- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

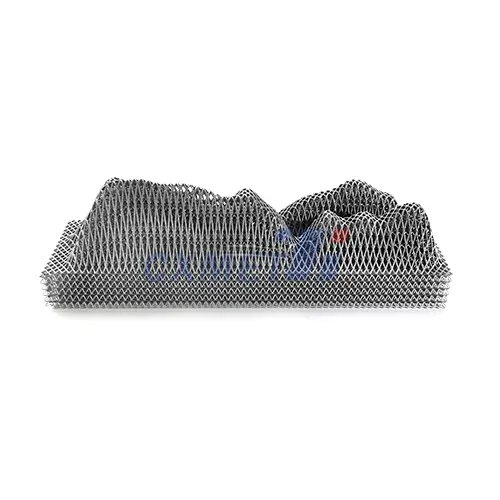

MMO Mesh Ribbon Anode

Place Of Origin: China

Application: Industry

Technique: Brush Coating

Grade: Gr1

Shape: Ribbon

Color: Black

Material: Gr1 titanium

Standard: ASTM Standard B265 Grade1

Coating: RuO2 / RuO2-IrO2

Certifacate: ISO 9001

Application: Reinforced Structures

Product Introduction

MMO Mesh Ribbon Anode, also known as Mixed Metal Oxide Ribbon Anode, is a high-performance, long-life anode designed primarily for cathodic protection of steel-reinforced concrete and buried metallic structures. It consists of a thin, flexible titanium substrate coated with a proprietary blend of noble metal oxides, such as iridium and ruthenium. These coatings offer exceptional electrochemical activity, enabling the anode to function effectively in harsh environments while delivering consistent current over an extended lifespan.

Shaanxi CXMET Technology Co., Ltd. specializes in the manufacturing of premium-quality MMO Mesh Ribbon Anodes tailored to meet a wide variety of project specifications and performance demands. With over two decades of technical experience in non-ferrous and refractory metals, we serve global industries with reliable, efficient, and customized cathodic protection solutions.

Our MMO Mesh Ribbon Anodes are lightweight, easy to install, cost-efficient, and corrosion-resistant, making them an ideal choice for complex infrastructure protection projects—especially in environments where oxygen or chloride is released, or in soil, brackish, and marine conditions.

Product Parameters

| Parameter | Specification |

|---|---|

| Base Material | Titanium (Grade 1 or Grade 2 ASTM B265) |

| Coating Material | Mixed Metal Oxide (IrO₂, Ta₂O₅, RuO₂, or customized) |

| Coating Thickness | 5–10 μm (customizable based on project requirements) |

| Standard Ribbon Width | 6.35 mm (0.25 inch) |

| Standard Ribbon Thickness | 0.635 mm (0.025 inch) |

| Weight | Approx. 1.1 lbs per 100 feet |

| Current Output Capacity | Up to 170 mA/m² (depending on electrolyte and coating) |

| Design Life | Up to 75 years (in concrete environments) |

| Operating Environment | Soil, Freshwater, Brackish Water, Seawater, Concrete |

| Operating Voltage Range | 6V–12V typical (varies with system design) |

| Application Temperature | Up to 80°C (176°F) |

| Current Distribution | Uniform across the ribbon surface |

| Installation | Surface-mounted or embedded |

| Customization Options | Width, Thickness, Coating Type, Current Output, Lifespan |

Key Features of MMO Mesh Ribbon Anode

Our MMO Mesh Ribbon Anodes are engineered for durability, efficiency, and ease of integration. Key features include:

-

Field-Friendly Flexibility: Can be easily cut and welded on-site to accommodate a wide range of structural geometries.

-

Simple Installation: Eliminates the need for expensive sawing and grouting processes, reducing labor time and cost.

-

Surface-Mount Design: Promotes uniform current distribution and minimizes the risk of short-circuiting steel reinforcement.

-

Low System Resistance: Ensures effective current flow with reduced energy consumption.

