- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

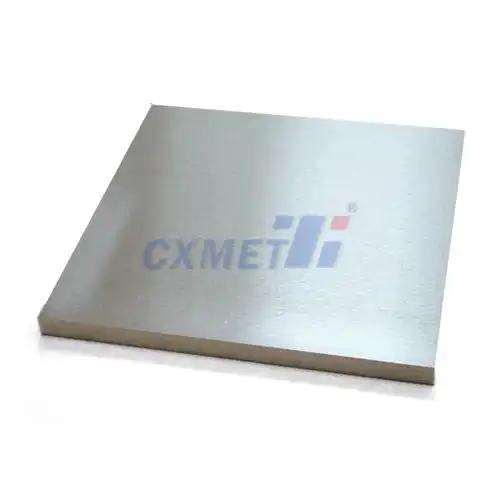

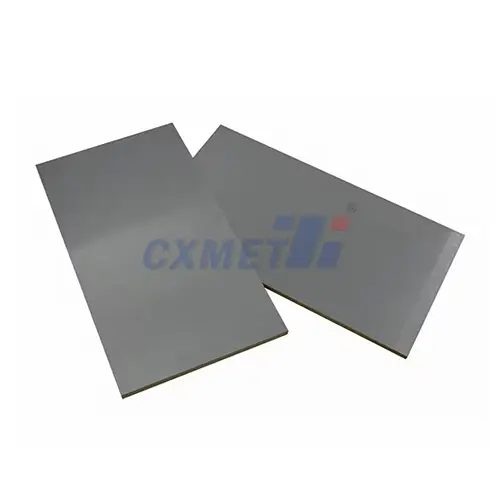

What is Titanium 3Al-2.5V Grade 9 Sheet?

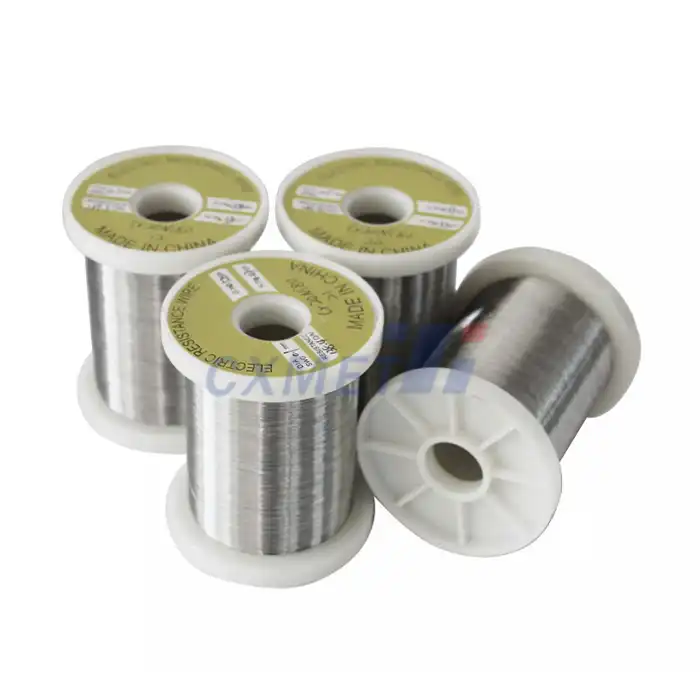

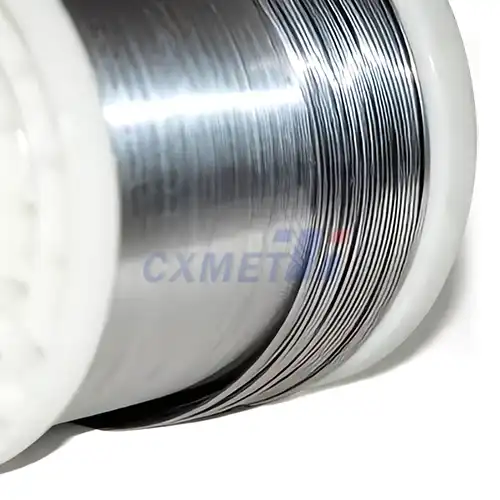

Titanium 3Al-2.5V Grade 9 Sheet, also known as Ti-3-2.5 or UNS R56320, is a high-strength alpha-beta titanium alloy that combines excellent mechanical properties with good formability and weldability. This versatile material is widely used in aerospace, medical, and industrial applications due to its unique combination of strength, lightweight characteristics, and corrosion resistance. The alloy composition consists of 3% aluminum and 2.5% vanadium, with the balance being titanium. This specific formulation results in a material that offers superior performance in various demanding environments.

What are the properties of Titanium 3Al-2.5V Grade 9?

