- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Benefits of Using Gr7 Titanium Wire in Medical Applications?

2025-01-02 15:05:16

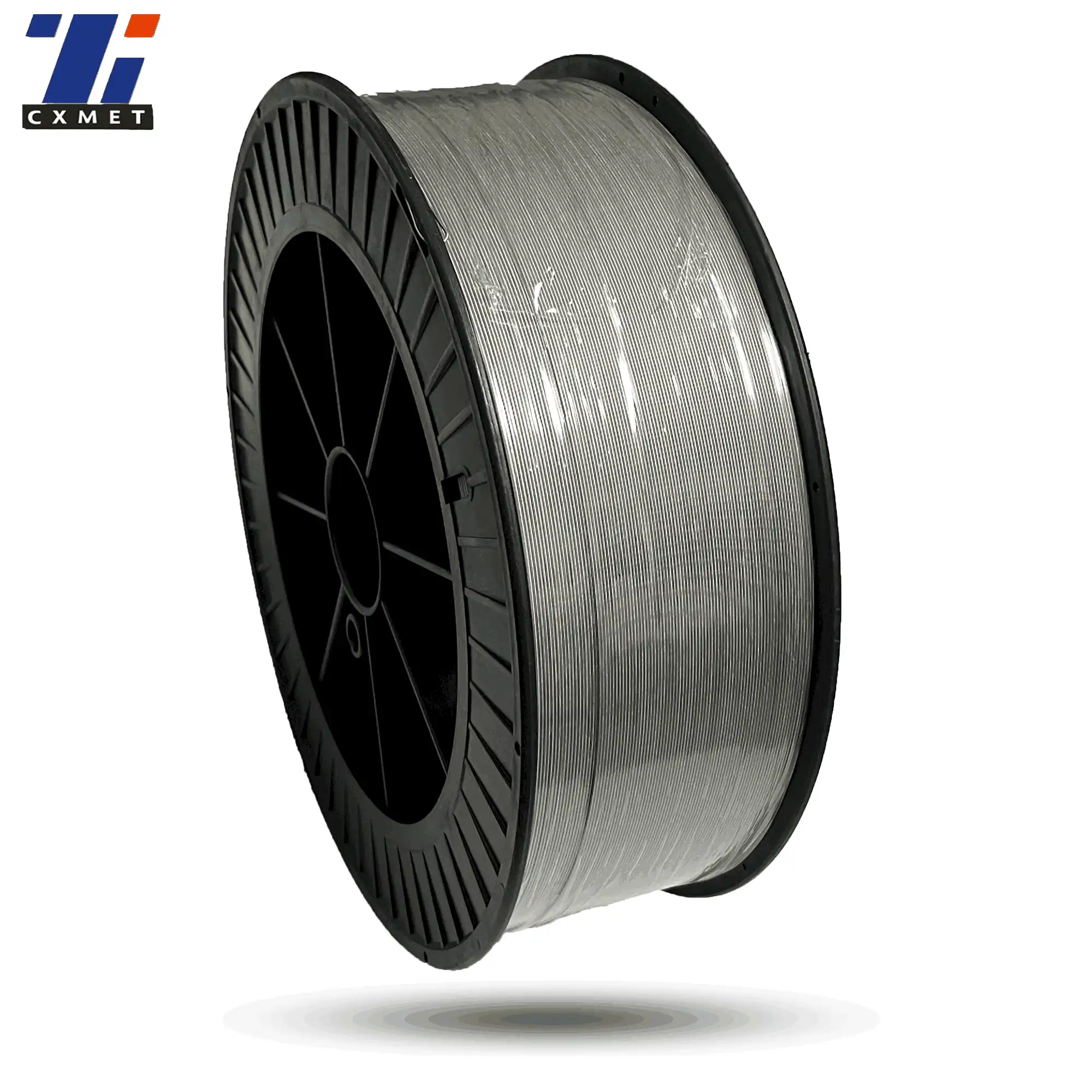

Grade 7 titanium wire, also known as Gr7 titanium wire, has become increasingly popular in medical applications due to its unique properties and numerous benefits. This alloy, composed of titanium with small amounts of palladium, offers exceptional corrosion resistance, biocompatibility, and strength-to-weight ratio. These characteristics make it an ideal choice for various medical devices and implants. In this blog post, we will explore the advantages of using it in medical applications and how it contributes to improved patient outcomes and medical device performance.

How does Gr7 titanium wire enhance biocompatibility in medical implants?

