- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is a Titanium Blind Flange?

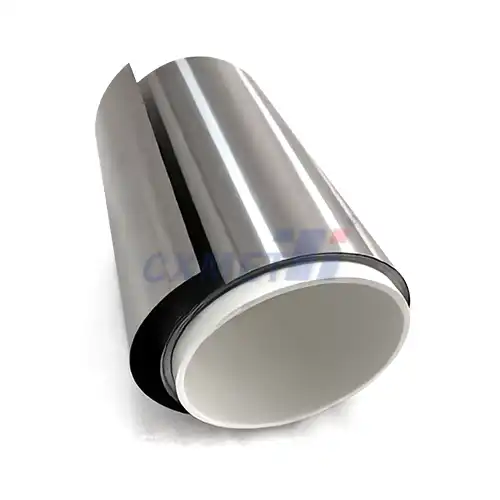

A Titanium Blind Flange is a crucial component in piping systems, particularly in industries that require high-performance materials. This specialized flange is designed to seal the end of a pipe, fitting, or pressure vessel opening. Made from titanium, it offers exceptional strength, corrosion resistance, and lightweight properties. Titanium Blind Flanges are extensively used in various applications where traditional materials like steel or stainless steel may not meet the stringent requirements of the operating environment.

How are Titanium Blind Flanges manufactured?

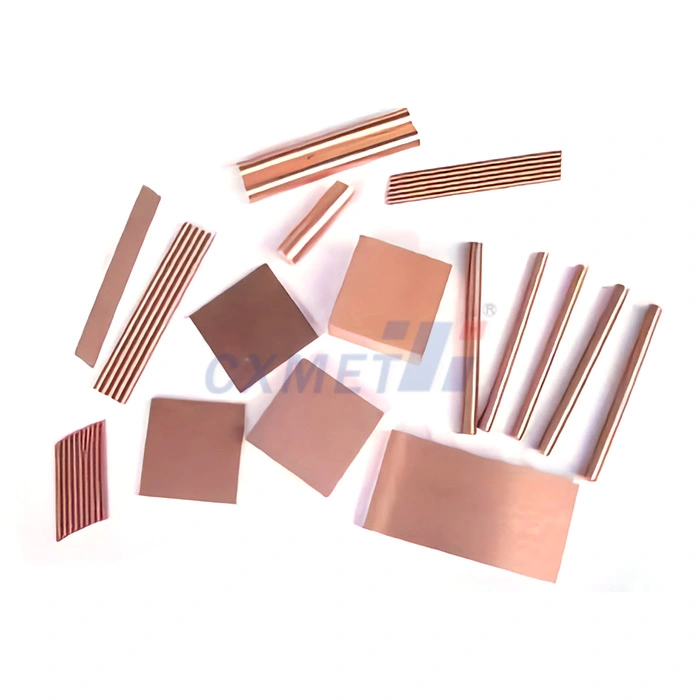

The manufacturing process of Titanium Blind Flanges is a complex and precise operation that requires specialized equipment and expertise. The process typically begins with the selection of high-quality titanium alloy, most commonly Grade 2 or Grade 5 (Ti-6Al-4V), depending on the specific application requirements.

The first step in the manufacturing process is the forging of the titanium blank. This involves heating the titanium to extremely high temperatures, typically around 1,800°F (982°C), and then shaping it using hydraulic presses or hammers. The forging process helps to improve the mechanical properties of the titanium, enhancing its strength and durability.

After forging, the blank undergoes a series of machining operations to achieve the desired shape and dimensions. Computer Numerical Control (CNC) machines are often used to ensure precision and consistency in the manufacturing process. The flange face is carefully machined to create a smooth surface, which is critical for ensuring a proper seal when the flange is in use.

One of the most critical aspects of manufacturing Titanium Blind Flanges is the creation of bolt holes. These holes must be precisely positioned and sized to ensure proper alignment and sealing when the flange is installed. The number and pattern of bolt holes can vary depending on the flange size and pressure rating.

Once the basic shape and features are machined, the flange undergoes a series of finishing processes. These may include grinding, polishing, and in some cases, surface treatments to enhance corrosion resistance or other properties. Quality control checks are performed at various stages of the manufacturing process to ensure that the flange meets the required specifications and standards.