-

Ultra-Long Service Life: Designed to deliver consistent performance for over 75 years under proper operating conditions.

-

Lightweight Structure: A 100-foot roll (6.35 mm width) weighs slightly over 1 pound—ideal for easy handling and transportation.

-

Dimensionally Stable: Stable form factor prevents connection sealing issues and enhances mechanical reliability.

-

Cost-Efficient: High installation efficiency and low maintenance needs reduce the total life-cycle cost of your cathodic protection system.

Applications of MMO Mesh Ribbon Anode

Our MMO Mesh Ribbon Anode is highly adaptable and widely used across multiple infrastructure sectors. Key application areas include:

-

Bridge Substructures: Applied in concrete decks and piers to prevent corrosion of embedded steel reinforcement.

-

Underground Steel Installations: Used for buried pipelines, steel piles, and other below-grade metallic systems.

-

Reinforced Concrete Structures: Ideal for marine platforms, piers, parking garages, tunnels, and retaining walls.

-

Above-ground and Underground Storage Tanks: Prevents corrosion in tanks exposed to aggressive environments, such as wastewater or chemical storage.

|

|

|

|

|

|

Working Environments

Our MMO Mesh Ribbon Anodes perform reliably in a wide range of aggressive environments, including:

-

Oxygen- or Chloride-Releasing Environments: Designed for systems that release O₂, Cl₂, and other oxidizing species.

-

Soil: Excellent performance in both high-resistivity and low-resistivity soil types.

-

Freshwater and Brackish Water: Stable coating ensures corrosion resistance in neutral and slightly saline conditions.

-

Marine and Seawater Applications: Built to withstand the challenges of saline corrosion and tidal changes.

At Shaanxi CXMET, we understand that every project is unique. That’s why we offer fully customizable MMO Mesh Ribbon Anodes to match your specific technical requirements.

Customizable Options:

-

Dimensions: Width, thickness, and mesh size tailored to your structural needs.

-

Coating Thickness: Adjusted to meet performance longevity requirements.

-

Current Output: Tuned to suit your cathodic protection system's current density and voltage requirements.

-

Ribbon Flexibility: Available in standard or enhanced flexibility models for complex geometrical installations.

-

Expected Service Life: Coating life designed to exceed 75 years depending on usage conditions.

Functions of MMO Mesh Ribbon Anode

-

Delivers Controlled DC Current: Ensures uniform current distribution to suppress anodic corrosion in steel reinforcements.

-

Electrochemical Stability: Maintains performance without degradation under fluctuating environmental conditions.

-

Minimizes Maintenance Requirements: Once installed, the system requires minimal upkeep throughout its operational lifespan.

-

Optimizes System Efficiency: Reduces power consumption and enhances protection reliability over time.

Primary Advantages of MMO Mesh Ribbon Anode

-

Environmentally Friendly: Free from toxic by-products; supports sustainability in civil and industrial projects.

-

Energy-Saving Performance: Low voltage loss during electrochemical reaction processes.

-

High Adhesion to Structures: Can be directly bonded or mechanically affixed to concrete surfaces or rebar cages.

-

Compatibility: Works well with common power sources and monitoring systems used in cathodic protection.

Manufacturing Process & Production Workflow

Our MMO Mesh Ribbon Anode manufacturing process is precise, efficient, and quality-controlled at every step:

-

Titanium Substrate Preparation: Sourcing of Grade 1 or Grade 2 titanium mesh ribbons.

-

Surface Pretreatment: Cleaning, degreasing, and etching to promote adhesion.

-

Coating Application: Application of MMO coating using advanced thermal or electrochemical deposition methods.

-

Curing and Firing: High-temperature thermal processing to form a stable oxide layer.

-

Testing & Quality Control: Each batch undergoes conductivity, coating thickness, adhesion, and performance tests.

-

Packaging: Delivered in protective, easy-to-install rolls or pre-cut sections according to client specifications.