Biocompatibility is a crucial factor in the selection of materials for medical implants and devices. Gr7 titanium wire excels in this aspect, making it an excellent choice for various medical applications. The enhanced biocompatibility of Gr7 titanium wire can be attributed to several factors:

- Corrosion resistance: Gr7 titanium wire exhibits exceptional resistance to corrosion, even in highly aggressive environments such as the human body. This resistance is primarily due to the addition of palladium, which forms a stable passive oxide layer on the surface of the wire. This protective layer prevents the release of metal ions into the surrounding tissues, reducing the risk of adverse reactions and improving overall biocompatibility.

- Low reactivity: Titanium, in general, is known for its low reactivity with human tissues. Gr7 titanium wire takes this property a step further by incorporating palladium, which further reduces the material's reactivity. This low reactivity minimizes the risk of inflammatory responses and allergic reactions, making it suitable for long-term implantation.

- Osseointegration: it promotes excellent osseointegration, which is the direct structural and functional connection between living bone tissue and the surface of an implant. This property is particularly beneficial for orthopedic and dental implants, as it ensures better fixation and long-term stability of the implanted device.

- Reduced bacterial adhesion: The surface properties of Gr7 titanium wire contribute to reduced bacterial adhesion compared to other materials. This characteristic helps minimize the risk of implant-associated infections, which can be a significant concern in medical applications.

The enhanced biocompatibility of Gr7 titanium wire translates to several benefits for patients and healthcare providers:

- Reduced risk of implant rejection and complications

- Improved long-term stability and performance of medical devices

- Lower incidence of inflammatory responses and allergic reactions

- Better integration with surrounding tissues, leading to improved healing and functionality

- Increased patient comfort and satisfaction

These advantages make it an excellent choice for a wide range of medical applications, including cardiovascular devices, orthopedic implants, dental implants, and neurostimulation devices.

What are the mechanical properties of Gr7 titanium wire that make it suitable for medical devices?

The mechanical properties of Gr7 titanium wire play a crucial role in its suitability for medical devices. These properties contribute to the wire's performance, durability, and overall effectiveness in various medical applications. Let's explore the key mechanical properties that make Gr7 titanium wire an excellent choice for medical devices:

- High strength-to-weight ratio: Gr7 titanium wire offers an exceptional strength-to-weight ratio, making it ideal for applications where both strength and lightweight properties are required. This characteristic allows for the creation of strong yet lightweight medical devices, which can be particularly beneficial in implantable devices and minimally invasive surgical instruments.

- Excellent fatigue resistance: Medical devices often undergo repeated stress and strain during their lifespan. Gr7 titanium wire exhibits superior fatigue resistance, enabling it to withstand cyclic loading without premature failure. This property is crucial for applications such as cardiovascular stents, orthopedic implants, and dental implants, where long-term durability is essential.

- Low modulus of elasticity: The relatively low modulus of elasticity of Gr7 titanium wire allows for better stress distribution and reduced stress shielding in implant applications. This property is particularly beneficial in orthopedic implants, as it helps maintain bone density and prevents bone resorption around the implant site.

- Good ductility and formability: Gr7 titanium wire possesses excellent ductility and formability, allowing for easy shaping and manipulation during the manufacturing process. This characteristic enables the creation of complex geometries and intricate designs in medical devices, such as cardiovascular stents and guidewires.

- Resistance to wear and galling: The addition of palladium in it enhances its resistance to wear and galling. This property is crucial for applications involving moving parts or surfaces in contact with other materials, such as joint replacements and dental implants.

- Thermal stability: Gr7 titanium wire maintains its mechanical properties over a wide range of temperatures, including those encountered in the human body. This thermal stability ensures consistent performance and reliability of medical devices throughout their lifespan.

The combination of these mechanical properties makes it suitable for various medical device applications, including:

- Cardiovascular stents and guidewires

- Orthopedic implants and fixation devices

- Dental implants and prosthetics

- Neurostimulation electrodes

- Surgical instruments and tools

- Maxillofacial and craniofacial implants

By leveraging these mechanical properties, medical device manufacturers can create innovative, durable, and effective products that improve patient outcomes and quality of life.

How does Gr7 titanium wire contribute to the longevity and performance of medical implants?

