- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

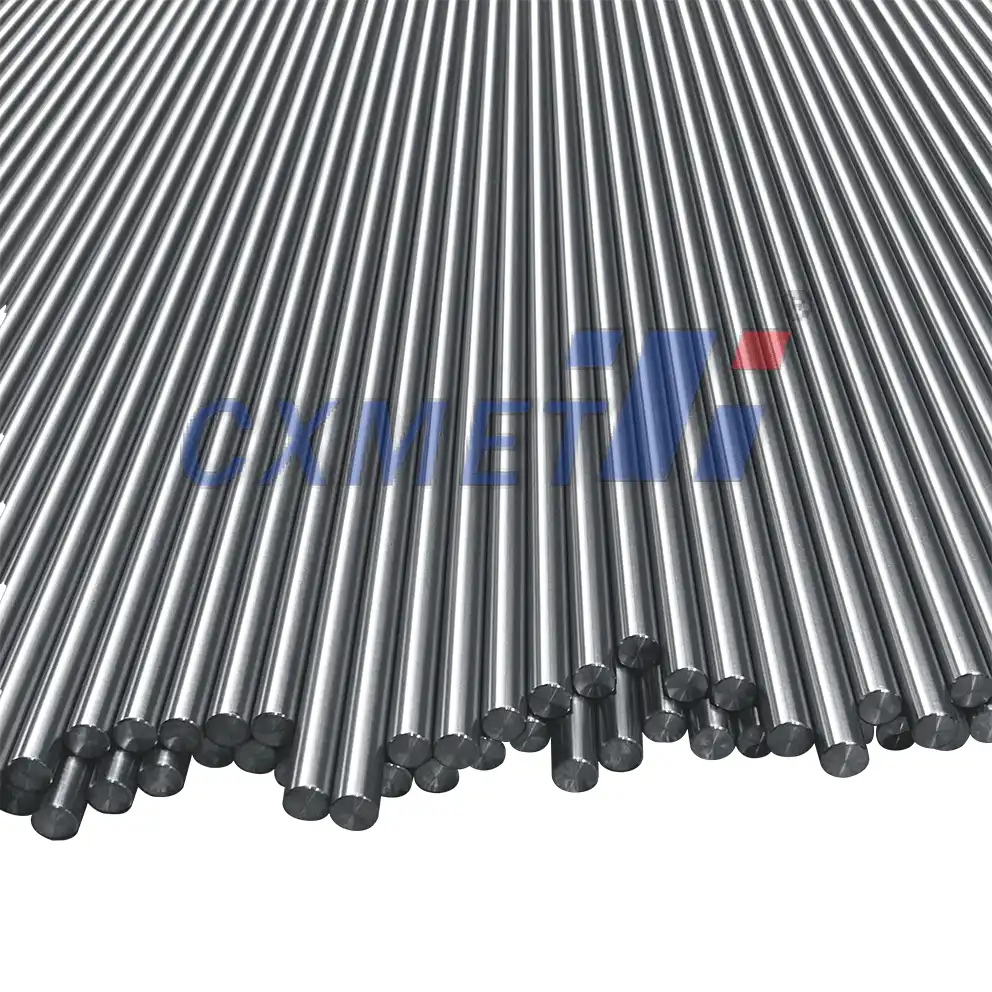

5mm zirconium bar

Brand Name: CXMET

Place of Origin: China

Shape: Round

Material: Pure zirconium

Diameter 6mm-40mm

Production technology: Cutting heat treatment forming

Apply: Materials for fuel elements

Shape: Round

Color: Sliver

Introducing the 5mm Zirconium Bar from Shaanxi CXMET Technology Co., Ltd., a leading manufacturer and supplier of high-performance zirconium products. At Shaanxi CXMET Technology Co., Ltd., we specialize in producing high-quality zirconium bars that meet the stringent requirements of our global clientele.

Our 5mm zirconium bar is meticulously manufactured to ensure superior quality and consistency.Our advanced facilities and a team of over 80 skilled technicians ensure we consistently deliver high-performance, reliable products that surpass expectations.

Product Parameters

The following table provides the detailed parameters of our 5mm zirconium bar:

| Parameter | Specification |

|---|---|

| Diameter | 5mm |

| Length | Up to 3000mm |

| Purity | ≥ 99.5% |

| Density | 6.52 g/cm³ |

| Melting Point | 1855°C |

| Tensile Strength | 330 MPa |

| Yield Strength | 275 MPa |

| Elongation | 20% |

|

|

|

|

|

|

Physical and Chemical Properties

Zirconium possesses several noteworthy physical and chemical properties:

- Corrosion Resistance: Exceptional resistance to corrosion in most acidic and alkaline environments.

