- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why is Ti-6Al-7Nb Preferred for Medical Applications Over Other Alloys?

2024-09-14 15:35:35

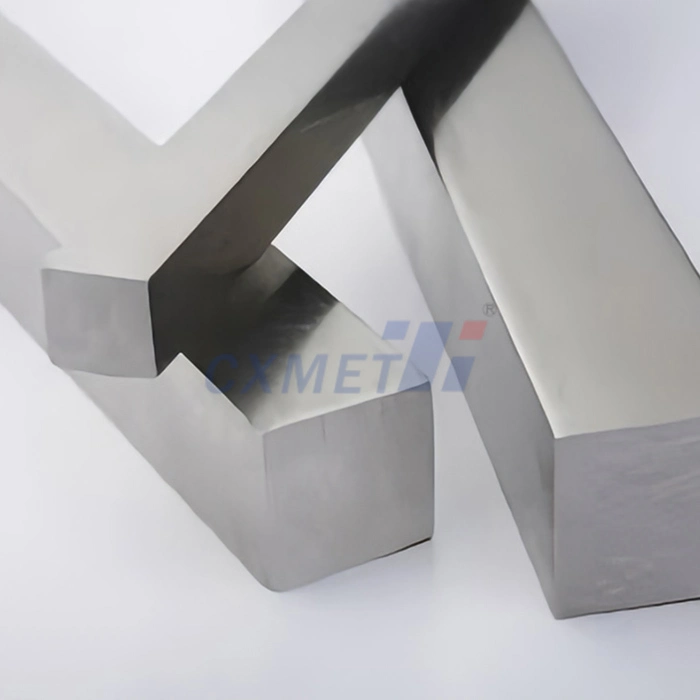

Titanium alloys have revolutionized the field of medical implants and devices due to their exceptional properties. Among these, Ti-6Al-7Nb has emerged as a preferred choice for many medical applications. This alloy, composed of titanium with 6% aluminum and 7% niobium, offers a unique combination of strength, biocompatibility, and corrosion resistance that makes it ideal for use in the human body. In this blog post, we'll explore why Ti-6Al-7Nb has become a go-to material in the medical industry and how it compares to other alloys.

What are the key properties of Ti-6Al-7Nb that make it suitable for medical implants?

Ti-6Al-7Nb possesses a remarkable set of properties that make it highly suitable for medical implants and devices. Firstly, its excellent biocompatibility is a crucial factor in its widespread adoption. The human body generally tolerates this alloy well, with minimal risk of adverse reactions or rejection. This biocompatibility stems from the formation of a stable oxide layer on the surface of the alloy, which acts as a barrier between the implant and surrounding tissues.

Another key property of Ti-6Al-7Nb is its impressive strength-to-weight ratio. This alloy offers high tensile strength and fatigue resistance while remaining relatively lightweight. For medical applications, this means that implants and devices made from Ti-6Al-7Nb can withstand the stresses of daily use without adding unnecessary weight to the patient's body. This is particularly important in orthopedic applications, where the implant must bear significant loads while maintaining long-term stability.

Corrosion resistance is another critical feature of Ti-6Al-7Nb. The human body presents a challenging environment for implants, with various bodily fluids and chemical processes that can potentially degrade materials over time. Ti-6Al-7Nb exhibits excellent resistance to corrosion, thanks in part to the protective oxide layer that forms on its surface. This resistance helps ensure the longevity of implants and reduces the risk of metal ions leaching into the surrounding tissues.

The alloy also demonstrates good osseointegration properties, which is the ability to form a strong bond with bone tissue. This characteristic is essential for orthopedic implants, as it promotes stable fixation and long-term success of the implant. The surface of Ti-6Al-7Nb can be modified through various treatments to enhance its osseointegration capabilities further, making it an versatile choice for a wide range of orthopedic applications.

Moreover, Ti-6Al-7Nb has a relatively low elastic modulus compared to other metallic implant materials. This property helps reduce the risk of stress shielding, a phenomenon where the implant bears too much of the load, leading to bone resorption around the implant. By more closely matching the elastic modulus of bone, Ti-6Al-7Nb implants can promote better load distribution and maintain bone health in the surrounding tissues.

