- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

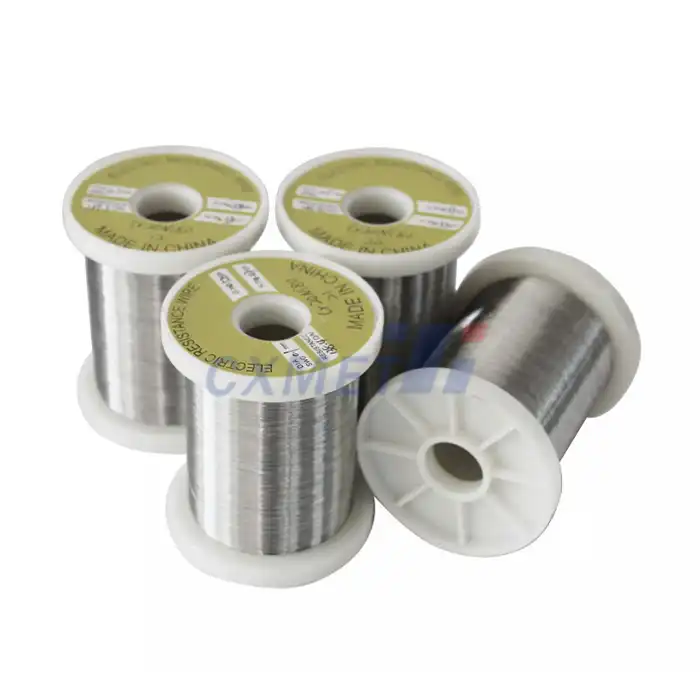

Nickel-Chromium Alloy Welding Wire

Place Of Origin: China

Application: Electronics,Welding , Repair

Type Rich

Condition soft wire, semi-soft wire, hard wire

Wire Gauge: 0.05-20mm

Package: 5/15/20kg/spool

Nickel-Chromium Alloy Welding Wire is a specialized welding fabric outlined for high-temperature applications, erosion resistance, and toughness. Fabricated utilizing progressed methods, this Inconel 600 Welding Wire offers uncommon execution and unwavering quality in different mechanical settings. At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in being a driving producer and provider of Nickel-Chromium Amalgam Welding Wire, catering to the assorted needs of proficient buyers and worldwide merchants.

Product Standards:

Our Inconel 600 Welding Wire conforms to international standards such as ASTM B164 and AWS A5.14, ensuring consistent quality and compliance with industry regulations.

Basic Parameters:

| Parameter | Value |

|---|---|

| Composition | Nickel-Chromium Alloy |

| Diameter | 0.8mm - 4.0mm |

| Tensile Strength | ≥600 MPa |

| Elongation | ≥30% |

| Melting Range | 1300°C - 1400°C |

| Density | 8.4 g/cm³ |

|

|

|

Product Attributes:

- High temperature resistance

- Excellent corrosion resistance

- Superior mechanical properties

- Consistent and stable welding performance

Product Functions:

Nickel-Chromium Alloy Welding Wire is primarily used for joining materials in high-temperature environments, such as in the aerospace, automotive, and chemical processing industries. It ensures strong and reliable bonds, even in challenging conditions.

Features:

- Low coefficient of thermal expansion

- Resistance to oxidation and scaling

- Good weldability and flow characteristics

- Minimal distortion during welding

Advantages and Highlights:

- Enhanced durability for prolonged service life

- Versatile application across various industries

- High-quality material for critical welding operations

- Precision manufacturing for uniformity and reliability

Application Areas:

- Aerospace components

- Chemical processing equipment

- High-temperature furnaces

- Power generation facilities

- Automotive exhaust systems

OEM Services:

At SHAANXI CXMET TECHNOLOGY CO., LTD, we offer OEM services to meet the specific requirements of our clients. Our experienced team can customize Nickel-Chromium Alloy Welding Wire according to your specifications, ensuring optimal performance and compatibility with your applications.

FAQs:

-

What is the melting point of Nickel-Chromium Alloy Welding Wire?

- The softening run is between 1300°C and 1400°C, giving fabulous solidness at tall temperatures.The softening point of Nickel-Chromium Combination Inconel 600 Welding Wire changes depending on the particular composition of the combination. Generally, Nickel-Chromium alloys are known for their high melting points, making them suitable for applications in high-temperature environments such as welding.Nickel-Chromium alloys typically contain a combination of nickel and chromium, with additional elements such as iron, molybdenum, and sometimes other metals like copper or cobalt. These alloys are valued for their excellent resistance to corrosion, oxidation, and high-temperature strength.

-

Can this welding wire be used for stainless steel applications?

- Yes, Nickel-Chromium Alloy Welding Wire is suitable for joining stainless steel components, offering superior corrosion resistance and mechanical strength.Stainless steel welding typically requires specialized welding consumables that match the composition of the base metal and provide the desired mechanical properties, corrosion resistance, and aesthetic appearance of the final weld. While some Inconel 601 Welding Wires are specifically designed for stainless steel welding, others may not be suitable due to differences in composition and performance characteristics.If the Inconel 601 Welding Wire in question is designed for Nickel-Chromium alloys or other materials, it may not be the best choice for welding stainless steel. Stainless steel welding wires are typically made from austenitic, ferritic, or duplex stainless steel alloys, which offer excellent corrosion resistance, strength, and weldability.

-

Is certification available for this product?

- Yes, we provide various standard and customized certifications, along with complete test reports, ensuring compliance with industry standards and regulations.When evaluating the certification status of a welding wire product, it's essential to consider the specific requirements of the welding application, the applicable industry standards, and any regulatory requirements that may apply. Certification can provide confidence in the product's quality and suitability for its intended use, helping ensure the integrity of weld joints and the safety of welding operations.