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us

High Quality: Only ASTM-certified raw materials

Advanced Equipment: Precision coating and welding machinery

Professional Team: 80+ skilled engineers and technicians

One-Stop Solution: From design to export logistics

Global Reach: Experience in 40+ export countries

Responsive Service: Fast quoting and technical support

OEM Services We provide full OEM/ODM support. Whether you require custom ribbon width, coating thickness, or special connectors, Shaanxi CXMET Technology Co., Ltd. can tailor the product to meet your exact application requirements.

FAQ

Q1: What is the standard service life of your MMO Mesh Ribbon Anode?

A1: Typically designed for a service life exceeding 75 years under normal conditions.

Q2: Can I get customized dimensions or coating types?

A2: Yes, we offer full customization including width, thickness, and coating formulation.

Q3: How is the anode installed in reinforced concrete?

A3: It can be surface-mounted using conductive adhesives or mechanically tied to the steel reinforcement grid.

Q4: Do you provide technical support for installation?

A4: Yes, our team provides installation guides and engineering assistance globally.

Q5: Are your products suitable for marine environments?

A5: Absolutely, our MMO coatings are highly resistant to chloride attack and saline corrosion.

Contact Us for Custom Quotes and Solutions

We welcome global buyers, contractors, and engineering consultants to partner with Shaanxi CXMET Technology Co., Ltd. for high-quality, customizable MMO Mesh Ribbon Anodes.

Email: sales@cxmet.com

Tel&WhatsApp: 8615891192169

Address: Shaanxi Titanium Valley, Baoji City, China

hotTags:MMO Mesh Ribbon Anode,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Nickel Round Bar

Product name: Nickel Bar

Brand: CXMET

Place Of Origin: China

Application: Industry, Used in chemical, oil,

Ni (Min) 99.9%

Package: Standard waterproof transport packaging

Surface: Polished

Certificate ISO9001:2015

Material: Nickel,Monel/Inconel/Hastelloy/Nickel Alloy

Gr9 Ti-3Al-2.5V titanium wire

Brand: CXMET

Place Of Origin: China

Shape: Coil Spool Straight

Available: Titanium Grade Gr9

Standard: ASTM F67 ASTM F136 ASTM B863

Condition: Cold rolled(Y)~Hot

rolled(R)~Annealed (M)~Solid Status

Color Metal color/Metallic

Application Industry,Medical,Aerospace etc

Surface Polished,Pickling etc

Titanium Material pure Titanium,alloy titanium

MMO Probe Anode

Brand: CXMET

Place Of Origin: China

Shape: Plate,Mesh,Tube and so on

Material: Titanium

Chemical Composition: 99.99% titanium

Color: Black

Usage: Cathodic Protection , Electrosynthesis ,Chlorate ,Perchlorate

Certificate: ISO9001

Standard :ASTM

Appearance: Smooth

Technology: Electroplate

Size: According to customer's requirement

Substrate Titanium,Niobium,Zirconium

MMO Wire Anode

Brand: CXMET

Place Of Origin:China

Application: Water heater

Technique: Push coating

Grade: Ti+MMO

Name: MMO wire anode for water heater

Shape: Wire

Material: GR1

Application: Chemical

Color: Black

Standard: ASTM B381

Technique: Brush Painting

MMO Powered Water Heater Anode Rod

Brand: CXMET

Place Of Origin: China

Shape: Rod

Material: MMO, Titanium

Chemical Composition: MMO, Titanium alloy

Other name: mmo titanium anode rod

Standard: ASTM B348

Life: 50years

Color: Black

Packing: Wooden Packing

Delivery Time: 30 Days

Copper Cored MMO Wire Anode

Brand: CXMET

Place Of Origin: China

Shape: Wire

Material: MMO

Chemical Composition: MMO

Structure: MMO titanium clad with copper

Material: Titanium and Copper

Standard: ASTM B348

Packing: Wooden Packing

Coating: Ir02, Ta2O5