- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Aadvantages of Using MMO Probe Anodes?

Mixed Metal Oxide (MMO) Probe Anodes have become increasingly popular in cathodic protection systems due to their numerous advantages over traditional anode materials. These advanced anodes offer superior performance, longevity, and efficiency in various applications, making them a preferred choice for corrosion protection in industries such as oil and gas, water treatment, and infrastructure. In this blog post, we'll explore the key benefits of using MMO Probe Anodes and address some common questions about their implementation and effectiveness.

How do MMO Probe Anodes compare to traditional anode materials?

MMO Probe Anodes offer several significant advantages over traditional anode materials such as graphite, high-silicon cast iron, or platinum-coated anodes. To fully understand these benefits, it's essential to examine the key differences in their composition, performance, and longevity.

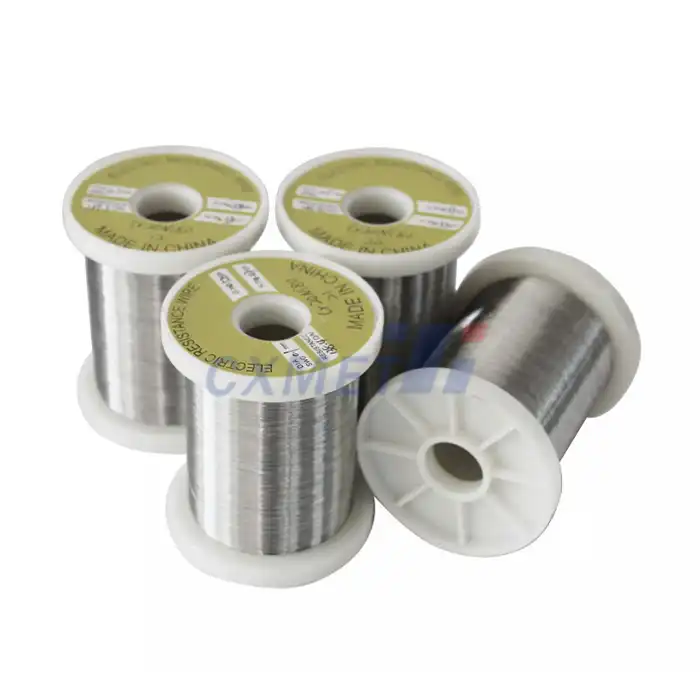

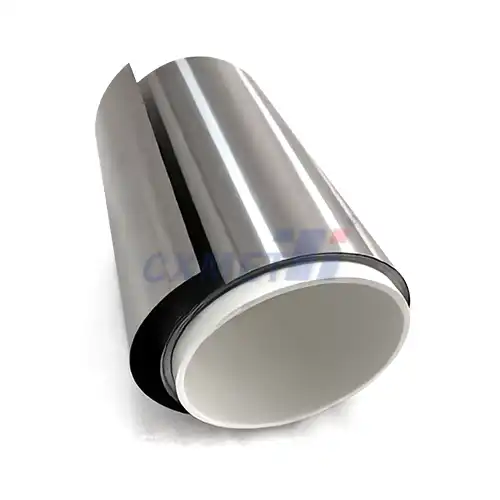

Composition: MMO Probe Anodes are typically made of a titanium substrate coated with a mixture of precious metal oxides, such as iridium, ruthenium, and tantalum. This unique composition gives them superior electrochemical properties compared to traditional materials. The titanium substrate provides excellent mechanical strength and corrosion resistance, while the mixed metal oxide coating ensures optimal current distribution and low consumption rates.

Performance: One of the most significant advantages of MMO Probe Anodes is their exceptional performance in various environments. They exhibit a much lower anode consumption rate compared to traditional materials, which means they can maintain a stable output over extended periods. This stability translates to more consistent and reliable cathodic protection, reducing the risk of localized corrosion and extending the life of protected structures.

MMO Probe Anodes also have a lower operating voltage requirement, which results in reduced power consumption and improved energy efficiency. This characteristic is particularly beneficial in remote locations or offshore applications where power sources may be limited or costly.