About SHAANXI CXMET TECHNOLOGY CO., LTD:

As a professional Nickel-Chromium Alloy Welding Wire manufacturer and supplier, SHAANXI CXMET TECHNOLOGY CO., LTD is committed to delivering top-quality products and exceptional customer service. We offer fast delivery, secure packaging, and comprehensive support for testing and customization. For inquiries or orders, please contact us at sales@cxmet.com

Conclusion:

Nickel-Chromium Alloy Welding Wire from SHAANXI CXMET TECHNOLOGY CO., LTD is the ideal choice for demanding welding applications requiring high temperature resistance and corrosion protection. With our commitment to quality and customer satisfaction, we strive to be your preferred partner for all your welding material needs.

hotTags:Nickel-Chromium Alloy Welding Wire,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

MMO Mesh Ribbon Anode

Brand: CXMET

Place Of Origin: China

Application: Industry

Technique: Brush Coating

Grade: Gr1

Shape: Ribbon

Color: Black

Material: Gr1 titanium

Standard: ASTM Standard B265 Grade1

Coating: RuO2 / RuO2-IrO2

Certifacate: ISO 9001

Application: Reinforced Structures

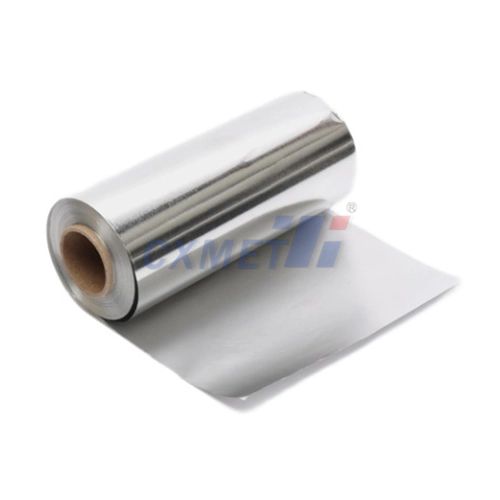

Nickel Foil

Brand: CXMET

Place Of Origin: China

Grade: Nickle Material

Ni (Min): 99.5%min.

Density: 8.9 G/cm3

Surface: Bright

Technique: Cold Rolled ,Hot Rolled

Size: 0.1mm

Certificate: ISO 9001:2008

Nickel Round Bar

Product name: Nickel Bar

Brand: CXMET

Place Of Origin: China

Application: Industry, Used in chemical, oil,

Ni (Min) 99.9%

Package: Standard waterproof transport packaging

Surface: Polished

Certificate ISO9001:2015

Material: Nickel,Monel/Inconel/Hastelloy/Nickel Alloy

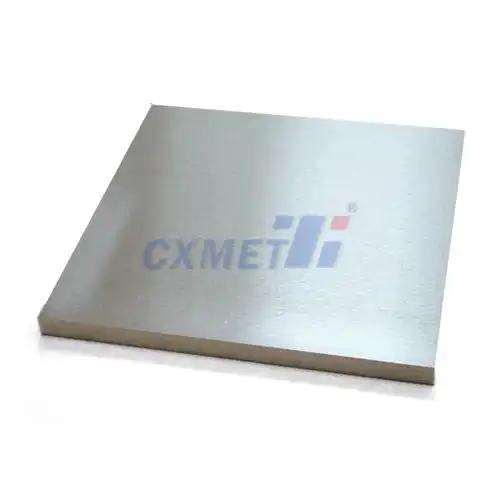

Pure Nickel Sheet

Brand: CXMET

Place Of Origin: China

Application: Building , Machine

Grade inconel 600 625 incoloy800 N04400 N08020 N08367

Ni (Min): 58%

Shape: Flat Sheet

Material: pure niobium

Technique: Cold Rolled Hot Rolled

Size: Customized Size

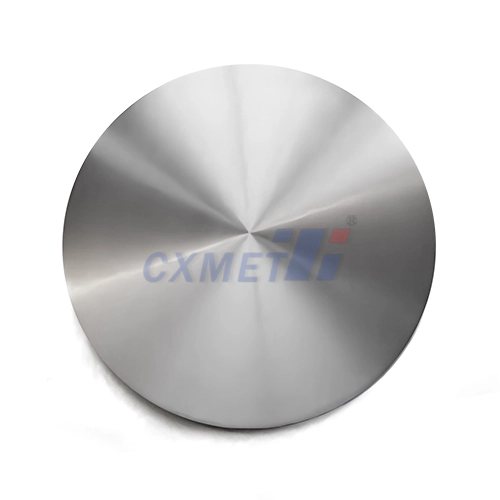

Tantalum Disc

Brand: CXMET

Place Of Origin: China

Shape: Round disc

Material: Pure tantalum

Color: Metal Color

Purity: >99.93%

Standard: ASTM B708

Surface: Cold rolled or Machined

MOQ: 1KG

Gr5 Ti6Al4V titanium wire

Brand: CXMET

Place Of Origin: China

Diameter: 0.1-2mm

Grade: Gr5, ti 6al-4v, ti 6 4 titanium alloy

Ti (Min): 99.5%

.webp)

titanium Grade 2 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Grade: GR2

Shape: Round

Transport Package: As Your Requirements

1.webp)

Half Shell Aluminum Bracelet Anode

Brand: CXMET

Place Of Origin: China

Shape: Arc shaped

Material: Aluminium

Chemical Composition: Aluminium alloy

Purity: 93.5%

Color: Silver Gray

Usage: Condenser, heat treatercore c/w bolt core for easy installation

Packing: Wooden Packing

Process: Casting