- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

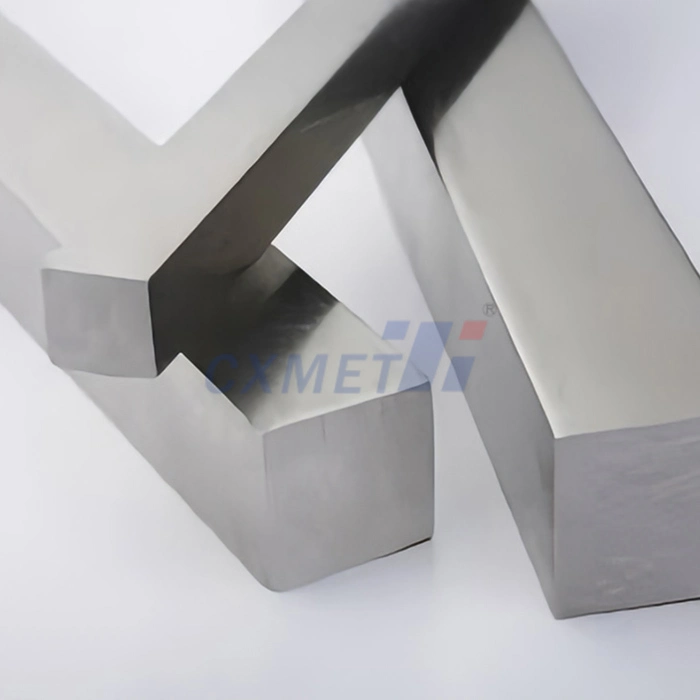

titanium 6Al-4V Grade 5 Round Bar

Place Of Origin: China

Type: Titanium Bars

Application: Medical

Technique: Hot Rolled

Grade: GR5

Shape: Round

Outer Diameter: 6-200mm

Titanium 6Al-4V Grade 5 Round Bar Product Introduction

Titanium 6Al-4V Grade 5 Round Bar is a high-performance titanium alloy known for its exceptional strength-to-weight ratio, excellent corrosion resistance, and outstanding heat resistance. As one of the most widely used titanium alloys across various industries, it contains approximately 6 percent aluminum and 4 percent vanadium. These alloying elements enhance its mechanical properties, making it ideal for demanding applications where strength, durability, and resistance to harsh environments are crucial.

Produced by Shaanxi CXMET Technology Co Ltd located in China Titanium Valley our Grade 5 round bars meet strict international standards for aerospace medical energy marine and industrial applications. The bars are available in a variety of diameters and lengths with tight tolerances and smooth surface finishes. We offer both standard and customized specifications to meet specific client needs. Our in-house quality control ensures every bar delivers consistent performance in structural load-bearing and corrosion-sensitive environments.

Key Features of Titanium 6Al-4V Grade 5 Round Bar

High Strength to Weight Ratio

Titanium Grade 5 provides a tensile strength of up to 895 MPa while remaining significantly lighter than steel

Excellent Corrosion Resistance

Resistant to seawater chlorides acids and a wide range of chemicals making it suitable for marine and chemical processing applications

Superior Heat Resistance

Maintains mechanical properties at elevated temperatures up to 400 degrees Celsius

Enhanced Fatigue and Creep Resistance

Ideal for components subjected to cyclic loading and long-term stress

Good Machinability

Although tougher to machine than some alloys with the right tools and techniques it can be precisely fabricated

Specifications of Titanium 6Al-4V Grade 5 Round Bar

| Parameter | Specification |

|---|---|

| Product Name | Titanium 6Al-4V Grade 5 Round Bar |

| Grade | Gr5 / Ti-6Al-4V (UNS R56400) |

| Standard | ASTM B348 / ASTM F136 / AMS 4928 |

| Diameter Range | Ø6 mm – Ø300 mm |

| Length | Up to 6000 mm (customized available) |

| Surface Finish | Polished, Pickled, Turned, Ground |

| Processing | Forged / Rolled / Machined |

| Tensile Strength | ≥895 MPa |

| Yield Strength | ≥828 MPa |

| Elongation | ≥10% |

| Density | 4.43 g/cm³ |

| Melting Point | ~1660°C |

| Certification | ISO 9001, EN 10204 3.1, SGS, TUV |

Applications of Titanium 6Al-4V Grade 5 Round Bar

Aerospace Components

Landing gear brackets fuselage frames engine parts

Automotive and Racing

Connecting rods valve retainers suspension components

Marine Equipment

Offshore platforms propeller shafts marine valves

Chemical Processing

Reactors heat exchangers piping systems

Energy Sector

Gas turbines nuclear plant components offshore oil equipment

Sports Equipment

High-performance bicycle frames golf club heads tennis rackets

|

|

|

|

|

|

Working Environment of Titanium 6Al-4V Grade 5 Round Bar

Titanium Grade 5 round bars are engineered for environments involving

High pressure and high temperature

Corrosive liquids and gases such as seawater and acidic chemicals

Biological contact including human body implants

Dynamic and vibration-loaded applications in aerospace and motorsports

Customization Options for Titanium 6Al-4V Grade 5 Round Bar

We understand the need for flexibility in modern engineering projects. At Shaanxi CXMET Technology Co Ltd we offer full customization for

Diameter and length

Mechanical property targets

Heat treatment conditions

Surface finish polish grind turn

Ultrasonic testing and third-party inspection

Packaging per client’s shipping conditions and labeling standards

Main Advantages of Titanium 6Al-4V Grade 5 Round Bar

Lightweight yet incredibly strong

Extended service life in aggressive environments

High-temperature strength retention

Low thermal expansion and excellent dimensional stability

Reduced maintenance and downtime

Environmentally safe and recyclable

Versatile use across industries and countries

Packaging and Logistics

We ensure safe and professional packaging to protect the titanium bars during transit. Our packaging includes

PE film protection and anti-rust paper

Strong wooden cases or steel frames

Custom labels including batch number specifications and compliance standards

All bars are securely packed to prevent deformation during shipping

Global delivery with flexible shipping options including sea air and land freight

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

FAQ

Q What is the lead time for titanium 6Al-4V bars

A Standard sizes are available from stock and can ship within 5 to 10 days Customized orders may take 15 to 30 days

Q Can I get a sample for testing

A Yes we provide small samples for material evaluation upon request

Q Do you provide mill test certificates

A Yes every batch comes with complete material test reports and certifications

Q Is the titanium bar suitable for welding

A Grade 5 titanium is weldable with proper shielding gas and welding techniques

Q Do you support OEM or private label

A Absolutely we provide OEM production and can print your logo or part number as required

Contact Us

We welcome global buyers to cooperate with Shaanxi CXMET Technology Co Ltd and benefit from our quality expertise and service

Email sales at sales@cxmet.com

Phone and WhatsApp 8615891192169

Let us help you find the right titanium solution for your project today

hotTags:titanium 6Al-4V Grade 5 Round Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Titanium 6Al7Nb Medical Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Rod

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Density: 4.5g/cm3

Gr12 Titanium Square Bar

Brand: CXMET

Place Of Origin: China Shape:Square

Grade: Gr12

Standard: ASTM B348

Technique: Rolling

Certificates: ISO 9001:2015

Gr5 Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Dia 10mm Titanium Rod In Medical

Brand: CXMET

Place Of Origin: China

Shape: Round

Grade: Gr5

Weight: According the dimension

Processing Service :Rolling, Ground

Material: titanium

Surface :Treatment Ground

MOQ: 10 KG

Standard :ASTM B348 ASTM F136

Package: Standard Wooden Case

Stock Size: Dia3-40mm Titanium Rod

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

.webp)

titanium Grade 2 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Grade: GR2

Shape: Round

Transport Package: As Your Requirements