- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

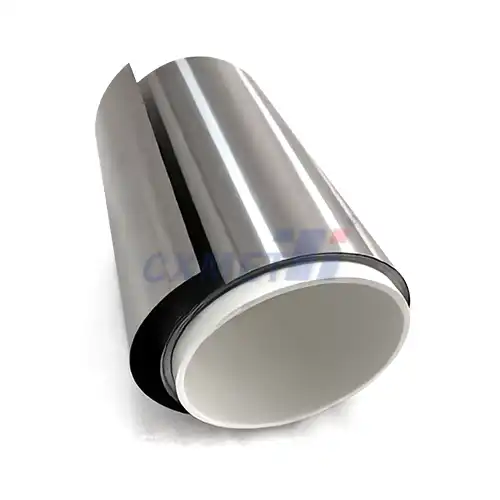

What is Titanium 6Al-4V Grade 5 Sheet?

2024-11-25 13:52:33

Titanium 6Al-4V Grade 5 sheet is a high-performance titanium alloy that has gained widespread recognition in various industries due to its exceptional combination of properties. This alloy is composed of titanium as the base metal, with the addition of 6% aluminum (Al) and 4% vanadium (V), hence the designation "6Al-4V". The "Grade 5" classification indicates that this alloy meets specific mechanical property requirements and has undergone particular heat treatment processes to achieve its desired characteristics.

This alloy stands out among other materials for its remarkable strength-to-weight ratio, excellent corrosion resistance, and exceptional biocompatibility. These properties make it an ideal choice for applications ranging from aerospace and medical implants to industrial equipment and high-performance automotive components.

The development of Titanium 6Al-4V Grade 5 sheet is a result of extensive research and engineering efforts to create a material that can withstand extreme conditions while maintaining its structural integrity. Its unique composition allows it to exhibit a balance of properties that are difficult to achieve with other materials, making it a go-to choice for engineers and designers working on cutting-edge projects.

What Makes Titanium 6Al-4V Grade 5 Sheet Unique?

Titanium 6Al-4V Grade 5 sheet possesses a unique set of characteristics that set it apart from other materials, including other titanium alloys. These properties are the result of its carefully engineered composition and the specific manufacturing processes used to produce it.

1. High Strength-to-Weight Ratio: One of the most notable features of Titanium 6Al-4V Grade 5 sheet is its exceptional strength-to-weight ratio. This alloy boasts a tensile strength that can exceed 900 MPa (130,000 psi) in its annealed condition, while maintaining a relatively low density of about 4.43 g/cm³. This combination makes it significantly stronger than many steels while being nearly 45% lighter. The high strength-to-weight ratio is particularly valuable in aerospace applications, where reducing weight without compromising structural integrity is crucial for improving fuel efficiency and performance.

2. Corrosion Resistance: Titanium 6Al-4V Grade 5 sheet exhibits outstanding corrosion resistance in a wide range of environments. This property is primarily due to the formation of a stable, continuous, highly adherent, and protective oxide film on the metal's surface. This natural oxide layer, primarily composed of titanium dioxide (TiO2), forms instantaneously when fresh metal surfaces are exposed to air or moisture. The alloy's corrosion resistance makes it highly suitable for use in marine environments, chemical processing plants, and other corrosive settings where materials like stainless steel might fail.

3. Biocompatibility: The biocompatibility of Titanium 6Al-4V Grade 5 sheet is one of its most valuable properties, particularly in the medical field. The alloy is non-toxic and not rejected by the body, making it ideal for use in medical implants, prosthetics, and surgical instruments. Its ability to osseointegrate, or form a structural and functional connection with living bone tissue, makes it particularly useful for orthopedic and dental implants. The biocompatibility of this alloy is attributed to the stable oxide layer that forms on its surface, which prevents the release of metal ions into the body.

