- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Industries Use Grade 2 Titanium Round Bars?

2024-09-13 16:55:59

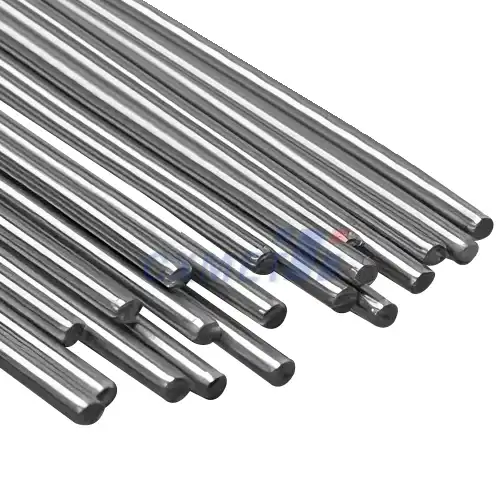

Grade 2 titanium round bars are versatile and widely used materials in various industries due to their exceptional properties. These bars combine the strength of titanium with excellent corrosion resistance, making them suitable for a wide range of applications. In this blog post, we'll explore the industries that rely on Grade 2 titanium round bars and delve into some frequently asked questions about this remarkable material.

What are the main properties of Grade 2 titanium round bars?

Grade 2 titanium, also known as commercially pure (CP) titanium, is renowned for its outstanding combination of properties that make it an ideal choice for numerous industrial applications. The round bar form factor adds to its versatility, allowing for easy machining and fabrication into various components.

Key properties of Grade 2 titanium round bars include:

1. Excellent corrosion resistance: Grade 2 titanium is highly resistant to corrosion in various environments, including saltwater, acids, and industrial chemicals. This property is attributed to the formation of a stable, protective oxide layer on the surface of the metal when exposed to oxygen.

2. High strength-to-weight ratio: While not as strong as some titanium alloys, Grade 2 titanium still offers an impressive strength-to-weight ratio. This makes it an excellent choice for applications where weight reduction is crucial without compromising structural integrity.

3. Low density: Titanium is approximately 45% lighter than steel and 60% heavier than aluminum. This low density contributes to its high strength-to-weight ratio and makes it ideal for weight-sensitive applications.

4. Biocompatibility: Grade 2 titanium is highly biocompatible, meaning it can be safely used in medical and dental applications without causing adverse reactions in the human body.

5. Excellent formability: The round bar form of Grade 2 titanium allows for easy machining, welding, and forming into various shapes and components.

6. Wide temperature range: Grade 2 titanium maintains its properties over a broad temperature range, from cryogenic temperatures to moderately high temperatures (up to about 300°C or 572°F).

7. Non-magnetic properties: Grade 2 titanium is non-magnetic, making it suitable for applications where magnetic interference must be avoided.

These properties make Grade 2 titanium round bars an excellent choice for industries that require materials with high performance in challenging environments, such as marine, chemical processing, and aerospace sectors.

How are Grade 2 titanium round bars used in the aerospace industry?

The aerospace industry is one of the primary consumers of Grade 2 titanium round bars, utilizing their unique properties to enhance aircraft performance and reliability. The combination of high strength, low density, and excellent corrosion resistance makes these bars invaluable in various aerospace applications.

1. Structural components: Grade 2 titanium round bars are used to manufacture various structural components in aircraft, such as brackets, fittings, and fasteners. These parts benefit from titanium's high strength-to-weight ratio, which helps reduce the overall weight of the aircraft while maintaining structural integrity.

2. Engine components: Although not used in the most critical high-temperature areas of jet engines (where more advanced titanium alloys are employed), Grade 2 titanium round bars find applications in less demanding engine parts. They are used in compressor blades, hydraulic systems, and other components that require corrosion resistance and moderate strength.

3. Landing gear components: The excellent fatigue resistance and corrosion resistance of Grade 2 titanium make it suitable for certain landing gear components. These parts are subjected to repeated stress cycles and exposure to various environmental conditions, making titanium an ideal choice.

4. Hydraulic and pneumatic systems: Grade 2 titanium round bars are used to manufacture tubing and fittings for hydraulic and pneumatic systems in aircraft. The material's corrosion resistance and compatibility with hydraulic fluids make it an excellent choice for these applications.

5. Fasteners and bolts: Titanium fasteners and bolts made from Grade 2 round bars are used in areas where corrosion resistance and weight reduction are critical. These fasteners offer excellent strength and durability while helping to minimize the overall weight of the aircraft.

6. Interior components: Some interior components of aircraft, such as seat frames or galley equipment, may utilize Grade 2 titanium round bars in their construction. The material's low density contributes to weight reduction efforts, which is crucial for fuel efficiency.