Longevity: The durability of MMO Probe Anodes is one of their most compelling advantages. Traditional anode materials often suffer from rapid deterioration, especially in harsh environments or when subjected to high current densities. In contrast, MMO Probe Anodes can last significantly longer, with some installations lasting up to 20 years or more under proper operating conditions.

This extended lifespan not only reduces the frequency of anode replacements but also minimizes system downtime and maintenance costs. For large-scale infrastructure projects or offshore installations, where access for maintenance can be challenging and expensive, the longevity of MMO Probe Anodes provides a substantial economic benefit.

Versatility: MMO Probe Anodes demonstrate excellent versatility across various applications and environments. They perform well in both freshwater and seawater, making them suitable for a wide range of industries, including marine structures, pipelines, and water treatment facilities. Their ability to maintain effectiveness in different soil resisti

What factors should be considered when designing a cathodic protection system with MMO Probe Anodes?

Designing an effective cathodic protection system using MMO Probe Anodes requires careful consideration of several key factors to ensure optimal performance and longevity. By addressing these elements during the design phase, engineers can maximize the benefits of MMO Probe Anodes and create a robust corrosion protection system.

Environment Assessment: The first step in designing a cathodic protection system is to thoroughly assess the environment in which the anodes will be installed. This includes analyzing soil resistivity, water chemistry, temperature variations, and potential mechanical stresses. MMO Probe Anodes perform well in a wide range of conditions, but understanding the specific environmental challenges helps in optimizing their placement and configuration.

For instance, in high-resistivity soils, it may be necessary to use a greater number of anodes or implement a deep anode bed system to ensure adequate current distribution. In marine environments, considerations such as tidal variations and seawater conductivity play crucial roles in anode placement and sizing.

Current Density Requirements: Determining the appropriate current density is critical for effective cathodic protection. This involves calculating the total surface area of the structure to be protected and estimating the required current output to achieve adequate polarization. MMO Probe Anodes can handle higher current densities compared to traditional anodes, which allows for more flexibility in system design.

However, it's essential to balance the current output with the anode's consumption rate to ensure long-term effectiveness. Over-designing the system with excessive current can lead to unnecessary power consumption and potential damage to the protected structure, while under-designing may result in inadequate protection.

Anode Spacing and Configuration: The spacing and configuration of MMO Probe Anodes within the cathodic protection system significantly impact its effectiveness. Proper spacing ensures uniform current distribution across the protected structure, preventing areas of under-protection or over-protection. Factors such as soil resistivity, structure geometry, and interference from nearby metallic objects influence the optimal anode configuration.

In some cases, a distributed anode system might be preferable, where multiple smaller anodes are placed at regular intervals. In other situations, a centralized deep anode bed might be more suitable, especially for protecting large underground structures or in areas with limited surface access.

System Monitoring and Control: Incorporating robust monitoring and control mechanisms is crucial for maintaining the long-term effectiveness of a cathodic protection system using MMO Probe Anodes. This includes installing reference electrodes to measure structure-to-electrolyte potentials and implementing remote monitoring systems for real-time data collection and analysis.

Advanced control systems can adjust the current output based on environmental changes or variations in protection requirements, ensuring optimal performance while minimizing energy consumption. Regular monitoring also helps in identifying any issues early, allowing for timely maintenance and preventing potential system failures.

How does the cost-effectiveness of MMO Probe Anodes compare to other cathodic protection methods?

When evaluating the cost-effectiveness of MMO Probe Anodes compared to other cathodic protection methods, it's essential to consider both the initial investment and the long-term operational costs. While MMO Probe Anodes may have a higher upfront cost compared to some traditional anode materials, their superior performance and longevity often result in significant cost savings over the life of the cathodic protection system.

Initial Investment: The initial cost of implementing a cathodic protection system with MMO Probe Anodes is typically higher than systems using traditional materials like graphite or high-silicon cast iron anodes. This higher cost is primarily due to the advanced materials and manufacturing processes involved in producing MMO anodes. However, it's crucial to view this initial investment in the context of the system's entire lifecycle.

