- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Difference Between GR3 and Other Titanium Grades?

2024-09-09 15:17:10

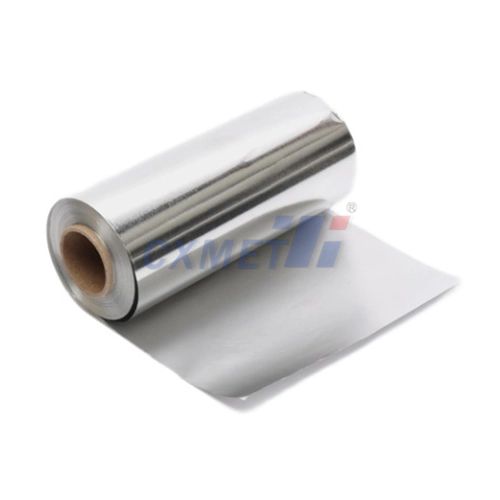

Titanium and its alloys have become increasingly popular in various industries due to their exceptional properties, including high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Among the different grades of titanium, Grade 3 (GR3) stands out for its unique characteristics and applications. This blog post will explore the differences between GR3 and other titanium grades, focusing on GR3 titanium seamless tubes and their properties, corrosion resistance, and applications.

What are the key properties of GR3 titanium seamless tubes?

GR3 titanium, also known as commercially pure (CP) titanium grade 3, is one of the unalloyed titanium grades. It offers a balance of strength and ductility, making it an excellent choice for various applications. GR3 titanium seamless tubes possess several key properties that set them apart from other titanium grades:

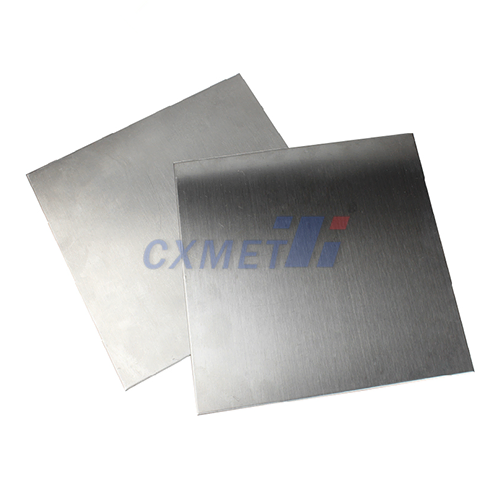

1. Strength and Ductility: GR3 titanium has a higher strength than grades 1 and 2 while maintaining good ductility. This combination makes it suitable for applications requiring moderate strength and excellent formability. The typical tensile strength of GR3 titanium ranges from 450 to 590 MPa, with a minimum yield strength of 380 MPa.

2. Low Density: Like other titanium grades, GR3 has a relatively low density of approximately 4.51 g/cm³. This low density contributes to its high strength-to-weight ratio, making it an ideal material for weight-sensitive applications in aerospace, marine, and chemical processing industries.

3. Excellent Weldability: GR3 titanium seamless tubes exhibit excellent weldability, allowing for easy joining and fabrication. This property is crucial in industries where complex structures or assemblies are required, such as in chemical processing plants or heat exchangers.

4. High Melting Point: With a melting point of around 1668°C (3034°F), GR3 titanium maintains its structural integrity at elevated temperatures. This characteristic makes it suitable for high-temperature applications in various industrial settings.

5. Low Thermal Expansion: GR3 titanium has a low coefficient of thermal expansion, approximately 8.6 × 10^-6 m/(m·K) at 20°C. This property ensures dimensional stability in applications involving temperature fluctuations, making it ideal for use in heat exchangers and other thermal management systems.

6. Biocompatibility: Like other commercially pure titanium grades, GR3 is highly biocompatible. This property makes it suitable for medical and dental applications, including surgical implants and prosthetics.

7. Excellent Fatigue Resistance: GR3 titanium seamless tubes demonstrate superior fatigue resistance compared to many other metals. This property is crucial in applications involving cyclic loading, such as in aerospace components or industrial machinery.

These key properties of GR3 titanium seamless tubes contribute to their versatility and wide range of applications across various industries. The combination of strength, ductility, and corrosion resistance makes GR3 an attractive option for engineers and designers seeking high-performance materials for demanding environments.

How does GR3 titanium compare to other grades in corrosion resistance?

