- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Tantalum Tungsten Alloy sheet

Place Of Origin: China

Shape: sheet plate

Material: Tantalum Tungsten alloy

Size: Customzied

Usage: Electrical industry

MOQ: 1kg

Surface: Ground

Packing: Wooden Packing

Color: Grey

Density: 16.6g/cm3

Tantalum tungsten alloy sheet, a cutting-edge fabric built by SHAANXI CXMET TECHNOLOGY CO., LTD., speaks to a apex in advanced combination innovation. This item amalgamates the remarkable properties of tantalum and tungsten, advertising unparalleled execution over assorted applications. With fastidious consideration to detail and thorough quality control, we show a item that surpasses industry guidelines and reclassifies the boundaries of combination fabulousness.

Basic Product Details:

- Product Name: Tantalum Tungsten Alloy Sheet

- Material Composition: Tantalum (Ta) and Tungsten (W)

- Manufacturer: SHAANXI CXMET TECHNOLOGY CO., LTD.

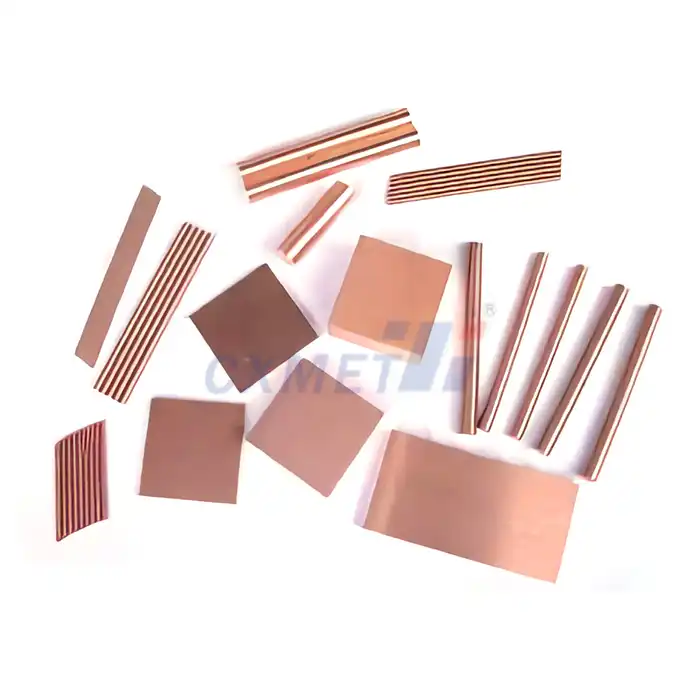

- Product Form: Sheets, rods, wires, foils, custom shapes

- Standard Grades: TaW10, TaW20, TaW30 (Custom grades available)

- Certifications: ISO 9001:2015, ASTM, AMS, ASME, DIN

Product Standards:

Our tantalum tungsten alloy conforms to rigorous international standards including ASTM, AMS, ASME, and DIN, ensuring reliability and consistency in performance across various applications. Each batch undergoes meticulous testing to guarantee compliance with these standards.

Basic Parameters:

| Property | TaW10 | TaW20 | TaW30 |

|---|---|---|---|

| Density (g/cm³) | 15.5 | 16.0 | 16.5 |

| Melting Point (°C) | 3010 | 2980 | 2950 |

| Tensile Strength (MPa) | 500 | 600 | 700 |

| Hardness (HV) | 250 | 300 | 350 |

|

|

|

|

Product Attributes:

- High Density: Tantalum-tungsten alloy boasts exceptional density, making it ideal for applications requiring weight and space efficiency.

- High Melting Point: With a melting point surpassing 2900°C, this alloy maintains structural integrity in extreme temperature environments.

- Superior Mechanical Properties: Tantalum tungsten alloy exhibits excellent tensile strength and hardness, ensuring durability and longevity in demanding conditions.

- Corrosion Resistance: Resistant to corrosion and oxidation, this alloy is suitable for use in harsh chemical and corrosive environments.

- Good Machinability: Despite its high density and hardness, tantalum tungsten alloy can be machined and formed with relative ease, offering versatility in manufacturing processes.

Product Functions:

Tantalum tungsten alloy serves as a key component in a myriad of applications across industries such as aerospace, defense, electronics, and medical technology. Its unique combination of properties makes it indispensable in critical applications where performance and reliability are paramount.

Features:

- Precision Engineering: Our TaW alloy is engineered with precision to meet the exacting demands of modern technology.

- Customizable: Available in various grades and forms, including sheets, rods, wires, and foils, with custom shapes and sizes upon request.