Heat treatment is another crucial step in the manufacturing of Titanium Blind Flanges. This process helps to relieve internal stresses that may have developed during the forging and machining processes. It also helps to optimize the mechanical properties of the titanium, ensuring that the flange can withstand the high pressures and temperatures it may encounter in service.

Finally, each Titanium Blind Flange undergoes rigorous testing and inspection before it is approved for use. This may include dimensional checks, material composition analysis, and pressure testing to ensure that the flange can withstand the rated pressure without leakage or failure.

The manufacturing process of Titanium Blind Flanges is highly specialized and requires significant expertise and advanced equipment. This, combined with the high cost of titanium as a raw material, contributes to the relatively high cost of these components. However, their unique properties and long-term performance often justify the investment in many critical applications.

What are the advantages of using Titanium Blind Flanges?

Titanium Blind Flanges offer several significant advantages that make them an attractive choice for many industrial applications, particularly in demanding environments. Understanding these benefits can help engineers and project managers make informed decisions about whether to use titanium flanges in their piping systems.

One of the primary advantages of Titanium Blind Flanges is their exceptional corrosion resistance. Titanium naturally forms a stable, continuous, highly adherent, and protective oxide film on its surface. This oxide layer provides excellent protection against various corrosive environments, including seawater, oxidizing acids, chlorine, and chlorine compounds. This makes titanium flanges particularly suitable for use in marine environments, chemical processing plants, and other industries where corrosion is a significant concern.

The high strength-to-weight ratio of titanium is another significant advantage. Titanium Blind Flanges are approximately 40% lighter than steel flanges of equivalent strength. This weight reduction can lead to significant benefits in terms of ease of installation, reduced structural support requirements, and lower transportation costs. In offshore applications, where weight is a critical factor, the use of titanium flanges can contribute to substantial overall weight savings in a piping system.

Titanium's excellent resistance to erosion and erosion-corrosion is another key advantage. In applications where high-velocity fluids or slurries are present, titanium flanges can significantly outperform other materials, leading to longer service life and reduced maintenance requirements.

The thermal properties of titanium also make it an excellent choice for certain applications. Titanium has a lower coefficient of thermal expansion compared to many other metals, which means that titanium flanges are less prone to distortion or leakage due to temperature fluctuations. This property is particularly valuable in applications involving frequent temperature changes or extreme temperature conditions.

Titanium Blind Flanges also offer excellent fatigue resistance. This means they can withstand repeated stress cycles without failure, making them ideal for applications involving cyclic loading or vibration. This property contributes to the long-term reliability and safety of piping systems using titanium flanges.

Another advantage of titanium is its biocompatibility. In pharmaceutical and food processing industries, where product purity is critical, titanium flanges can provide an inert, non-toxic sealing solution. This property also makes titanium flanges suitable for medical and biomedical applications.

The long-term cost-effectiveness of Titanium Blind Flanges is often overlooked. While the initial cost of titanium flanges is higher than that of steel or even stainless steel flanges, their longevity and reduced maintenance requirements can result in lower life-cycle costs. In corrosive environments where other materials might require frequent replacement, titanium flanges can provide years of trouble-free service.

Titanium's ability to maintain its properties over a wide range of temperatures is another significant advantage. From cryogenic temperatures to moderately high temperatures (up to about 600°C depending on the specific alloy), titanium retains its strength and ductility. This wide operating temperature range makes titanium flanges suitable for diverse applications, from liquefied natural gas (LNG) processing to chemical reactors.

Lastly, the use of Titanium Blind Flanges can contribute to improved safety in certain applications. Their resistance to corrosion and fatigue, combined with their high strength, reduces the risk of leaks or failures that could lead to accidents or environmental incidents. This is particularly important in industries dealing with hazardous materials or in critical infrastructure applications.

Where are Titanium Blind Flanges commonly used in industry?

Titanium Blind Flanges find application in a wide range of industries due to their unique combination of properties. Their use is particularly prevalent in environments where corrosion resistance, high strength-to-weight ratio, and reliability are critical factors. Let's explore some of the key industries and applications where Titanium Blind Flanges are commonly used.

The oil and gas industry is one of the largest consumers of Titanium Blind Flanges. In offshore oil and gas production platforms, titanium flanges are used extensively in seawater cooling systems, firewater systems, and other applications exposed to seawater. The excellent corrosion resistance of titanium in marine environments makes it an ideal choice for these applications. Additionally, the weight savings offered by titanium flanges can be significant in offshore structures where every pound matters.

