- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Connection Method for Titanium Socket Weld Flanges?

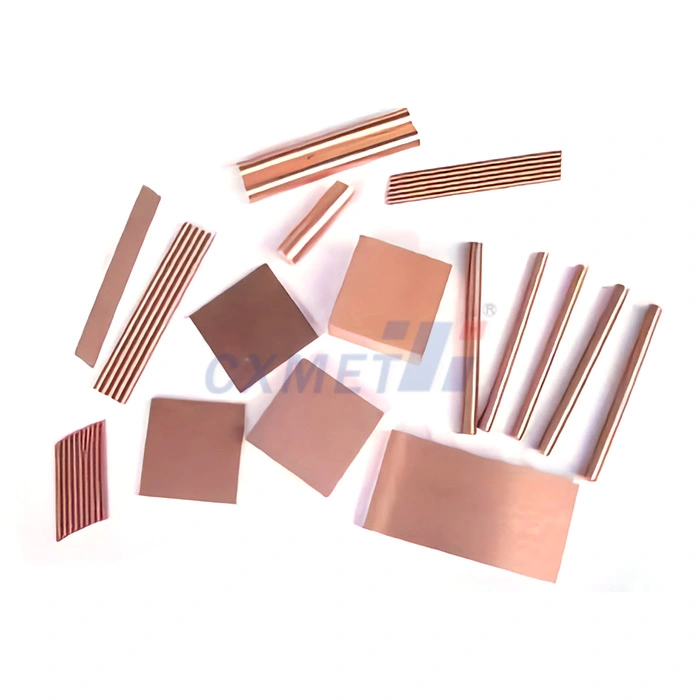

Titanium socket weld flanges are crucial components in various industrial applications, particularly in sectors that require high corrosion resistance and strength-to-weight ratio. The connection method for these flanges is a critical aspect of their installation and performance. Socket welding is the primary technique used to join titanium socket weld flanges to pipes or other components. This method involves inserting the pipe into the socket of the flange and then welding around the circumference to create a strong, leak-proof connection. Understanding the proper connection method is essential for ensuring the integrity and longevity of systems utilizing titanium socket weld flanges.

How are titanium socket weld flanges different from other flange types?

Titanium socket weld flanges stand out from other flange types due to their unique material properties and connection method. Unlike traditional flanges made from materials such as stainless steel or carbon steel, titanium flanges offer exceptional corrosion resistance, high strength-to-weight ratio, and excellent performance in extreme temperatures. This makes them ideal for use in demanding environments, such as chemical processing plants, offshore oil and gas facilities, and aerospace applications.

The socket weld design of these flanges is another distinguishing feature. Unlike slip-on or threaded flanges, socket weld flanges have a recessed area or "socket" into which the pipe is inserted before welding. This design provides several advantages:

1. Enhanced strength: The socket design creates a stronger joint by increasing the weld area and providing better stress distribution.

2. Improved alignment: The socket helps ensure proper alignment between the pipe and flange, reducing the risk of misalignment during installation.

3. Better leak resistance: The welded connection offers superior leak resistance compared to other connection methods, making it suitable for high-pressure applications.

4. Smooth internal bore: The socket weld design results in a smooth internal bore, which reduces turbulence and pressure drop in the system.

5. Compact design: Socket weld flanges typically have a more compact profile compared to other flange types, making them suitable for applications with space constraints.

Furthermore, titanium socket weld flanges are often preferred in applications where weight reduction is critical, such as in aerospace or offshore platforms. The lightweight nature of titanium, combined with its high strength, allows for the design of more efficient and cost-effective systems.

It's important to note that while titanium socket weld flanges offer numerous advantages, they also require specialized welding techniques and equipment due to titanium's reactivity at high temperatures. This necessitates careful consideration of the installation process and the use of skilled welders familiar with titanium welding procedures.

What are the advantages of using titanium socket weld flanges in piping systems?