- Wide Temperature Range: With a high melting point and exceptional thermal stability, this alloy performs reliably across a broad temperature spectrum.

- Longevity: Exceptional durability ensures extended service life, reducing maintenance costs and downtime.

Advantages and Highlights:

- Exceptional Performance: Tantalum tungsten alloy offers unmatched performance in terms of strength, durability, and corrosion resistance.

- Versatility: Suitable for a wide range of applications, from high-temperature components to corrosive environments.

- Reliability: Manufactured to the highest standards, our TaW alloy delivers consistent performance in even the most demanding conditions.

- Customization: Tailored solutions are available to meet specific requirements, ensuring optimal performance in every application.

Application Areas:

- Aerospace and Defense: Engine components, missile guidance systems, armor-piercing projectiles.

- Electronics: High-power resistors, semiconductor components, electrical contacts.

- Medical Technology: Surgical instruments, radiation shielding, implantable devices.

- Chemical Processing: Reaction vessels, heat exchangers, valve components.

Material Highlight:

Tantalum Tungsten Alloy the special properties of tantalum and tungsten to make a fabric with extraordinary execution characteristics. Tantalum contributes erosion resistance, ductility, and biocompatibility, whereas tungsten improves hardness, quality, and high-temperature steadiness. This synergistic combination makes tantalum tungsten combination an perfect choice for applications where unwavering quality, toughness, and execution are fundamental.

OEM Services:

SHAANXI CXMET TECHNOLOGY CO., LTD. offers comprehensive OEM services, providing customized solutions to meet the unique requirements of our clients. From material selection to final product design, our team works closely with customers to deliver tailored solutions that exceed expectations.

FAQs:

-

What are the key properties of tantalum tungsten alloy?

- High density, high melting point, exceptional mechanical properties, and corrosion resistance.

-

What forms are available for tantalum tungsten alloy?

- Sheets, rods, wires, foils, and custom shapes according to customer specifications.

-

Is tantalum tungsten alloy suitable for high-temperature applications?

- Yes, it exhibits excellent thermal stability and can withstand extreme temperatures.

-

Can tantalum tungsten alloy be machined easily?

- Despite its high hardness, it can be machined and formed using standard techniques.

In conclusion, SHAANXI CXMET TECHNOLOGY CO., LTD. stands as a premier manufacturer and supplier of tantalum tungsten alloy, offering unparalleled quality, customization options, and customer service. With a commitment to excellence and innovation, we provide solutions that drive success across industries worldwide. For inquiries or to explore our OEM services, please contact us at sales@cxmet.com.

hotTags:Tantalum Tungsten Alloy sheet,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Tungsten Copper alloy rod bar

Brand: CXMET

Place Of Origin: China

Shape: Rod ,Plate ,Block

Material: Tungsten Copper Alloy

Name: Tungsten Copper Alloy bar rod

Standard: GB/T 8320-2003

Certificate: ISO9001:2015

Tungsten Heavy Alloy rod

Brand: CXMET

Place Of Origin: China

Shape: Plate,Rod

Material: Tungsten alloy

Purity: 90%-99.95%

Application: Industry

Color: Bright

Size: Customized

Usage :Electronics Industry

Packing :Wooden Packing

Niobium Hafnium Alloy bar

Brand: CXMET

Place Of Origin: China

Material: R04295 (Nb-10Hf), Nb-10W-10Hf,

(Niobium-10%Tungsten-10%Hafnium),C103

Specification:ASTM B652,ASTM B394,ASTM B655,ASTM B652

Niobium Nickel Alloy sheet

Brand: CXMET

Place Of Origin: China

Shaped: Plate ,Rod ,Block

Compound Formula NiNb

Molecular Weight 151.6

Appearance Solid

Exact Mass 150.841721

Monoisotopic Mass 150.841721

Niobium Zirconium Alloy Bar

Brand: CXMET

Place Of Origin: China

Shape: round

Material: zirconium ,zirconium alloy

Size: Customers' Requirements

MOQ: 1kg

Density: 6.51g/cm3

Package: Wooden Case

Grade: R60702,R60702, R60704, R60705

tantalum niobium alloy bar

Brand: CXMET

Place Of Origin: China

Shape: Sheet/Block/Bar

Material: Niobium Tantalum Alloy

Color: Natura

Process: Forging + Rolling + Grinding + Polishing

Surface: Treatment grinding and polishing

Certificate ISO 9001:2008

Molybdenum Niobium Alloy Sputtering Targets

Brand: CXMET

Place Of Origin: China

Shape: Customized

Material: Molybdenum Niobium Alloy

Color: Silver

Size: Customize

Packing: Customize

Certificate: ISO9001:2015

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial