- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

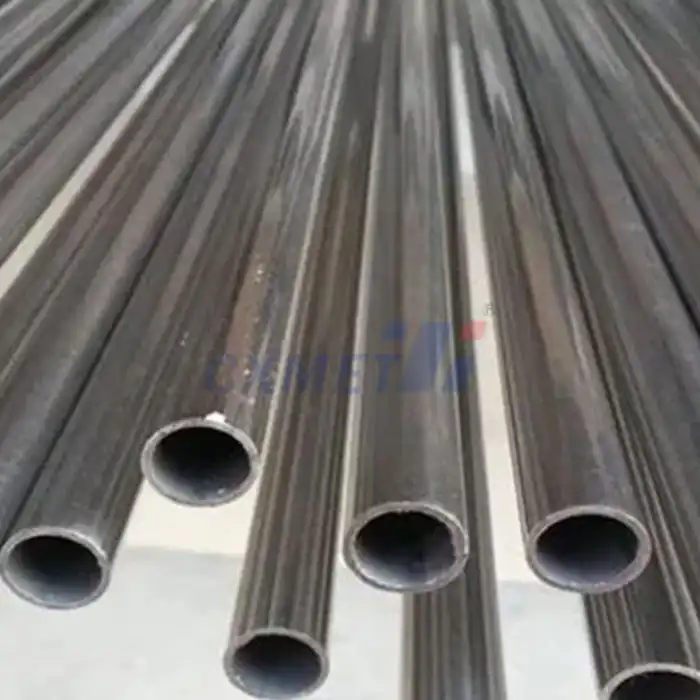

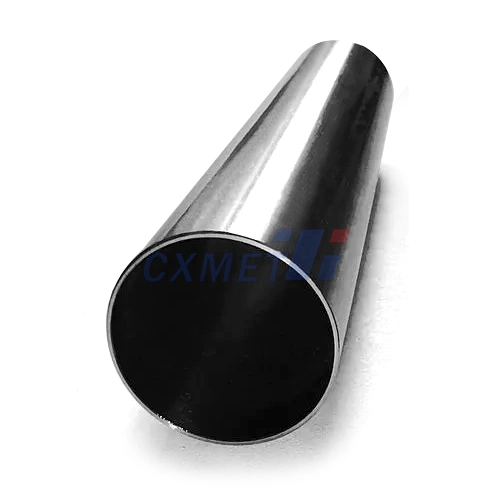

titanium alloy grade 9 pipe

Place Of Origin: China

Outer Diameter: 10mm - 500mm

Wall Thickness 1mm: - 20mm

Length: Customizable

Standard: ASTM B338,ASTM B86,1ASTM B862

Tensile Strength: 620 - 820 MPa

Yield Strength: 438 - 564 MPa

Elongation: 15 - 20%

Application: Aerospace,Chemical Processing,Medical

Product Introduction: titanium alloy grade 9 pipe

As a leading manufacturer and supplier of titanium alloy grade9 pipe, SHAANXI CXMET TECHNOLOGY CO., LTD. is proud to introduce our high-quality Titanium Alloy Grade 9 Pipe. Crafted with precision and designed for durability, our Grade 9 titanium pipes are engineered to meet the diverse needs of various industries. With a commitment to brilliance and advancement, we endeavor to convey items that surpass desires and set unused guidelines in the showcase.

Our titanium alloy grade 9 pipe is the epitome of precision engineering, leveraging advanced manufacturing techniques to ensure each pipe exhibits exceptional durability and strength. This alloy, renowned for its enhanced corrosion resistance compared to unalloyed titanium, withstands the onslaught of corrosive environments, including seawater, chloride-rich mediums, and acidic atmospheres. This resilience makes it an indispensable component in offshore oil rigs, chemical processing plants, and marine applications, where reliability and longevity are paramount.

Basic Product Details:

- Material: Titanium Alloy Grade 9 (Ti-3Al-2.5V)

- Product Type: Seamless Pipe

- Standard: ASTM B861/B861M, ASTM B338/B338M, ASTM B861/B861M, ASME SB861/SB861M

- Available Forms: Round, Square, Rectangular

- Sizes: Customizable as per client requirements

- Surface Finish: Polished, Pickled, Annealed

|

|

Product Attributes:

- Exceptional Corrosion Resistance

- High Strength-to-Weight Ratio

- Excellent Weldability and Formability

- Superior Biocompatibility

- Outstanding Performance at Elevated Temperatures

Product Functions:

- Transfer of fluids in corrosive environments

- Structural applications in aerospace, marine, and chemical industries

- Medical implants and surgical instruments

- Heat exchangers and condensers in power generation

Features:

- Seamless construction for enhanced strength and integrity

- Uniform wall thickness for consistent performance

- Precision engineering for tight tolerances

- Smooth surface finish for reduced friction and easy cleaning

Advantages and Highlights:

- Enhanced durability and longevity

- Reduced maintenance costs

- Lower life-cycle costs compared to traditional materials

- Eco-friendly and recyclable

- Wide range of applications across industries

Application Areas:

- Aerospace and Aviation

- Chemical Processing

- Oil and Gas

- Medical and Healthcare

- Marine and Shipbuilding

- Power Generation

OEM Services:

We provide OEM organizations to meet to the specific requisites of our clients. Our bunch of masters works closely with clients to make customized courses of action custom-made to their uncommon needs.

