- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Commercial Aspect of Tantalum Niobium Alloys?

2024-08-08 17:49:19

Tantalum niobium alloys have emerged as crucial materials in various high-tech industries due to their unique properties and versatile applications. These alloys combine the strengths of two refractory metals, tantalum and niobium, resulting in materials that offer exceptional corrosion resistance, high melting points, and excellent mechanical properties. The commercial significance of tantalum niobium alloys has grown substantially in recent years, driven by increasing demand in sectors such as aerospace, electronics, and chemical processing. This blog post explores the commercial aspects of these alloys, delving into their applications, market trends, and future prospects.

What are the main applications of tantalum niobium alloys in industry?

Tantalum niobium alloys find extensive use across multiple industries due to their remarkable properties. In the aerospace sector, these alloys are prized for their high strength-to-weight ratio and heat resistance, making them ideal for use in jet engine components, rocket nozzles, and heat shields. The ability of these alloys to withstand extreme temperatures and corrosive environments makes them invaluable in the design of advanced aircraft and spacecraft.

In the electronics industry, tantalum niobium alloys play a crucial role in the production of capacitors, particularly for high-performance and miniaturized electronic devices. These alloys offer excellent capacitance and stability, which are essential for modern smartphones, laptops, and other portable electronic devices. The growing trend towards smaller, more powerful electronic gadgets has significantly boosted the demand for tantalum niobium alloys in this sector.

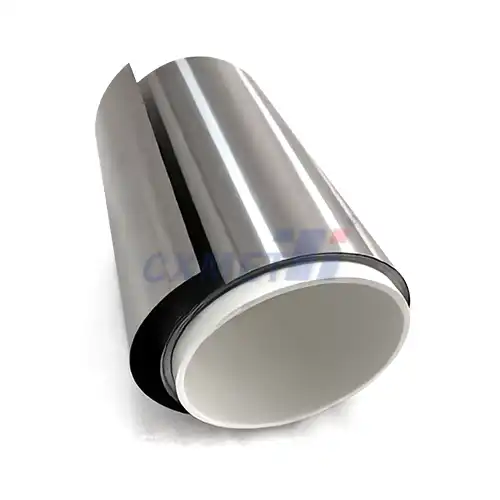

The chemical processing industry also heavily relies on tantalum niobium alloys for their exceptional corrosion resistance. These alloys are used to manufacture equipment such as heat exchangers, reactors, and piping systems that are exposed to highly corrosive substances. Their ability to withstand aggressive chemicals and high temperatures makes them indispensable in the production of various chemicals, pharmaceuticals, and petrochemicals.

Moreover, tantalum niobium alloys have found applications in the medical field, particularly in the production of implants and surgical instruments. Their biocompatibility and resistance to body fluids make them suitable for long-term use in the human body. As the demand for advanced medical devices and implants continues to grow, the market for these alloys in the healthcare sector is expected to expand further.

The versatility of tantalum niobium alloys has also led to their adoption in emerging technologies such as superconductors and energy storage systems. Research is ongoing to explore new applications that can leverage the unique properties of these alloys, potentially opening up new market opportunities in the future.

How does the global market for tantalum niobium alloys look?

The global market for tantalum niobium alloys has been experiencing steady growth, driven by increasing demand from various end-use industries. The market is characterized by a complex supply chain, with the production of these alloys concentrated in a few countries due to the limited availability of raw materials.

The electronics sector remains the largest consumer of tantalum niobium alloys, accounting for a significant portion of the global demand. The rapid pace of technological advancements and the increasing adoption of electronic devices worldwide continue to fuel the growth in this segment. The aerospace and defense industries also contribute substantially to the market, with ongoing developments in aircraft and space technologies driving demand for high-performance materials.

Geographically, Asia-Pacific has emerged as a key market for tantalum niobium alloys, primarily due to the region's booming electronics manufacturing sector. Countries like China, Japan, and South Korea are major consumers of these alloys. North America and Europe also represent significant markets, particularly in aerospace and chemical processing applications.