4. Temperature Resistance: Titanium 6Al-4V Grade 5 sheet maintains its mechanical properties over a wide range of temperatures. It can operate effectively from cryogenic temperatures up to about 800°F (427°C). This temperature resistance makes it particularly valuable in aerospace applications, where components may be subjected to extreme temperature variations. At low temperatures, the alloy does not become brittle, and at elevated temperatures, it retains its strength better than many other aerospace alloys.

5. Fatigue Resistance: The alloy exhibits excellent fatigue resistance, which is crucial for components subjected to repeated stress cycles. This property is particularly important in aerospace and industrial applications where materials must withstand cyclic loading over extended periods without failure.

These unique properties make Titanium 6Al-4V Grade 5 sheet a versatile material that can meet the demanding requirements of various high-performance applications across multiple industries.

How is Titanium 6Al-4V Grade 5 Sheet Manufactured?

The manufacturing process of Titanium 6Al-4V Grade 5 sheet is complex and requires precise control at every stage to ensure the final product meets the required specifications. The process involves several key steps:

1. Melting: The production of Titanium 6Al-4V Grade 5 sheet begins with the melting of raw materials. This is typically done using one of three primary melting methods:

a) Vacuum Arc Remelting (VAR): This process involves melting the raw materials in a vacuum environment using an electric arc. VAR helps remove volatile impurities and ensures a homogeneous composition.

b) Electron Beam Melting (EBM): In this method, a high-energy electron beam is used to melt the raw materials in a vacuum. EBM is known for producing exceptionally clean and homogeneous ingots.

c) Plasma Arc Melting (PAM): This technique uses a plasma torch to melt the raw materials, often in a controlled atmosphere or vacuum. PAM can produce large ingots with good chemical homogeneity.

The choice of melting method depends on the specific requirements of the end product and the manufacturing capabilities available.

2. Ingot Formation: After melting, the molten alloy is cast into large cylindrical ingots. These ingots typically undergo multiple remelting cycles to ensure uniform composition and remove any residual impurities.

3. Primary Processing: The ingots are then subjected to primary processing techniques such as forging or rolling to break down the cast structure and improve the material's mechanical properties. This step often involves:

a) Breakdown forging: The ingot is heated and forged into a more manageable size and shape.

b) Hot rolling: The forged material is rolled at high temperatures to further refine the microstructure and achieve the desired thickness.

4. Heat Treatment: Heat treatment is a crucial step in the manufacturing process of Titanium 6Al-4V Grade 5 sheet. Various heat treatment processes can be applied depending on the desired final properties:

a) Annealing: This process involves heating the material to a specific temperature and then cooling it slowly. Annealing helps relieve internal stresses, increase ductility, and improve machinability.

b) Solution Heat Treatment: The alloy is heated to a temperature above its beta transus (about 1830°F or 999°C) and then rapidly cooled. This process helps achieve a fine, uniform microstructure.

c) Aging: After solution heat treatment, the alloy can be aged at lower temperatures (typically around 900-1100°F or 482-593°C) to precipitate fine particles that increase strength.

d) Stress Relief: This heat treatment is used to relieve residual stresses introduced during manufacturing without significantly affecting the mechanical properties.

5. Final Forming: The heat-treated material undergoes final forming operations to achieve the desired sheet thickness and surface finish. This may involve:

a) Cold rolling: The sheet is rolled at room temperature to achieve precise thickness control and improve surface finish.

b) Stretching: The sheet may be stretched to improve flatness and reduce residual stresses.

c) Leveling: This process ensures the sheet has uniform flatness across its entire surface.

The manufacturing of Titanium 6Al-4V Grade 5 sheet requires significant expertise and specialized equipment. The precise control of each step in the process is crucial to producing a high-quality product that meets the exacting standards required for aerospace, medical, and other critical applications.

What are the Applications of Titanium 6Al-4V Grade 5 Sheet?