Titanium 3Al-2.5V Grade 9 is renowned for its exceptional blend of physical and mechanical properties, making it a preferred choice for many critical applications. Let's delve into the key characteristics that set this alloy apart:

1. Strength-to-Weight Ratio: One of the most notable features of Ti-3-2.5 is its impressive strength-to-weight ratio. With a density of approximately 4.48 g/cm³, it is significantly lighter than many steel alloys while maintaining comparable or superior strength. This property makes it ideal for applications where weight reduction is crucial, such as in aerospace components or high-performance sporting goods.

2. Mechanical Properties: Grade 9 titanium exhibits excellent mechanical properties, including high tensile strength, good ductility, and fatigue resistance. In the annealed condition, it typically has a tensile strength of around 620 MPa (90 ksi) and a yield strength of about 485 MPa (70 ksi). These values can be further improved through heat treatment and cold working processes.

3. Corrosion Resistance: Like other titanium alloys, Ti-3-2.5 demonstrates outstanding corrosion resistance in various environments. It forms a stable, protective oxide layer on its surface, which provides excellent resistance to saltwater, marine atmospheres, and many industrial chemicals. This makes it suitable for use in offshore oil and gas applications, chemical processing equipment, and marine hardware.

4. Temperature Performance: Grade 9 titanium maintains its mechanical properties over a wide temperature range. It performs well at both cryogenic temperatures and in moderately elevated temperature environments, with a maximum service temperature of around 427°C (800°F). This temperature stability contributes to its popularity in aerospace applications, where components may be exposed to extreme temperature variations.

5. Formability and Weldability: Compared to some other titanium alloys, Ti-3-2.5 offers improved formability, making it easier to shape into complex geometries. It can be cold-formed using conventional techniques and is readily weldable using various methods, including TIG (Tungsten Inert Gas) welding and electron beam welding. These characteristics make it particularly suitable for manufacturing intricate parts and structures.

6. Biocompatibility: The alloy's excellent biocompatibility has led to its widespread use in medical implants and surgical instruments. Its non-toxic nature and resistance to body fluids make it safe for long-term contact with human tissue, contributing to its popularity in orthopedic and dental applications.

7. Fatigue Resistance: Ti-3-2.5 demonstrates superior fatigue resistance compared to many other metallic materials. This property is crucial in applications involving cyclic loading, such as aircraft components and high-performance automotive parts, where long-term reliability is essential.

8. Low Modulus of Elasticity: With a modulus of elasticity of around 100 GPa, Grade 9 titanium is more flexible than steel while still maintaining high strength. This characteristic can be advantageous in applications requiring some degree of elasticity, such as in certain medical implants or spring components.

Understanding these properties is crucial for engineers and designers when selecting materials for specific applications. The unique combination of strength, lightweight nature, and corrosion resistance makes Titanium 3Al-2.5V Grade 9 an excellent choice for a wide range of high-performance applications across various industries.

How is Titanium 3Al-2.5V Grade 9 Sheet manufactured?

The production of Titanium 3Al-2.5V Grade 9 Sheet involves a complex series of processes that require precision and expertise. Understanding this manufacturing process is essential for appreciating the material's quality and performance characteristics. Let's explore the key steps involved in creating this high-performance titanium alloy sheet:

1. Raw Material Preparation: The process begins with the careful selection and preparation of raw materials. Pure titanium sponge is combined with aluminum and vanadium in precise proportions to achieve the desired 3Al-2.5V composition. The exact ratios and purity of these elements are critical in ensuring the final product meets the required specifications.

2. Melting and Ingot Formation: The prepared raw materials are then melted in a vacuum or inert gas environment to prevent contamination. This is typically done using Vacuum Arc Remelting (VAR) or Electron Beam Melting (EBM) techniques. These methods ensure the removal of impurities and the homogenization of the alloy composition. The molten metal is then cast into large ingots.

3. Primary Hot Working: The ingots undergo primary hot working processes such as forging or rolling at high temperatures. This step helps to break down the as-cast structure and improve the material's overall properties. The temperature and deformation rates are carefully controlled to achieve the desired microstructure.

4. Secondary Processing: The material then undergoes secondary processing, which may include further hot rolling or forging operations. These steps are crucial in refining the grain structure and achieving the desired mechanical properties. The material may be processed into various intermediate forms such as billets or slabs at this stage.

5. Sheet Formation: To produce the final sheet form, the material undergoes a series of rolling operations. This typically involves both hot and cold rolling processes. Hot rolling is performed at elevated temperatures to reduce the thickness of the material while maintaining workability. Cold rolling is then used to achieve the final thickness and surface finish.

6. Heat Treatment: Heat treatment plays a vital role in optimizing the mechanical properties of the Ti-3-2.5 sheet. Common heat treatments include annealing, solution treating, and aging. These processes help to relieve internal stresses, refine the microstructure, and enhance strength and ductility.