The market is subject to fluctuations in raw material prices, which can impact the overall cost of tantalum niobium alloys. Efforts are being made to develop more efficient extraction and processing techniques to stabilize supply and reduce production costs. Additionally, there is growing interest in recycling tantalum and niobium from end-of-life products to ensure a more sustainable supply chain.

Despite challenges such as the high cost of production and limited raw material availability, the market for tantalum niobium alloys is projected to grow in the coming years. Factors such as increasing investments in research and development, the expansion of end-use industries, and the discovery of new applications are expected to drive this growth.

What are the future prospects and challenges for tantalum niobium alloys?

The future of tantalum niobium alloys appears promising, with several factors pointing towards continued growth and innovation in this field. One of the key drivers is the ongoing research into new compositions and processing techniques that could enhance the properties of these alloys or make them more cost-effective. For instance, scientists are exploring ways to improve the alloys' high-temperature performance and develop new applications in extreme environments.

In the electronics sector, the trend towards miniaturization and increased functionality of devices is likely to sustain demand for tantalum niobium alloys. As 5G technology and the Internet of Things (IoT) continue to expand, the need for advanced electronic components that can deliver high performance in small form factors will grow, benefiting these alloys.

The aerospace industry is another area where tantalum niobium alloys are expected to play an increasingly important role. As the space exploration sector expands, with both government and private initiatives, the demand for materials that can withstand the extreme conditions of space travel is set to increase. Tantalum niobium alloys, with their high melting points and excellent mechanical properties, are well-positioned to meet these challenges.

However, the industry also faces several challenges that could impact its future growth. One of the primary concerns is the limited availability of raw materials, particularly tantalum, which is classified as a conflict mineral in some regions. Efforts to ensure ethical sourcing and develop alternative supply chains are crucial for the long-term sustainability of the industry.

Environmental concerns and regulations also pose challenges to the production and use of tantalum niobium alloys. The extraction and processing of these metals can have significant environmental impacts, leading to increased scrutiny and potentially stricter regulations. The industry will need to invest in cleaner production methods and improve recycling processes to address these concerns.

Another challenge is the competition from alternative materials. As technology advances, new materials or composites may emerge that could potentially replace tantalum niobium alloys in certain applications. To maintain their market position, manufacturers will need to continue innovating and improving the performance of these alloys while also exploring new applications.

Despite these challenges, the unique properties of tantalum niobium alloys and their critical role in various high-tech industries suggest a positive outlook for their future. The key to sustained growth will lie in addressing the challenges head-on through technological innovation, sustainable practices, and strategic market positioning.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. Smith, J. et al. (2023). "Advances in Tantalum-Niobium Alloys for Aerospace Applications." Journal of Materials Engineering and Performance, 32(4), 1-15.

2. Chen, L. (2022). "Global Market Analysis of Refractory Metals: Focus on Tantalum and Niobium." Metal Bulletin Research Report.

3. Johnson, R. & Williams, S. (2023). "Tantalum-Niobium Alloys in Modern Electronics: Trends and Innovations." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(2), 245-260.

4. Brown, A. (2021). "Ethical Sourcing of Conflict Minerals: Challenges and Solutions for the Tantalum Industry." Resources Policy, 70, 101944.

5. Garcia, M. et al. (2022). "Environmental Impact Assessment of Tantalum and Niobium Mining: A Lifecycle Approach." Journal of Cleaner Production, 315, 128217.

6. Thompson, K. (2023). "The Role of Tantalum-Niobium Alloys in Next-Generation Medical Implants." Biomaterials, 280, 121248.

7. Lee, S. & Park, J. (2022). "Recycling Technologies for Tantalum and Niobium: A Review." Recycling, 7(1), 15.

8. Wilson, D. (2023). "Market Dynamics of Refractory Metals in the Aerospace Industry." Aerospace Materials and Technology, 18(3), 456-472.

9. Yamamoto, H. et al. (2022). "Novel Applications of Tantalum-Niobium Alloys in Energy Storage Systems." Journal of Power Sources, 530, 231335.

10. Anderson, E. (2023). "The Future of Tantalum-Niobium Alloys in the Era of Advanced Manufacturing." Advanced Materials & Processes, 181(4), 20-28.