FAQs:

-

What is the maximum temperature tolerance of Grade 9 titanium pipes? Titanium alloy grade9 pipe can withstand temperatures up to 600°C (1112°F) without significant deformation or loss of mechanical properties.

-

Are Grade 9 titanium pipes suitable for welding? Yes, Grade 9 titanium pipes exhibit excellent weldability, making them suitable for various welding techniques including TIG, MIG, and laser welding.

-

Can Grade 9 titanium pipes be used in seawater applications? Yes, Grade 9 titanium pipes offer exceptional corrosion resistance and are well-suited for seawater applications in marine environments.

Material Properties and Details:

| Property | Value |

|---|---|

| Density | 4.48 g/cm³ |

| Tensile Strength | 483 MPa |

| Yield Strength | 380 MPa |

| Elongation | 15% |

| Modulus of Elasticity | 103 GPa |

| Thermal Conductivity | 7.2 W/m·K |

| Coefficient of Thermal Expansion | 8.4 x 10^-6/K |

| Melting Point | 1668°C (3034°F) |

| Electrical Conductivity | 3.1% IACS (International Annealed Copper Standard) |

About SHAANXI CXMET TECHNOLOGY CO., LTD.:

SHAANXI CXMET TECHNOLOGY CO., LTD. is a reputable manufacturer and supplier of thin wall titanium tubing, committed to delivering excellence in quality and service. With a focus on innovation and customer satisfaction, we offer various standard and customized solutions to meet the diverse needs of our clients. Our products are accompanied by comprehensive certifications and test reports, ensuring compliance with industry standards and regulations. We provide OEM services, fast delivery, and reliable packaging to ensure a seamless experience for our customers. For inquiries or orders, please contact us at sales@cxmet.com.

In conclusion, our Titanium Alloy Grade 9 Pipe stands as a testament to our dedication to quality and innovation. Engineered for superior performance and durability, 3 4 titanium tubing serves as a versatile solution for a wide range of applications across industries. With SHAANXI CXMET TECHNOLOGY CO., LTD., you can trust in our expertise and commitment to excellence.

hotTags:titanium alloy grade 9 pipe,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

gr2 titanium seamless tube

Brand: CXMET

Place Of Origin: China

Material: Ti alloy

Surface: Treatment Polishing

Usage: Car exhaust/heat exchanger/medical

Shape: Round tube

Thickness: 0.4-12.7mm

Certificate: ISO9001,testing report

Standard: ASTM B338/B861

ASTM B861 titanium tube

Brand: CXMET

Place Of Origin: China

Regular Grades: Gr.1, Gr.2, Gr.7, Gr.9, Gr.13

Seamless Pipe: OD 10-914.4mm WT: 1-32mm

Length: 3,000 – 12,000mm or other economical lengths

Finish: Mill finish, Polished, Annealed

Form: Straight

Type: Seamless

Grade5 titanium alloy tube

Brand: CXMET

Place Of Origin: China

Surface: Polished,bright finished,pickling, Sand-blast etc

Processing: Hot rolled,cold rolled,forge,cold drawn

Type: Tube,foil,roll,plate,rod etc

Test: Eddy Current test,Tensile Strength Test,Hydraulic Press test, etc

Certificates ISO9001:2008

Shape: Round Shape

Application: Industrial, Medical, Petrochemical Industry, etc

Ti3AL2.5VTitanium Alloy tube

Brand: CXMET

Place Of Origin: China

Mechanical Properties Metric

Hardness, Vickers 300

Tensile Strength, Ultimate 620 MPa

Tensile Strength, Yield 530 MPa

Elongation at Break 0.2

Charpy Impact 92.0 J

ASTM B862 titanium tube

Brand: CXMET

Place Of Origin: China

ASTM: B861/2 GR.7 physical

Properties:ASTM B861/2 GR7

Density: 4.51g/cm3

Grain size 3.0-7.0

Tensile strength: 270Mpa≥σb≤410Mpa

Yield strength :σb≥165Mpa

Elongation: δ≥27%

gr16 titanium tube

Brand: CXMET

Place Of Origin: China

Material: Titanium

Outer diameter: 60-210mm

Type: Gr16

Standard: AMS 4941,AMS 4942,AMS 4902,ASTM B337,ASTM B338,ASTM B861

Finish: Pickled,passivation,inside&outside, mechanical,polishing ,electro-polishing

Application:Industrial,medical,avation,salt-making ,petrochemical,metallurgy,electronics

gr12 titanium tube

Brand: CXMET

Place Of Origin: China

Specifications: ASTM B338 B337 B861 B862, ASME, DIN, DMS, JIS

Grade: Gr1, Gr2, Gr12, Gr12, Gr5, Gr7, Gr9, Gr11, Gr12 etc

O.D.: 5-600mm or as Customized

W.T.: 2-120mm or as customized

Length: 5-12m or as Customized

Surface Finish: Black, Bright, Polished, Rough Turned, NO.4 Finish, Matt Finish

Packaging Details: Waterproof bag + wooden case

End: Plain End, Bevelled End, Treaded

gr1 titanium seamless tube

Brand: CXMET

Place Of Origin: China

Material: Titanium

Length: 500~900mm

Application: Industrial

Technique: Seamless

Grade: Titanium Alloy

Processing Service: Bending, Welding, Decoiling, Cutting, Punching, welded

Material :Titanium tube pipes

Surface: Pickled,polished

Density: 4.51 G/cm3

Application: industry,medical

Type: Titanium alloy tube,welding tube pipes,seamless tube