7. Surface Treatment: The sheet may undergo various surface treatments to enhance its properties further. These can include chemical milling to remove the alpha case (a brittle oxygen-rich layer that forms during high-temperature processing), pickling to remove surface oxides, and passivation to improve corrosion resistance.

8. Quality Control and Testing: Throughout the manufacturing process, rigorous quality control measures are implemented. This includes chemical analysis to verify composition, mechanical testing to ensure properties meet specifications, and non-destructive testing (such as ultrasonic inspection) to detect any internal defects.

9. Finishing and Sizing: The final steps involve cutting the sheets to the required dimensions and performing any necessary finishing operations. This may include edge trimming, leveling, and surface finishing to meet customer specifications.

10. Packaging and Shipping: The finished sheets are carefully packaged to protect them during transportation and storage. Special care is taken to prevent surface damage and contamination.

The manufacturing process of Titanium 3Al-2.5V Grade 9 Sheet is a testament to the advanced metallurgical techniques employed in the production of high-performance materials. Each step is carefully controlled and monitored to ensure the final product meets the stringent requirements of aerospace, medical, and industrial applications. The complex nature of this process contributes to the material's cost but also ensures its exceptional quality and reliability in critical applications.

What are the applications of Titanium 3Al-2.5V Grade 9 Sheet?

Titanium 3Al-2.5V Grade 9 Sheet finds widespread use across various industries due to its exceptional combination of properties. Its versatility makes it a preferred material for numerous applications where high strength, low weight, and excellent corrosion resistance are essential. Let's explore some of the key areas where this remarkable alloy is utilized:

1. Aerospace Industry:

The aerospace sector is one of the primary consumers of Ti-3-2.5 sheet. Its high strength-to-weight ratio and excellent fatigue resistance make it ideal for aircraft components. Some specific applications include:

- Hydraulic tubing systems in commercial and military aircraft

- Airframe structures and components

- Engine parts, such as compressor blades and casings

- Exhaust system components

- Fasteners and fittings

2. Medical and Dental Applications:

The biocompatibility and corrosion resistance of Grade 9 titanium make it an excellent choice for various medical applications:

- Surgical implants, including bone plates and screws

- Dental implants and prosthetics

- Medical instruments and devices

- Orthopedic joint replacements

3. Chemical Processing Industry:

The alloy's exceptional resistance to corrosion in various chemical environments makes it valuable in chemical processing equipment:

- Heat exchangers and condensers

- Reaction vessels and storage tanks

- Valves and pumps for handling corrosive fluids

- Piping systems in chemical plants

4. Marine and Offshore Applications:

Ti-3-2.5's resistance to saltwater corrosion makes it ideal for marine environments:

- Underwater equipment and structures

- Propeller shafts and marine propulsion components

- Desalination plant components

- Offshore oil and gas equipment

5. Automotive Industry:

While not as widely used as in aerospace, the automotive sector employs Ti-3-2.5 in high-performance applications:

- Racing car components

- High-performance engine parts

- Exhaust systems

- Suspension components in luxury and sports vehicles

6. Sports and Recreation:

The alloy's strength and lightweight nature make it popular in sporting goods:

- Golf club heads and shafts

- Bicycle frames and components

- Tennis racket frames

- High-end watch cases and components

7. Industrial Applications:

Various industrial sectors benefit from the unique properties of Ti-3-2.5:

- Pressure vessels for demanding environments

- Cryogenic storage tanks

- Architectural cladding and roofing in corrosive environments

- High-performance springs and fasteners

8. Energy Sector:

The alloy finds applications in both traditional and renewable energy industries:

- Components for geothermal power plants

- Solar panel support structures in coastal areas

- Parts for wind turbines exposed to marine environments

- Heat exchangers in power generation facilities

9. Space Exploration:

In space applications, where weight savings are critical, Ti-3-2.5 is used in:

- Spacecraft structural components

- Propulsion system parts

- Satellite components

- Space station elements

10. Defense Industry:

Military applications leverage the alloy's properties for:

- Armor plating and ballistic protection

- Missile components

- Naval vessel parts exposed to seawater

- Military aircraft components

The wide range of applications for Titanium 3Al-2.5V Grade 9 Sheet demonstrates its versatility and the value it brings to various industries. Its unique combination of properties - high strength, low density, excellent corrosion resistance, and biocompatibility - make it an indispensable material in modern engineering and manufacturing. As technology advances and new challenges emerge, this exceptional alloy is likely to find even more innovative applications across diverse fields.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASM International. (2015). ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

2. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons.

3. Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

4. Lutjering, G., & Williams, J. C. (2007). Titanium (Engineering Materials and Processes). Springer.

5. ASTM International. (2021). ASTM B265 - Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate.

6. Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

7. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

8. Froes, F. H. (Ed.). (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

9. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

10. Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.