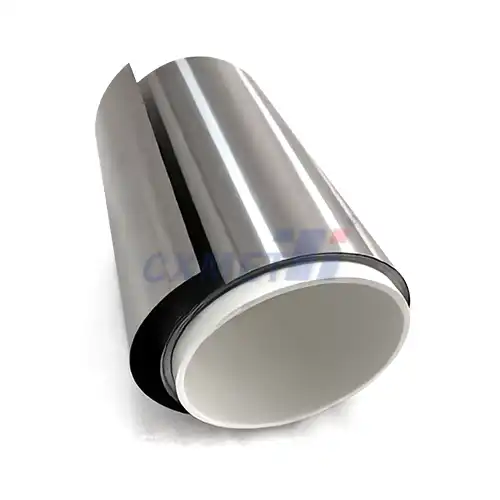

One of the most significant advantages of titanium and its alloys is their exceptional corrosion resistance. GR3 titanium, in particular, exhibits excellent corrosion resistance in various environments, making it a preferred choice for many industrial applications. Let's compare GR3 titanium's corrosion resistance to other titanium grades:

1. General Corrosion Resistance: GR3 titanium, like other commercially pure titanium grades, forms a stable, continuous, and highly adherent oxide film on its surface when exposed to air or moisture. This passive film provides excellent protection against general corrosion in various environments, including seawater, oxidizing acids, and chlorine compounds.

2. Comparison with Lower Grades (GR1 and GR2): GR3 titanium offers slightly better corrosion resistance than Grade 1 and Grade 2 titanium in most environments. This improvement is due to the slightly higher iron and oxygen content in GR3, which enhances the stability of the passive oxide layer.

3. Performance in Reducing Acids: While GR3 titanium performs exceptionally well in oxidizing environments, it may be less resistant to reducing acids compared to some higher-grade titanium alloys. For instance, Grade 7 or Grade 12 titanium, which contain small amounts of palladium or molybdenum, respectively, offer better resistance to reducing acids like hydrochloric acid.

4. Crevice Corrosion Resistance: GR3 titanium exhibits good resistance to crevice corrosion, particularly in chloride-containing environments. However, some higher-grade titanium alloys, such as Grade 7 or Grade 11, may offer superior resistance to crevice corrosion in extremely aggressive environments.

5. Stress Corrosion Cracking (SCC) Resistance: GR3 titanium demonstrates excellent resistance to stress corrosion cracking in most environments. It outperforms many other metals and alloys in this aspect, making it suitable for applications where SCC is a concern.

6. High-Temperature Corrosion: While GR3 titanium maintains good corrosion resistance at elevated temperatures, some higher-grade titanium alloys, such as Grade 5 (Ti-6Al-4V) or Grade 23 (Ti-6Al-4V ELI), may offer better performance in high-temperature corrosive environments.

7. Galvanic Corrosion: GR3 titanium, like other titanium grades, is highly resistant to galvanic corrosion due to its noble position in the galvanic series. This property makes it compatible with a wide range of other metals and alloys in multi-material assemblies.

8. Hydrogen Embrittlement: GR3 titanium exhibits good resistance to hydrogen embrittlement, which can be a concern in some corrosive environments. However, some higher-grade titanium alloys, particularly those containing palladium or ruthenium (e.g., Grade 7 or Grade 26), offer enhanced protection against hydrogen absorption and embrittlement.

9. Pitting Corrosion: GR3 titanium demonstrates excellent resistance to pitting corrosion in chloride-containing environments. This property is particularly valuable in marine and chemical processing applications where pitting can be a significant concern.

10. Erosion-Corrosion Resistance: While GR3 titanium offers good resistance to erosion-corrosion, some higher-grade titanium alloys with increased hardness and strength may provide better performance in highly erosive environments.

In summary, GR3 titanium offers excellent corrosion resistance in a wide range of environments, outperforming many other metals and alloys. While it may not be the top performer in every corrosive scenario, its overall corrosion resistance, combined with its other favorable properties, makes it a versatile and reliable choice for many industrial applications.

What are the main applications of GR3 titanium seamless tubes?

GR3 titanium seamless tubes find applications in various industries due to their unique combination of properties, including moderate strength, excellent corrosion resistance, and good formability. Here are some of the main applications of GR3 titanium seamless tubes:

1. Chemical Processing Industry:

- Heat exchangers: GR3 titanium tubes are widely used in shell-and-tube heat exchangers, particularly in corrosive environments or when handling aggressive chemicals.