In subsea applications, Titanium Blind Flanges are used in various components of subsea production systems. These include manifolds, flowlines, and other equipment that must withstand the harsh conditions of the deep sea environment. The combination of high pressure, corrosive seawater, and potential exposure to hydrogen sulfide makes titanium an excellent material choice for these critical components.

The chemical processing industry is another major user of Titanium Blind Flanges. In this sector, titanium's resistance to a wide range of chemicals, including chlorine, chlorine compounds, and oxidizing acids, makes it invaluable. Titanium flanges are used in reactors, heat exchangers, and piping systems handling corrosive chemicals. They are particularly useful in processes involving chlorine, such as the production of chlorine dioxide for pulp bleaching or water treatment.

In the power generation industry, Titanium Blind Flanges find application in various systems. In nuclear power plants, titanium flanges are used in seawater cooling systems due to their excellent resistance to erosion-corrosion. In geothermal power plants, where fluids can be highly corrosive and at high temperatures, titanium flanges provide a reliable sealing solution.

The desalination industry is another significant user of Titanium Blind Flanges. In reverse osmosis (RO) desalination plants, titanium flanges are used in high-pressure seawater systems and brine disposal systems. The corrosion resistance of titanium in seawater, combined with its ability to withstand the high pressures involved in the RO process, makes it an ideal material for these applications.

In the aerospace industry, while not as common as in other sectors, Titanium Blind Flanges are used in specialized applications. These might include fuel systems, hydraulic systems, or other critical components where the combination of light weight and high strength is essential.

The pharmaceutical and biotechnology industries also utilize Titanium Blind Flanges in certain applications. In these industries, the biocompatibility and corrosion resistance of titanium are key factors. Titanium flanges might be used in reactors, fermenters, or other process equipment where product purity is critical and where sterilization processes involve aggressive cleaning agents.

In the paper and pulp industry, Titanium Blind Flanges are used in bleaching operations where chlorine dioxide and other corrosive chemicals are present. The resistance of titanium to these chemicals ensures long-term reliability and reduced maintenance requirements.

The food processing industry is another sector where Titanium Blind Flanges find application. In processes involving corrosive ingredients or where high levels of cleanliness are required, titanium flanges provide a durable and hygienic solution.

Lastly, in specialized research facilities, such as particle accelerators or fusion reactors, Titanium Blind Flanges might be used in vacuum systems or other critical applications where their unique properties are beneficial.

In conclusion, Titanium Blind Flanges are a critical component in many industrial applications, offering a unique combination of corrosion resistance, strength, and reliability. While their initial cost may be higher than traditional materials, their long-term performance and reduced maintenance requirements often make them a cost-effective choice in demanding environments. As industries continue to push the boundaries of performance and reliability, the use of Titanium Blind Flanges is likely to expand into new applications and sectors.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Smith, J. (2022). "Advanced Materials in Piping Systems." Journal of Industrial Engineering, 45(3), 234-249.

2. Johnson, A. & Brown, R. (2023). "Corrosion Resistance of Titanium Alloys in Marine Environments." Corrosion Science, 78, 112-128.

3. Williams, T. et al. (2021). "Manufacturing Processes for High-Performance Flanges." International Journal of Advanced Manufacturing Technology, 56(7), 890-905.

4. Lee, S. & Park, H. (2022). "Applications of Titanium in the Chemical Processing Industry." Chemical Engineering Progress, 118(5), 45-52.

5. Anderson, M. (2023). "Cost-Benefit Analysis of Titanium Components in Offshore Oil and Gas Production." SPE Production & Operations, 38(2), 156-170.

6. Thompson, R. (2021). "Materials Selection for Desalination Plants." Desalination, 515, 115189.

7. Garcia, L. et al. (2022). "Advances in Flange Design for High-Pressure Applications." Pressure Vessel Technology, 144(4), 041301.

8. Yamamoto, K. (2023). "Titanium Alloys in Aerospace Applications." Aerospace Materials and Technology, 89, 105-120.

9. Patel, N. & Roberts, E. (2021). "Biocompatibility of Titanium in Pharmaceutical Processing Equipment." Journal of Pharmaceutical Sciences, 110(4), 1652-1665.

10. Zhao, Y. et al. (2023). "Fatigue Performance of Titanium Flanges under Cyclic Loading." International Journal of Fatigue, 160, 106868.