When considering the initial costs, factors such as anode quantity, installation complexity, and supporting infrastructure (e.g., power supplies, monitoring equipment) should be taken into account. In some cases, the higher efficiency of MMO Probe Anodes may allow for a reduction in the total number of anodes required, partially offsetting the higher per-unit cost.

Operational Efficiency: One of the key advantages of MMO Probe Anodes is their superior operational efficiency. These anodes require lower operating voltages compared to traditional materials, resulting in reduced power consumption. In applications where energy costs are significant, such as offshore platforms or remote pipeline systems, the energy savings over time can be substantial.

The lower power requirements of MMO Probe Anodes also translate to reduced strain on power supply systems, potentially allowing for smaller, more cost-effective power units or extended battery life in remote installations. This efficiency not only contributes to cost savings but also aligns with increasingly important sustainability goals in many industries.

Maintenance and Replacement Costs: Perhaps the most significant factor in the cost-effectiveness of MMO Probe Anodes is their extended lifespan and reduced maintenance requirements. Traditional anodes often require frequent replacement, sometimes as often as every 2-5 years, depending on the application and environmental conditions. In contrast, MMO Probe Anodes can last 15-20 years or more under proper operating conditions.

This extended lifespan dramatically reduces the frequency of anode replacements, which can be a costly and time-consuming process, especially in underwater or underground installations. The reduction in maintenance operations not only saves on material costs but also minimizes system downtime and labor expenses associated with replacement activities.

System Reliability and Performance: The superior performance and reliability of MMO Probe Anodes contribute significantly to their cost-effectiveness. These anodes provide more consistent and stable current output over their lifetime, ensuring more reliable corrosion protection. This reliability reduces the risk of localized corrosion failures, which can lead to costly repairs or even catastrophic failures in critical infrastructure.

The improved performance of MMO Probe Anodes can also extend the life of the protected structures, potentially delaying major capital expenditures on infrastructure replacement or rehabilitation. This long-term benefit, while sometimes challenging to quantify precisely, can represent substantial cost savings for asset owners.

Scalability and Flexibility: MMO Probe Anodes offer greater scalability and flexibility compared to some traditional cathodic protection methods. Their ability to handle higher current densities allows for easier system expansions or modifications as protection requirements change over time. This adaptability can result in cost savings by reducing the need for complete system overhauls when expanding or modifying protected structures.

In conclusion, while the initial investment in MMO Probe Anodes may be higher, their superior performance, longevity, and efficiency often result in significant cost savings over the life of the cathodic protection system. When evaluating the cost-effectiveness of different cathodic protection methods, it's crucial to consider the total lifecycle costs, including installation, operation, maintenance, and replacement expenses. For many applications, especially those involving critical infrastructure or challenging environments, the long-term benefits of MMO Probe Anodes can provide a compelling economic advantage over traditional cathodic protection methods.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Baeckmann, W. V., Schwenk, W., & Prinz, W. (1997). Handbook of cathodic corrosion protection. Gulf Professional Publishing.

2. Bushman, J. B. (2001). Galvanic anode cathodic protection system design. NACE International.

3. Cramer, S. D., & Covino, B. S. (2003). ASM handbook, volume 13A: corrosion: fundamentals, testing, and protection. ASM international.

4. DNV-RP-B401. (2017). Cathodic protection design. Det Norske Veritas.

5. Gurrappa, I. (2005). Cathodic protection of cooling water systems and selection of appropriate materials. Journal of materials processing technology, 166(2), 256-267.

6. NACE SP0169. (2013). Control of external corrosion on underground or submerged metallic piping systems. NACE International.

7. Peabody, A. W. (2001). Peabody's control of pipeline corrosion. NACE international.

8. Roberge, P. R. (2008). Corrosion engineering: principles and practice. McGraw-Hill Education.

9. Shreir, L. L., Jarman, R. A., & Burstein, G. T. (1994). Corrosion: metal/environment reactions. Butterworth-Heinemann.

10. Tezdogan, T., & Demirel, Y. K. (2014). An overview of marine corrosion protection with a focus on cathodic protection and coatings. Brodogradnja: Teorija i praksa brodogradnje i pomorske tehnike, 65(2), 49-59.