- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

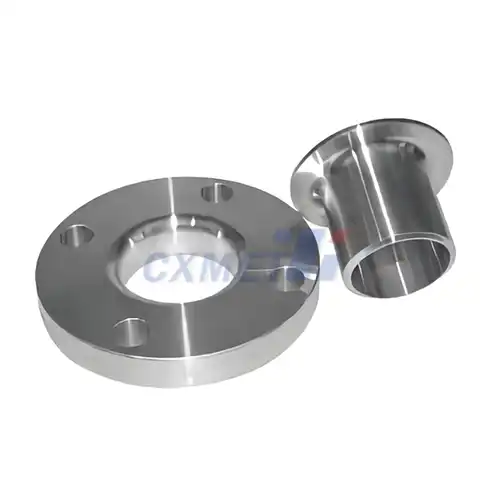

Titanium Slip-On Flange

Brand: CXMET

Place Of Origin: China

Titanium Reducing Flange

ASTM B381 Titanium Reducing Flanges

Basic Details:

The Titanium Slip-On Flange, crafted with precision and expertise by SHAANXI CXMET TECHNOLOGY CO., LTD., stands as a testament to innovation and quality in the realm of industrial fittings. Engineered from high-grade titanium, this flange epitomizes durability, reliability, and superior performance in diverse applications across industries.

Standards:

Our Titanium Slip-On Flange adheres to stringent international standards, including ASTM B381, ASME B16.5, ASME B16.47, and DIN 86029. These standards ensure consistency, quality, and compatibility, meeting the requirements of various industrial operations.

Basic Parameters:

| Parameter | Specification |

|---|---|

| Material | Titanium Grade 2 or Grade 5 |

| Size Range | 1/2" to 24" |

| Pressure Rating | Class 150 to Class 2500 |

| Temperature Range | -250°C to 800°C |

| Surface Finish | Smooth, Sandblasted, or Customized |

|

|

|

|

Attributes:

- Corrosion Resistance: Titanium's innate resistance to corrosion ensures longevity and reliability even in harsh environments.

- Lightweight: Despite its robustness, titanium's lightweight nature facilitates easy handling and installation.

- High Strength: Titanium's exceptional strength-to-weight ratio makes the flange capable of withstanding high-pressure applications.

- Biocompatibility: Suitable for use in medical and pharmaceutical industries due to its biocompatibility and inertness.

Functions:

The Titanium Slip-On Flange serves as a crucial component in piping systems, facilitating easy assembly and disassembly of pipelines while maintaining a tight seal under high pressure and temperature conditions. It acts as a connecting point between pipes, valves, and other equipment, ensuring seamless fluid flow in various industrial processes.

Features:

- Slip-On Design: Facilitates quick installation and removal, reducing downtime during maintenance.

- Precision Machining: Each flange undergoes meticulous machining processes to ensure dimensional accuracy and perfect fitment.

- Leak-proof Seal: The raised face design coupled with high-quality gaskets ensures a leak-proof connection, minimizing the risk of fluid or gas leakage.

- Versatility: Suitable for use in a wide range of industries including oil and gas, chemical processing, aerospace, and marine applications.

Advantages and Highlights:

- Exceptional Durability: Titanium's inherent strength and corrosion resistance make the flange durable and long-lasting, even in aggressive environments.

- Enhanced Performance: The precise engineering and quality craftsmanship result in superior performance, reducing maintenance costs and downtime.

- Environmental Compatibility: Titanium is recyclable and environmentally friendly, aligning with sustainable manufacturing practices.

Application Areas:

- Oil and Gas Industry: Offshore drilling rigs, refineries, and petrochemical plants.

- Chemical Processing: Chemical reactors, storage tanks, and pipelines.

- Aerospace: Aircraft components, fuel systems, and engine parts.

- Marine: Shipbuilding, desalination plants, and underwater pipelines.

OEM Services:

We offer comprehensive OEM services, allowing customization of the Titanium SO Flange to meet specific requirements, including size, pressure rating, and surface finish. Our experienced engineers and technicians work closely with clients to deliver tailored solutions that exceed expectations.