7. Rocket and spacecraft components: Beyond aircraft, Grade 2 titanium round bars are also used in the space industry for various components in rockets and spacecraft. The material's high strength-to-weight ratio and corrosion resistance make it valuable for both structural and functional parts in space applications.

8. Prototype and testing components: Due to its excellent machinability, Grade 2 titanium round bars are often used to create prototype parts or components for testing purposes in aerospace research and development.

The use of Grade 2 titanium round bars in the aerospace industry contributes significantly to the overall performance, efficiency, and safety of aircraft and spacecraft. By leveraging the material's unique properties, aerospace engineers can design lighter, more durable, and corrosion-resistant components that withstand the demanding conditions of flight and space travel.

What role do Grade 2 titanium round bars play in the marine industry?

The marine industry is another significant user of Grade 2 titanium round bars, taking advantage of the material's exceptional corrosion resistance and durability in saltwater environments. The harsh conditions at sea, including exposure to saltwater, marine organisms, and varying temperatures, make Grade 2 titanium an ideal choice for numerous marine applications.

1. Propulsion systems: Grade 2 titanium round bars are used in the manufacturing of various components in marine propulsion systems. This includes propeller shafts, impellers, and pump components. The material's resistance to saltwater corrosion and its high strength-to-weight ratio contribute to the longevity and efficiency of these critical parts.

2. Heat exchangers: Marine heat exchangers, particularly those used in desalination plants or offshore platforms, often incorporate Grade 2 titanium components. The material's excellent resistance to both seawater and the chemicals used in desalination processes makes it an ideal choice for tubing and other heat exchanger parts.

3. Offshore oil and gas equipment: The offshore oil and gas industry relies heavily on Grade 2 titanium round bars for various applications. These include subsea valves, fittings, and piping systems that are exposed to corrosive seawater and harsh chemicals. The material's durability in these environments helps extend the lifespan of critical equipment and reduce maintenance costs.

4. Marine fittings and fasteners: Grade 2 titanium is used to manufacture various marine fittings and fasteners, including bolts, nuts, and washers. These components benefit from titanium's corrosion resistance and strength, ensuring long-lasting and reliable connections in marine structures and equipment.

5. Underwater remotely operated vehicles (ROVs): ROVs used for underwater exploration, maintenance, and research often incorporate Grade 2 titanium components. The material's low density and corrosion resistance make it ideal for ROV frames, housings, and other structural elements.

6. Submersibles and diving equipment: Grade 2 titanium round bars are used in the construction of submersibles and diving equipment. The material's high strength-to-weight ratio and biocompatibility make it suitable for pressure hulls, air tanks, and other components that need to withstand high pressures and prolonged exposure to seawater.

7. Desalination plants: In addition to heat exchangers, Grade 2 titanium is used in other components of desalination plants, such as piping systems and valves. Its resistance to both seawater and the chemicals used in the desalination process contributes to the longevity and efficiency of these facilities.

8. Marine research equipment: Oceanographic research equipment, including sampling devices, sensors, and monitoring systems, often incorporates Grade 2 titanium components. The material's corrosion resistance and non-magnetic properties make it ideal for applications where data accuracy and long-term reliability are crucial.

9. Boat and ship fittings: Various fittings and hardware on boats and ships, particularly in high-end or performance vessels, may be made from Grade 2 titanium. This includes cleats, railings, and other deck hardware that benefit from the material's corrosion resistance and aesthetic appeal.

10. Marine energy systems: Emerging technologies in marine energy, such as tidal and wave energy converters, often utilize Grade 2 titanium components. The material's ability to withstand the corrosive and high-stress environments associated with these applications makes it a valuable choice for various structural and mechanical components.

The use of Grade 2 titanium round bars in the marine industry has revolutionized the design and longevity of numerous marine applications. By leveraging the material's exceptional corrosion resistance, high strength-to-weight ratio, and durability, marine engineers and designers can create components and systems that withstand the challenging conditions at sea while offering improved performance and reduced maintenance requirements.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

1. Titanium Processing Center. (2023). Grade 2 Titanium.

2. AZoM. (2021). Grade 2 Titanium: Properties, Processing, and Applications.

3. Titanium Industries. (2023). Titanium Grade 2.

4. United Performance Metals. (2023). Titanium Grade 2.

5. Aerospace Specification Metals Inc. (2023). Titanium Ti-2 Properties.

6. ASTM International. (2021). ASTM B348 - Standard Specification for Titanium and Titanium Alloy Bars and Billets.

7. TWI Ltd. (2022). Titanium and Its Alloys - Types and Applications.

8. MatWeb. (2023). Titanium Grade 2 (UNS R50400).

9. TMS Titanium. (2023). Grade 2 Titanium.

10. Specialty Metals. (2023). Titanium Grade 2.

.webp)