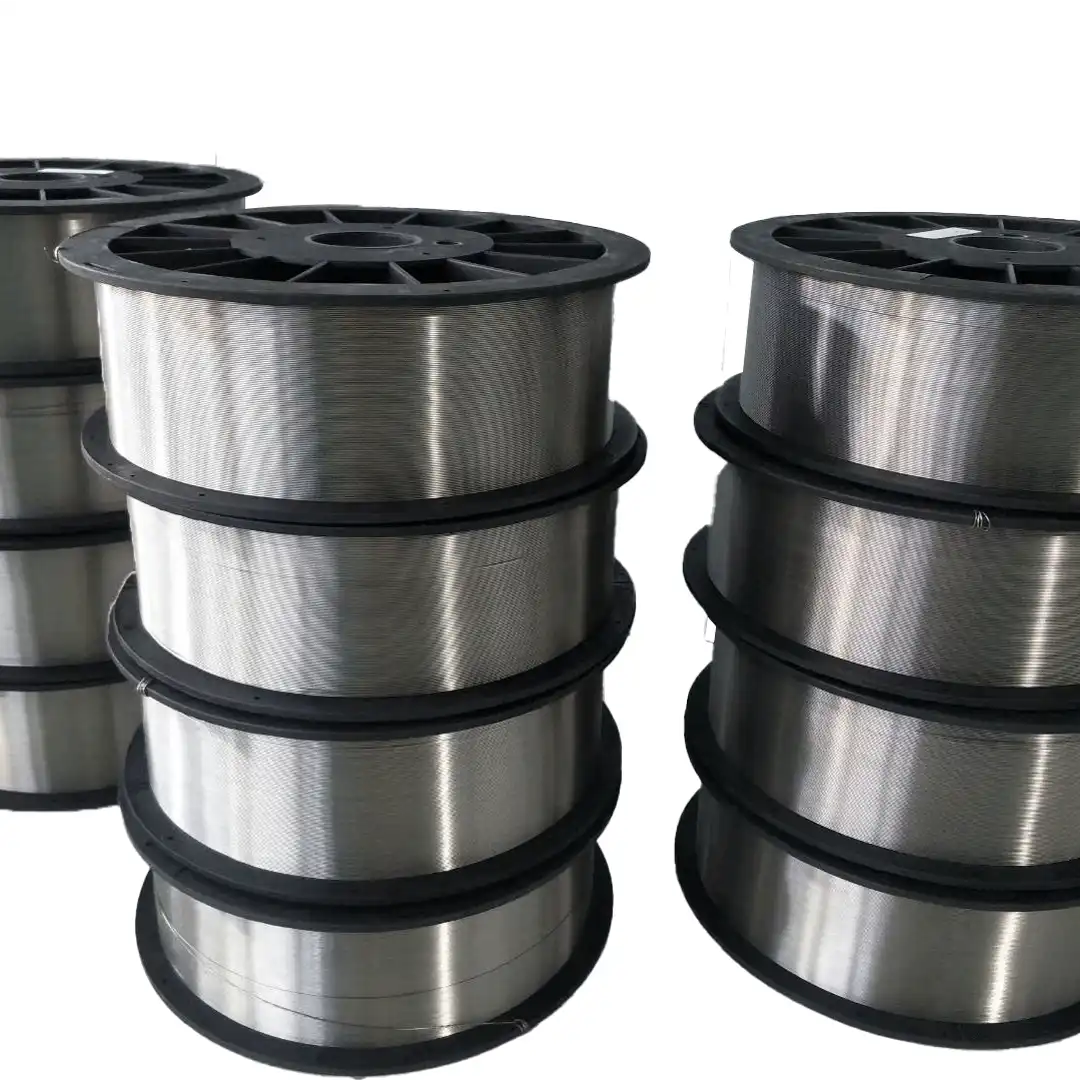

TM0157 titanium wire is a specialized alloy known for its unique composition and exceptional properties. This high-performance material is widely used in various industries, including aerospace, medical, and automotive sectors. Understanding the composition of TM0157 titanium wire is crucial for engineers and manufacturers who rely on its specific characteristics for their applications.

What are the key alloying elements in TM0157 titanium wire?

TM0157 titanium wire is primarily composed of titanium, which forms the base of this alloy. However, its exceptional properties are derived from the careful addition of specific alloying elements. The key alloying elements in TM0157 titanium wire include:

- Aluminum (Al): Typically present in a range of 5.5-6.75% by weight, aluminum enhances the strength-to-weight ratio and improves oxidation resistance.

- Vanadium (V): Added in a range of 3.5-4.5% by weight, vanadium contributes to increased strength and helps maintain a stable microstructure.

- Iron (Fe): Present in small amounts, usually less than 0.3% by weight, iron helps control grain size and improves strength.

- Oxygen (O): Controlled to be less than 0.2% by weight, oxygen affects the mechanical properties and must be carefully managed.

The precise balance of these alloying elements is critical to achieving the desired properties of TM0157 titanium wire. The composition is carefully controlled during the manufacturing process to ensure consistency and reliability in performance.

In addition to these primary alloying elements, TM0157 may contain trace amounts of other elements such as carbon, nitrogen, and hydrogen. These elements are typically present in very small quantities but can still influence the overall properties of the alloy.