The thermal expansion coefficient of Ti-6Al-7Nb is also compatible with that of human bone, which is advantageous for long-term implant stability. This similarity in thermal expansion helps minimize stresses at the bone-implant interface during temperature fluctuations, contributing to the overall success and durability of the implant.

How does Ti-6Al-7Nb compare to other titanium alloys in medical applications?

When comparing Ti-6Al-7Nb to other titanium alloys used in medical applications, several factors come into play. One of the most common comparisons is with Ti-6Al-4V, which has been a standard in the medical industry for many years. While both alloys offer excellent properties, Ti-6Al-7Nb has some distinct advantages that have led to its increasing popularity.

One significant difference lies in the composition of the alloys. Ti-6Al-7Nb replaces the vanadium found in Ti-6Al-4V with niobium. This substitution addresses concerns about the potential long-term effects of vanadium in the body. While the risks associated with vanadium are generally considered low, the use of niobium in Ti-6Al-7Nb eliminates this concern entirely, making it an attractive option for long-term implants.

In terms of mechanical properties, Ti-6Al-7Nb exhibits comparable strength to Ti-6Al-4V, with some studies suggesting slightly superior fatigue resistance. This makes Ti-6Al-7Nb equally suitable for load-bearing applications while potentially offering improved long-term performance. The similar strength profiles mean that existing designs for medical devices and implants can often be easily adapted from Ti-6Al-4V to Ti-6Al-7Nb without significant modifications.

Biocompatibility is another area where Ti-6Al-7Nb shines. While both alloys are considered highly biocompatible, some research indicates that Ti-6Al-7Nb may have a slight edge in terms of cellular response and tissue integration. This could translate to better overall performance in vivo, particularly for applications requiring close bone contact or soft tissue integration.

When compared to commercially pure titanium (CP-Ti), which is also used in some medical applications, Ti-6Al-7Nb offers significantly higher strength and better wear resistance. This makes Ti-6Al-7Nb more suitable for applications that require higher mechanical performance, such as joint replacements or dental implants. However, CP-Ti remains a good choice for applications where ultimate strength is less critical, and maximum biocompatibility is desired.

It's worth noting that while Ti-6Al-7Nb has many advantages, it may not be the best choice for every medical application. For instance, in cases where extreme corrosion resistance is required, such as in some cardiovascular applications, other alloys like Nitinol (a nickel-titanium alloy) might be preferred. Similarly, for some dental applications, zirconia-based ceramics might be chosen for their aesthetic properties.

The choice between Ti-6Al-7Nb and other alloys often comes down to the specific requirements of the application, including mechanical needs, biocompatibility considerations, and manufacturing processes. However, the overall balance of properties offered by Ti-6Al-7Nb makes it a versatile and increasingly popular choice across a wide range of medical applications.

What are the primary medical applications of Ti-6Al-7Nb, and why is it chosen for these uses?

Ti-6Al-7Nb finds applications across a wide spectrum of medical devices and implants, owing to its exceptional combination of properties. Understanding these applications and the reasons behind its selection can provide insight into the versatility and importance of this alloy in modern medicine.

One of the primary applications of Ti-6Al-7Nb is in orthopedic implants, particularly for joint replacements such as hip and knee prostheses. The alloy's high strength-to-weight ratio makes it ideal for these load-bearing applications, where the implant must withstand significant forces over many years. The low elastic modulus of Ti-6Al-7Nb, which is closer to that of bone compared to many other metallic implant materials, helps reduce stress shielding and promote better long-term bone health around the implant.

In the field of dental implants, Ti-6Al-7Nb has gained significant traction. Dental implants require a material that can integrate well with bone (osseointegration) while resisting the corrosive environment of the mouth and the mechanical stresses of chewing. Ti-6Al-7Nb meets these requirements admirably. Its excellent biocompatibility promotes the growth of bone cells on the implant surface, ensuring a strong and lasting connection between the implant and the jawbone. The corrosion resistance of the alloy is particularly important in the oral environment, where saliva and food particles can create challenging conditions for implant materials.