The use of titanium socket weld flanges in piping systems offers a multitude of advantages that make them an attractive option for various industries. These benefits stem from the inherent properties of titanium as a material and the specific design of socket weld flanges.

1. Corrosion Resistance: One of the primary advantages of titanium socket weld flanges is their exceptional corrosion resistance. Titanium forms a stable, protective oxide layer on its surface when exposed to air or moisture, making it highly resistant to corrosion in aggressive environments. This property is particularly valuable in industries such as chemical processing, oil and gas, and marine applications, where exposure to corrosive substances is common. The use of titanium flanges can significantly extend the lifespan of piping systems and reduce maintenance costs associated with corrosion-related issues.

2. High Strength-to-Weight Ratio: Titanium boasts an impressive strength-to-weight ratio, making it an ideal material for applications where weight reduction is crucial without compromising structural integrity. This characteristic is particularly beneficial in aerospace, offshore platforms, and other weight-sensitive industries. The use of titanium socket weld flanges can contribute to overall system weight reduction, leading to improved fuel efficiency in transportation applications or reduced structural load in stationary installations.

3. Temperature Resistance: Titanium socket weld flanges maintain their mechanical properties over a wide range of temperatures. They perform exceptionally well in both cryogenic conditions and elevated temperatures, making them suitable for diverse applications. This temperature stability ensures consistent performance and reduces the risk of thermal expansion-related issues in piping systems.

4. Biocompatibility: In industries such as pharmaceuticals and food processing, the biocompatibility of materials is crucial. Titanium is known for its excellent biocompatibility, making titanium socket weld flanges a safe choice for applications where material contact with biological substances or food products is a concern.

5. Low Thermal Expansion: Titanium has a relatively low coefficient of thermal expansion compared to many other metals. This property minimizes stress on the piping system due to temperature fluctuations, reducing the risk of leaks or joint failures in applications with significant temperature variations.

6. Leak-Tight Connections: The socket weld design of these flanges, combined with proper welding techniques, results in highly leak-resistant connections. This is particularly important in high-pressure systems or applications where even minor leaks can have significant consequences.

7. Smooth Flow Characteristics: The smooth internal bore created by the socket weld design helps reduce turbulence and pressure drop within the piping system. This can lead to improved flow characteristics and energy efficiency in fluid transport applications.

8. Long-Term Cost-Effectiveness: While the initial cost of titanium socket weld flanges may be higher than that of flanges made from more common materials, their longevity and reduced maintenance requirements often result in lower total lifecycle costs. This makes them a cost-effective choice for long-term installations, particularly in harsh environments.

9. Resistance to Erosion and Abrasion: Titanium exhibits good resistance to erosion and abrasion, making titanium socket weld flanges suitable for applications involving the transport of abrasive materials or high-velocity fluids.

10. Customization Potential: Titanium is relatively easy to machine and form, allowing for the production of custom socket weld flanges to meet specific application requirements. This flexibility in design and manufacturing can be advantageous for unique or specialized piping systems.

While these advantages make titanium socket weld flanges an excellent choice for many applications, it's important to consider factors such as the higher material cost, specialized welding requirements, and potential galvanic corrosion issues when used in conjunction with dissimilar metals. Proper design, installation, and maintenance practices are crucial to fully leverage the benefits of titanium socket weld flanges in piping systems.

What are the best practices for installing titanium socket weld flanges?

Installing titanium socket weld flanges requires careful attention to detail and adherence to best practices to ensure optimal performance and longevity of the piping system. The unique properties of titanium and the specific requirements of socket welding necessitate a specialized approach. Here are the best practices for installing titanium socket weld flanges:

1. Material Preparation:

- Ensure that all materials, including the titanium flange, pipe, and welding consumables, are clean and free from contaminants.

- Use dedicated tools and equipment for titanium to prevent cross-contamination with other metals.

- Store titanium components in a clean, dry area to prevent surface oxidation or contamination.

2. Pipe Preparation:

- Cut the pipe square and remove any burrs or rough edges.

- Clean the pipe end thoroughly, removing any dirt, oil, or debris.