The unique composition of TM0157 titanium wire results in a material that offers an excellent combination of strength, ductility, and corrosion resistance. This makes it particularly suitable for applications requiring high performance under demanding conditions, such as in aerospace components or medical implants.

How does the composition affect the properties of TM0157 titanium wire?

The composition of TM0157 titanium wire directly influences its mechanical, physical, and chemical properties. Each alloying element plays a specific role in determining the overall characteristics of the material:

- Strength: The addition of aluminum and vanadium significantly enhances the strength of TM0157 titanium wire. These elements form intermetallic compounds within the titanium matrix, which act as obstacles to dislocation movement, thereby increasing the alloy's yield strength and tensile strength.

- Ductility: While the alloying elements improve strength, they also affect the ductility of the material. The careful balance of elements in TM0157 ensures that it maintains good ductility, allowing it to be formed into various shapes without fracturing.

- Corrosion Resistance: Titanium naturally forms a protective oxide layer, and the addition of aluminum further enhances this property. The aluminum in TM0157 helps create a more stable and adherent oxide film, improving the alloy's resistance to various corrosive environments.

- Temperature Resistance: The composition of TM0157 allows it to maintain its strength and stability at elevated temperatures. This is particularly important for aerospace applications where materials must perform reliably under high-temperature conditions.

- Density: The addition of aluminum, which is lighter than titanium, helps to keep the overall density of TM0157 relatively low. This contributes to its high strength-to-weight ratio, making it an ideal choice for weight-sensitive applications.

The precise control of oxygen content in TM0157 is crucial, as oxygen can have both beneficial and detrimental effects. While a small amount of oxygen can contribute to strength, excessive oxygen can lead to embrittlement and reduced ductility.

The iron content in TM0157, although small, plays a role in controlling the grain structure of the alloy. This helps in achieving a fine-grained microstructure, which contributes to improved mechanical properties and better formability of the wire.

Understanding how the composition affects these properties is essential for engineers and designers when selecting materials for specific applications. The unique balance of elements in TM0157 titanium wire allows it to offer a combination of properties that make it suitable for a wide range of demanding applications across various industries.

What are the manufacturing processes used to produce TM0157 titanium wire?

The production of TM0157 titanium wire involves a series of sophisticated manufacturing processes that ensure the precise composition and desired properties of the final product. These processes are carefully controlled to maintain the integrity of the alloy and achieve the required specifications. The main steps in manufacturing TM0157 titanium wire include:

- Raw Material Preparation: High-purity titanium sponge is combined with the alloying elements (aluminum, vanadium, and others) in precise proportions. The quality and purity of these raw materials are crucial for the final properties of the wire.

- Melting and Ingot Formation: The raw material mixture is melted in a vacuum or controlled atmosphere furnace to prevent contamination. Multiple melting cycles may be used to ensure homogeneity. The molten metal is then cast into ingots.

- Primary Processing: The ingots undergo primary processing, which may include forging, rolling, or extrusion. This step helps to break down the as-cast structure and improve the overall properties of the material.

- Heat Treatment: The processed material undergoes heat treatment to achieve the desired microstructure and properties. This may include solution treatment and aging processes.

- Wire Drawing: The heat-treated material is drawn into wire through a series of dies with progressively smaller diameters. This process aligns the grain structure and increases the strength of the wire.

- Intermediate Annealing: Between drawing stages, the wire may be annealed to relieve internal stresses and maintain ductility for further processing.

- Surface Treatment: The wire may undergo surface treatments such as pickling or polishing to remove any oxide layers and improve surface finish.

- Final Inspection and Testing: The finished wire is subjected to rigorous quality control measures, including dimensional checks, mechanical testing, and compositional analysis to ensure it meets the required specifications.

Throughout these processes, strict control of temperature, atmosphere, and processing parameters is maintained to ensure the desired composition and properties of TM0157 titanium wire. Advanced techniques such as vacuum arc remelting (VAR) or electron beam melting (EBM) may be employed to achieve exceptionally high purity and consistent composition.

The manufacturing of TM0157 titanium wire also involves careful consideration of the wire's intended application. For instance, wire destined for aerospace use may undergo additional quality assurance steps and certifications compared to wire for general industrial applications.

Advancements in manufacturing technologies have led to improvements in the production of TM0157 titanium wire. For example, the use of plasma arc melting (PAM) has enabled better control over the melting process, resulting in more consistent alloy composition and reduced impurities.

The complexity of these manufacturing processes underscores the importance of working with reputable suppliers who have the expertise and equipment necessary to produce high-quality TM0157 titanium wire consistently. The ability to maintain tight compositional control and achieve the required mechanical properties is crucial for the performance and reliability of components made from this specialized alloy.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

- ASM International. (2015). Titanium: Physical Metallurgy, Processing, and Applications.

- Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

- Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium Alloys for Aerospace Applications. Advanced Engineering Materials, 5(6), 419-427.

- Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

- Froes, F. H. (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

- Banerjee, D., & Williams, J. C. (2013). Perspectives on Titanium Science and Technology. Acta Materialia, 61(3), 844-879.

- Leyens, C., & Peters, M. (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH.

- Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

YOU MAY LIKE