Spinal implants represent another area where Ti-6Al-7Nb excels. These implants, which include vertebral body replacements, interbody fusion cages, and pedicle screws, must maintain their structural integrity under complex loading conditions while promoting bone growth and integration. The high fatigue strength of Ti-6Al-7Nb makes it well-suited for these applications, where cyclic loading can lead to implant failure if not properly addressed. Additionally, the ability to create porous structures with Ti-6Al-7Nb through advanced manufacturing techniques like 3D printing allows for implants that better mimic the structure of natural bone, further enhancing osseointegration.

In the realm of trauma fixation devices, such as bone plates and screws, Ti-6Al-7Nb offers several advantages. Its strength allows for the creation of low-profile devices that provide robust fixation without excessive bulk. This is particularly beneficial in areas with limited soft tissue coverage, such as in craniomaxillofacial surgery. The biocompatibility of Ti-6Al-7Nb is also crucial in these applications, as these devices often remain in the body for extended periods and sometimes permanently.

Cardiovascular applications, while less common than orthopedic uses, also benefit from Ti-6Al-7Nb's properties. The alloy can be used in heart valve components and parts of artificial heart pumps. In these applications, the material's excellent fatigue resistance and biocompatibility are critical, as these devices must function flawlessly over millions of cycles in the demanding environment of the cardiovascular system.

The choice of Ti-6Al-7Nb for these various medical applications is driven by several factors. First and foremost is its biocompatibility, which minimizes the risk of adverse reactions and promotes better integration with the body's tissues. The mechanical properties of the alloy, including its high strength, low density, and fatigue resistance, make it suitable for a wide range of load-bearing applications. The corrosion resistance of Ti-6Al-7Nb is crucial in the physiological environment, where implants are exposed to bodily fluids and potential electrochemical reactions.

Another factor contributing to the selection of Ti-6Al-7Nb is its versatility in manufacturing processes. The alloy can be cast, forged, or machined using conventional techniques, allowing for the production of complex shapes and structures. More recently, the compatibility of Ti-6Al-7Nb with additive manufacturing techniques has opened up new possibilities for creating custom, patient-specific implants with optimized geometries and porous structures that promote tissue ingrowth.

The long-term performance of Ti-6Al-7Nb implants is another key consideration. The stability of the alloy in the body, combined with its resistance to wear and corrosion, contributes to the longevity of implants. This is particularly important in an aging population, where the durability of medical implants can significantly impact quality of life and reduce the need for revision surgeries.

In conclusion, Ti-6Al-7Nb has established itself as a preferred material for a wide range of medical applications due to its exceptional combination of biocompatibility, mechanical properties, and processability. From load-bearing orthopedic implants to dental prostheses and trauma fixation devices, this alloy continues to play a crucial role in advancing medical technology and improving patient outcomes. As research and development in biomaterials continue, Ti-6Al-7Nb is likely to remain at the forefront of medical implant materials, with ongoing refinements in composition, processing, and surface treatments further enhancing its performance and expanding its applications in the medical field.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.

2. Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 1(1), 30-42.

3. Sidambe, A. T. (2014). Biocompatibility of advanced manufactured titanium implants—A review. Materials, 7(12), 8168-8188.

4. Chen, Q., & Thouas, G. A. (2015). Metallic implant biomaterials. Materials Science and Engineering: R: Reports, 87, 1-57.

5. Cui, C., Liu, H., Li, Y., Sun, J., Wang, R., Liu, S., & Greer, A. L. (2005). Fabrication and biocompatibility of nano-TiO2/titanium alloys biomaterials. Materials Letters, 59(24-25), 3144-3148.

6. Okazaki, Y., & Gotoh, E. (2005). Comparison of metal release from various metallic biomaterials in vitro. Biomaterials, 26(1), 11-21.

7. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

8. Wang, K. (1996). The use of titanium for medical applications in the USA. Materials Science and Engineering: A, 213(1-2), 134-137.

9. Long, M., & Rack, H. J. (1998). Titanium alloys in total joint replacement—a materials science perspective. Biomaterials, 19(18), 1621-1639.

10. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.