The longevity and performance of medical implants are critical factors in ensuring positive patient outcomes and reducing the need for revision surgeries. Gr7 titanium wire contributes significantly to these aspects, making it a preferred choice for many medical implant applications. Let's explore how it enhances the longevity and performance of medical implants:

- Exceptional corrosion resistance: One of the primary reasons for the longevity of it implants is their outstanding corrosion resistance. The addition of palladium to the titanium alloy creates a highly stable passive oxide layer on the surface, which protects the implant from corrosion in the aggressive environment of the human body. This resistance to corrosion ensures that the implant maintains its structural integrity and functionality over extended periods, reducing the risk of implant failure and the need for replacement.

- Mechanical stability: The excellent mechanical properties of it, including its high strength-to-weight ratio and fatigue resistance, contribute to the long-term stability of medical implants. This stability is crucial for maintaining the implant's position and function within the body, particularly in load-bearing applications such as orthopedic and dental implants. The ability to withstand repeated stress and strain without significant degradation ensures that the implant continues to perform its intended function effectively over time.

- Biocompatibility and reduced inflammatory response: The biocompatibility of it plays a significant role in the longevity of medical implants. By minimizing the risk of adverse reactions and inflammatory responses, Gr7 titanium wire implants are less likely to be rejected by the body or cause complications that could lead to premature failure. This reduced inflammatory response also contributes to better healing and integration of the implant with surrounding tissues, further enhancing its long-term performance.

- Resistance to wear and degradation: In applications where implants are subject to wear, such as joint replacements or dental implants, the resistance of it to wear and degradation is crucial for maintaining long-term performance. This resistance helps preserve the implant's surface integrity and reduces the release of wear particles, which can potentially lead to complications or implant failure over time.

- Osseointegration and tissue attachment: The surface properties of Gr7 titanium wire promote excellent osseointegration and tissue attachment. This strong bond between the implant and surrounding tissues contributes to the implant's stability and longevity. In orthopedic and dental applications, for example, the enhanced osseointegration can lead to better long-term outcomes and reduced risk of implant loosening or failure.

- Resistance to bacterial colonization: The surface properties of Gr7 titanium wire also contribute to reduced bacterial adhesion and colonization. This characteristic is particularly important for implants that are at risk of infection, such as orthopedic implants or cardiovascular devices. By minimizing the risk of implant-associated infections, Gr7 titanium wire helps maintain the implant's performance and reduces the need for revision surgeries due to infection-related complications.

- Compatibility with imaging techniques: it is compatible with various medical imaging techniques, including X-rays, CT scans, and MRI. This compatibility allows for easy post-operative monitoring and evaluation of the implant's position and performance without causing significant artifacts or interference. The ability to accurately assess the implant's condition over time contributes to better long-term management and early detection of any potential issues.

The combination of these factors makes it an excellent choice for medical implants that require long-term performance and reliability. By utilizing it in medical implants, healthcare providers can offer patients solutions that are designed to last, potentially reducing the need for revision surgeries and improving overall quality of life.

In conclusion, the benefits of using Gr7 titanium wire in medical applications are numerous and significant. From its enhanced biocompatibility and excellent mechanical properties to its contribution to the longevity and performance of medical implants, Gr7 titanium wire continues to play a crucial role in advancing medical device technology and improving patient outcomes. As research and development in this field progress, we can expect to see even more innovative applications of Gr7 titanium wire in the medical industry, further enhancing the quality of healthcare and patient experiences.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

- Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the mechanical behavior of biomedical materials, 1(1), 30-42.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.

- Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

- Chen, Q., & Thouas, G. A. (2015). Metallic implant biomaterials. Materials Science and Engineering: R: Reports, 87, 1-57.

- Ratner, B. D., Hoffman, A. S., Schoen, F. J., & Lemons, J. E. (Eds.). (2004). Biomaterials science: an introduction to materials in medicine. Elsevier.

- Brånemark, P. I., Hansson, B. O., Adell, R., Breine, U., Lindström, J., Hallén, O., & Öhman, A. (1977). Osseointegrated implants in the treatment of the edentulous jaw. Experience from a 10-year period. Scandinavian journal of plastic and reconstructive surgery. Supplementum, 16, 1-132.

- Pohler, O. E. (2000). Unalloyed titanium for implants in bone surgery. Injury, 31, D7-D13.

- Wang, K. (1996). The use of titanium for medical applications in the USA. Materials Science and Engineering: A, 213(1-2), 134-137.

- Long, M., & Rack, H. J. (1998). Titanium alloys in total joint replacement—a materials science perspective. Biomaterials, 19(18), 1621-1639.