FAQs:

-

What is the difference between Grade 2 and Grade 5 titanium? Grade 2 titanium is commercially pure, while Grade 5 (Ti-6Al-4V) titanium alloy offers higher strength and heat resistance.

-

Can the flange be used in cryogenic applications? Yes, our Titanium Slip Flange is suitable for use in cryogenic environments, offering reliable performance at temperatures as low as -250°C.

-

Do you provide material test reports? Yes, we provide complete material test reports along with each batch of flanges, ensuring traceability and quality assurance.

About SHAANXI CXMET TECHNOLOGY CO., LTD.:

As a leading manufacturer and supplier of titanium products, SHAANXI CXMET TECHNOLOGY CO., LTD. specializes in producing high-quality Titanium Slip-On Flanges and other industrial fittings. With various standard certifications and complete test reports, we guarantee the reliability and performance of our products. Our OEM services, fast delivery, and meticulous packaging ensure customer satisfaction. For inquiries or custom orders, please contact us at sales@cxmet.com.

In conclusion, the Titanium Slip-On Flange from SHAANXI CXMET TECHNOLOGY CO., LTD. embodies excellence in design, engineering, and functionality, making it the preferred choice for discerning buyers and global dealers across industries.

hotTags:Titanium Slip-On Flange,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Titanium Lap Joint Flange

Brand: CXMET

Place Of Origin: China

Shape:Flange

Material:Titanium

Standards: ASME A182, ASME B16.5

Flange Thickness:11/16 in

Class/Pressure: Class 150

Titanium Weld Neck Flange

Brand: CXMET

Place Of Origin: China

Connection: Threaded

Material: Titanium

Application: General

Color: Silver

Size: 1/8"--4"

Certification: ISO 9001

Standard: ANSI

Body Material: titanium

Packaging Details: Wooden box

Titanium Socket Weld Flange

Brand: CXMET

Place Of Origin: China

Type: Titanium Tube Titanium Prices

Surface: Pickling

Shape: Round.Square.Rectangle

Processing: Processed

Test: Eddy Current Test

Advantage: High Performance

MOQ: 1pcs

Certificates: ISO9001:2008

Color: Sliver

Titanium Reducing Flange

Brand: CXMET

Place Of Origin: China

Material: Titanium Gr1, Gr2, Gr7, Gr12

Pressure: Class150/300/600/900//1500/2500

Size: All size

Color: Silver

MOQ: 1pcs

Application: Gas Oil Water System

Package: Plywooden Case

Titanium Flange Tube Sheet

Brand: CXMET

Place Of Origin:China

Material: Gr2

Size:Customized

Supply Condition: M (Anneal)

Standard: ASME B16.47 ANSI B16.5

Pressure Rating: 0.6~32Mpa

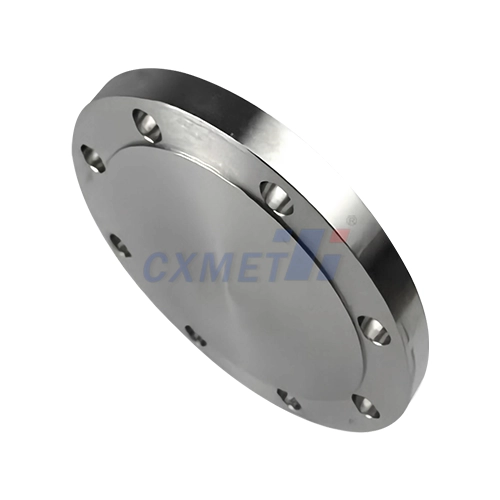

Titanium Blind Flange

Brand: CXMET

Place Of Origin: China

Material: Titanium

Size: Customized Size

MOQ: 50pcs

Package: Wooden Boxes Package

Stangard: ASTM B381

Rigid Magnesium Water Heater Anode Rod

Brand: CXMET

Place Of Origin: China

Material: Magnesium alloy

Chemical Composition: Magnesium

Purity: 99.95%

Standard: ASTM B843 M1C

Technology: Gravity Casting

Usage: Cathodic protection for buried pipeline

Capacity: >1100Amp.hr

Packing :Wooden Packing

Application: Environment >20 Ω/m