- Ensure that the pipe outside diameter matches the socket inner diameter within the specified tolerance.

3. Flange Preparation:

- Inspect the flange for any defects or damage.

- Clean the socket thoroughly, removing any debris or contaminants.

- Verify that the flange rating and dimensions are appropriate for the intended application.

4. Fit-Up:

- Insert the pipe into the flange socket, ensuring a proper fit.

- Allow for the recommended gap between the pipe end and the socket bottom to accommodate thermal expansion during welding.

- Use alignment tools if necessary to ensure proper positioning of the pipe and flange.

5. Welding Environment:

- Perform welding in a clean, controlled environment to minimize the risk of contamination.

- Use inert gas shielding (typically argon) to protect the weld area from atmospheric contamination.

- Maintain proper ventilation to remove welding fumes and prevent overheating of the work area.

6. Welding Technique:

- Use a qualified welder experienced in titanium welding.

- Employ the Gas Tungsten Arc Welding (GTAW) process, also known as TIG welding, which is most suitable for titanium.

- Maintain a consistent arc length and travel speed to ensure uniform weld penetration.

- Use the appropriate filler metal compatible with the titanium grade of the flange and pipe.

7. Shielding:

- Implement comprehensive shielding techniques to protect the weld area and adjacent surfaces from atmospheric contamination.

- Use trailing shields or purge chambers to maintain inert gas coverage until the weld cools below the reactive temperature.

- Monitor and maintain proper gas flow rates throughout the welding process.

8. Heat Input Control:

- Control heat input carefully to prevent excessive grain growth or embrittlement of the titanium.

- Use pulsed welding techniques if necessary to minimize heat input while maintaining adequate penetration.

- Allow proper cooling between passes in multi-pass welds.

9. Post-Weld Treatment:

- Remove any residual oxide layer or discoloration using mechanical or chemical cleaning methods.

- Perform post-weld heat treatment if required by the specific titanium grade or application.

- Conduct non-destructive testing (NDT) such as radiographic or ultrasonic inspection to verify weld integrity.

10. Quality Control:

- Implement a comprehensive quality control process, including visual inspection, dimensional checks, and leak testing.

- Document all welding parameters, material traceability, and inspection results for future reference.

11. Corrosion Prevention:

- If the titanium flange will be in contact with dissimilar metals, use appropriate isolation techniques to prevent galvanic corrosion.

- Consider the use of protective coatings or wraps in highly corrosive environments.

12. Handling and Storage:

- Handle installed flanges with care to prevent damage to the welded joint or flange surface.

- Protect open flange faces with appropriate covers during system downtime or storage.

13. Maintenance:

- Develop and follow a regular inspection and maintenance schedule to ensure the continued integrity of the flange connection.

- Address any signs of corrosion, leakage, or joint deterioration promptly.

14. Training and Certification:

- Ensure that all personnel involved in the installation process are properly trained and certified for working with titanium and socket weld flanges.

- Stay updated on industry standards and best practices related to titanium welding and flange installation.

By adhering to these best practices, the installation of titanium socket weld flanges can be carried out effectively, ensuring a robust and reliable connection in the piping system. It's important to note that specific procedures may vary depending on the exact titanium grade, application requirements, and relevant industry standards. Always consult manufacturer guidelines and applicable codes when installing titanium socket weld flanges.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM B381 - Standard Specification for Titanium and Titanium Alloy Forgings

2. ASME B16.5 - Pipe Flanges and Flanged Fittings

3. AWS D1.9/D1.9M - Structural Welding Code - Titanium

4. NACE MR0175/ISO 15156 - Materials for use in H2S-containing environments in oil and gas production

5. Titanium Information Group. (2022). Welding of Titanium and its Alloys - Part 1

6. American Welding Society. (2021). Welding Handbook, Volume 4: Materials and Applications, Part 2

7. Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International

8. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons

9. Lütjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media

10. Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials Properties Handbook: Titanium Alloys. ASM International