Titanium 6Al-4V Grade 5 sheet finds applications across a wide range of industries due to its unique combination of properties. Its versatility makes it a preferred material for many high-performance and critical applications:

1. Aerospace Industry:

The aerospace sector is one of the largest consumers of Titanium 6Al-4V Grade 5 sheet. Its high strength-to-weight ratio and excellent temperature resistance make it ideal for various aircraft components:

- Structural components: Fuselage frames, wing spars, and bulkheads

- Engine components: Fan blades, compressor blades, and discs

- Landing gear components: Struts and actuator cylinders

- Fasteners and fittings

- Hydraulic systems: Tubing and fittings for high-pressure systems

- Space applications: Satellite structures, rocket motor cases, and spacecraft components

2. Medical and Dental Industry:

The biocompatibility of Titanium 6Al-4V Grade 5 makes it an excellent choice for medical applications:

- Orthopedic implants: Hip and knee replacements, bone plates, and screws

- Dental implants and prosthetics

- Cardiovascular devices: Pacemaker cases and artificial heart valves

- Surgical instruments and tools

- Prosthetic limbs and components

3. Chemical Processing Industry:

The corrosion resistance of Titanium 6Al-4V Grade 5 sheet makes it valuable in chemical processing:

- Pressure vessels and reactors

- Heat exchangers and condensers

- Piping systems for corrosive fluids

- Valve components and pump housings

4. Marine Industry:

Its resistance to saltwater corrosion makes it suitable for various marine applications:

- Propeller shafts and propellers

- Hull plates for high-performance boats

- Underwater remotely operated vehicle (ROV) components

- Desalination plant components

5. Automotive Industry:

While not as widely used as in aerospace, Titanium 6Al-4V Grade 5 sheet finds applications in high-performance vehicles:

- Engine components: Valves, connecting rods, and exhaust systems

- Suspension components: Springs and shock absorber parts

- Brake system components

- Racing car body panels and chassis components

The wide range of applications for Titanium 6Al-4V Grade 5 sheet demonstrates its versatility and the value it brings to various industries. As manufacturing techniques continue to improve and new applications are discovered, the use of this alloy is likely to expand further, particularly in areas where its unique properties offer significant advantages over traditional materials.

Conclusion

Titanium 6Al-4V Grade 5 sheet is a remarkable material that continues to play a crucial role in advancing technology across multiple industries. Its unique combination of high strength-to-weight ratio, excellent corrosion resistance, biocompatibility, and temperature resistance makes it an invaluable resource for engineers and designers working on cutting-edge projects.

The complex manufacturing process required to produce Titanium 6Al-4V Grade 5 sheet ensures that the final product meets the exacting standards necessary for its diverse applications. From aerospace and medical implants to chemical processing and high-performance sports equipment, this alloy consistently demonstrates its versatility and reliability.

As research continues and manufacturing processes improve, we can expect to see even more innovative applications for Titanium 6Al-4V Grade 5 sheet in the future. The ongoing development of additive manufacturing techniques, such as 3D printing with titanium alloys, may open up new possibilities for creating complex geometries and custom components that were previously impractical or impossible to manufacture.

However, it's important to note that while Titanium 6Al-4V Grade 5 sheet offers numerous advantages, its relatively high cost compared to more common materials like steel or aluminum can be a limiting factor in some applications. As such, its use is often reserved for situations where its unique properties provide significant benefits that justify the additional expense.

In conclusion, Titanium 6Al-4V Grade 5 sheet remains at the forefront of materials science, continually enabling advancements in various fields of engineering and technology. Its exceptional properties and wide range of applications ensure that it will continue to be a critical material in the development of next-generation products and solutions across multiple industries.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

1. The Analysis of the Physicochemical Properties of Benzocaine Polymorphs

2. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and titanium alloys: fundamentals and applications. John Wiley & Sons.

3. Donachie, M. J. (2000). Titanium: a technical guide. ASM international.

4. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials properties handbook: titanium alloys. ASM international.

5. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced engineering materials, 5(6), 419-427.

6. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

.webp)