- Reactors: The corrosion resistance of GR3 titanium makes it suitable for reactor vessels and piping in chemical processing plants.

- Distillation columns: Titanium Grade 3 tubes are used in the construction of distillation columns, especially when dealing with corrosive or high-purity products.

2. Oil and Gas Industry:

- Offshore platforms: GR3 titanium tubes are used in various components of offshore platforms due to their excellent resistance to seawater corrosion.

- Desalination plants: The corrosion resistance and heat transfer properties of GR3 titanium make it ideal for use in desalination equipment.

- Downhole tools: Some downhole tools and components in oil and gas extraction may utilize GR3 titanium tubes for their strength and corrosion resistance.

3. Marine Applications:

- Heat exchangers in shipbuilding: GR3 titanium tubes are used in marine heat exchangers due to their excellent resistance to seawater corrosion.

- Propeller shafts: Some marine propeller shafts may be manufactured using GR3 titanium for its corrosion resistance and strength.

- Submarine components: Various components in submarine construction may utilize GR3 titanium tubes for their combination of strength and corrosion resistance.

4. Aerospace Industry:

- Hydraulic systems: GR3 titanium tubes may be used in aircraft hydraulic systems where corrosion resistance and weight savings are crucial.

- Structural components: Some non-critical structural components in aircraft may be fabricated using GR3 titanium tubes.

5. Medical and Dental Applications:

- Surgical implants: GR3 titanium's biocompatibility makes it suitable for certain surgical implants and prosthetics.

- Dental implants: Some dental implants and components may be manufactured using GR3 titanium due to its biocompatibility and corrosion resistance.

6. Power Generation:

- Condenser tubes: GR3 titanium tubes are used in power plant condensers, particularly in applications involving seawater cooling.

- Heat recovery steam generators: The heat transfer properties and corrosion resistance of GR3 titanium make it suitable for use in heat recovery steam generators.

7. Food Processing Industry:

- Heat exchangers: GR3 titanium tubes are used in food-grade heat exchangers due to their corrosion resistance and ease of cleaning.

- Processing equipment: Various food processing equipment may incorporate GR3 titanium tubes, especially when dealing with acidic or corrosive food products.

8. Pulp and Paper Industry:

- Bleaching equipment: The corrosion resistance of GR3 titanium makes it suitable for use in pulp bleaching equipment.

- Heat exchangers: Titanium Grade 3 tubes are used in heat exchangers within pulp and paper mills, particularly when dealing with corrosive chemicals.

9. Automotive Industry:

- Exhaust systems: Some high-performance or luxury vehicles may utilize GR3 titanium tubes in exhaust systems for weight reduction and corrosion resistance.

- Racing applications: GR3 titanium tubes may be used in various components of racing vehicles where weight savings and strength are critical.

10. Environmental Applications:

- Water treatment systems: GR3 titanium tubes are used in water treatment plants, particularly in components exposed to corrosive chemicals or seawater.

- Air pollution control equipment: Some air pollution control devices may incorporate GR3 titanium tubes due to their corrosion resistance and durability.

These applications showcase the versatility of GR3 titanium seamless tubes across various industries. The material's unique combination of properties, including corrosion resistance, strength-to-weight ratio, and biocompatibility, make it an excellent choice for demanding environments and specialized applications.

In conclusion, GR3 titanium offers a balanced set of properties that distinguish it from other titanium grades. Its moderate strength, excellent corrosion resistance, and good formability make it a versatile material for a wide range of applications. While it may not be the top performer in every scenario, GR3 titanium seamless tubes provide a reliable and cost-effective solution for many industrial, marine, and medical applications. As technology advances and new challenges arise, the unique properties of GR3 titanium will continue to make it a valuable material in various fields of engineering and manufacturing.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM International. (2021). ASTM B338 - 21 Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers.

2. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

3. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

4. Schutz, R. W., & Watkins, H. B. (1998). Recent developments in titanium alloy application in the energy industry. Materials Science and Engineering: A, 243(1-2), 305-315.

5. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

6. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

7. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

8. Schutz, R. W. (2005). Corrosion of titanium and titanium alloys. ASM Handbook, 13, 252-299.

9. Yamada, M. (1996). An overview on the development of titanium alloys for non-aerospace application in Japan. Materials Science and Engineering: A, 213(1-2), 8-15.

10. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.