- High Melting Point: A melting point of 1855°C, suitable for high-temperature applications.

- Density: Relatively low density at 6.52 g/cm³, contributing to its lightweight yet robust nature.

- Non-toxic and Biocompatible: Safe for use in medical and dental applications.

Product Functions

- Corrosion Resistance: The 5mm zirconium bar is highly resistant to corrosion, making it suitable for use in harsh chemical environments, including acid and alkali conditions.

- High-Temperature Stability: With a high melting point, zirconium bars can withstand extreme temperatures, making them ideal for applications in the aerospace and nuclear industries.

- Mechanical Strength: The excellent tensile and yield strength of zirconium ensures durability and reliability in demanding applications.

- Biocompatibility: Its non-toxic nature makes zirconium a preferred material for medical implants and devices.

Product Applications

- Chemical Processing: Used in reactors, tanks, and piping systems due to its outstanding resistance to corrosion from aggressive chemicals.

- Aerospace Industry: Ideal for high-temperature applications in jet engines and other aerospace components.

- Nuclear Industry: Utilized in fuel rods and other components in nuclear reactors because of its low neutron-capture cross-section.

- Medical Devices: Perfect for surgical instruments and implants due to its biocompatibility and non-toxic properties.

- Electronics: Used in semiconductor devices and electronic components due to its stable physical properties.

Product Manufacturing Process

- Raw Material Selection: High-purity zirconium is sourced and inspected to ensure quality.

- Melting and Casting: The zirconium is melted in a vacuum arc furnace to achieve homogeneity and eliminate impurities.

- Hot and Cold Working: The cast zirconium is subjected to hot and cold working processes to achieve the desired dimensions and mechanical properties.

- Precision Machining: The bars are precisely machined to meet exact specifications.

- Quality Control: Rigorous testing and inspection are conducted at each stage to ensure compliance with industry standards.

Company Introduction

Founded in 2005, Shaanxi CXMET Technology Co., Ltd. has grown into a leading manufacturer of titanium, nickel, tantalum, niobium, tungsten, molybdenum, zirconium, and their alloys. Located in the "China Titanium Valley," our company covers an area of 50,000 square meters and boasts a registered capital of 10 million. Our commitment to innovation and quality has positioned us as a trusted supplier in the global market.

Logistics and Packaging

- Wooden Crate Packaging: Ensures maximum protection during transportation.

- Carton Packaging: Suitable for smaller quantities or lighter products.

- Foam Filling Packaging: Provides cushioning to prevent damage.

- Waterproof and Moisture-proof Packaging: Protects products from environmental elements.

- Customized Packaging: Tailored solutions to meet specific customer requirements.

- International Standard Packaging: Complies with global shipping standards.

Logistics Options

- Sea Freight: Economical for large shipments.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Flexible and cost-effective for regional deliveries.

- Multimodal Transport: Combination of sea, air, and land for optimized logistics.

- Express Services: Quick and reliable for small parcels.

Why Choose Us

- High Quality: Commitment to the highest standards of quality and precision.

- Advanced Equipment: State-of-the-art manufacturing facilities.

- Professional Team: Over 80 skilled technicians and experts.

- One-Stop Solution: Comprehensive services from material selection to final delivery.

OEM/ODM Services

Shaanxi CXMET Technology Co., Ltd. offers comprehensive OEM and ODM services, allowing customization of zirconium bars to meet specific client requirements. We support custom sizes, shapes, and specifications to ensure our products perfectly fit your needs.

FAQ

- What is the purity of your zirconium bars?

- Our zirconium bars have a purity of ≥ 99.5%.

- Can you provide custom sizes?

- Yes, we offer customized dimensions to meet your specific requirements.

- What industries use zirconium bars?

- Industries such as chemical processing, aerospace, nuclear, medical, and electronics.

- How do you ensure product quality?

- We implement rigorous quality control measures at every stage of production.

- What are your shipping options?

- We provide sea, air, land, multimodal, and express shipping services.

Contact Us

Ready to explore the exceptional properties of our 5mm zirconium bar? Contact Shaanxi CXMET Technology Co., Ltd. today at SALES@CXMET.COM to discuss your requirements. Our team is eager to assist you in finding the perfect solution for your application. Let's collaborate to bring your projects to life with high-quality zirconium products.

hotTags:5mm zirconium bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Ti13Nb13Zr Rod

Brand: CXMET

Place Of Origin: China

Classification:Round/Square/Hexagon

Standard:ASTM B348,ASTM F67,ASTM F136,ASME SB348

Grade: Gr1-Gr7,Gr5,Gr5 Eli,Gr12

Size: Dia(0.8mm-100mm)*Length(≤3000mm)

Processing Method:Forging/Extrusion/Rolling/Cold drawing

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements

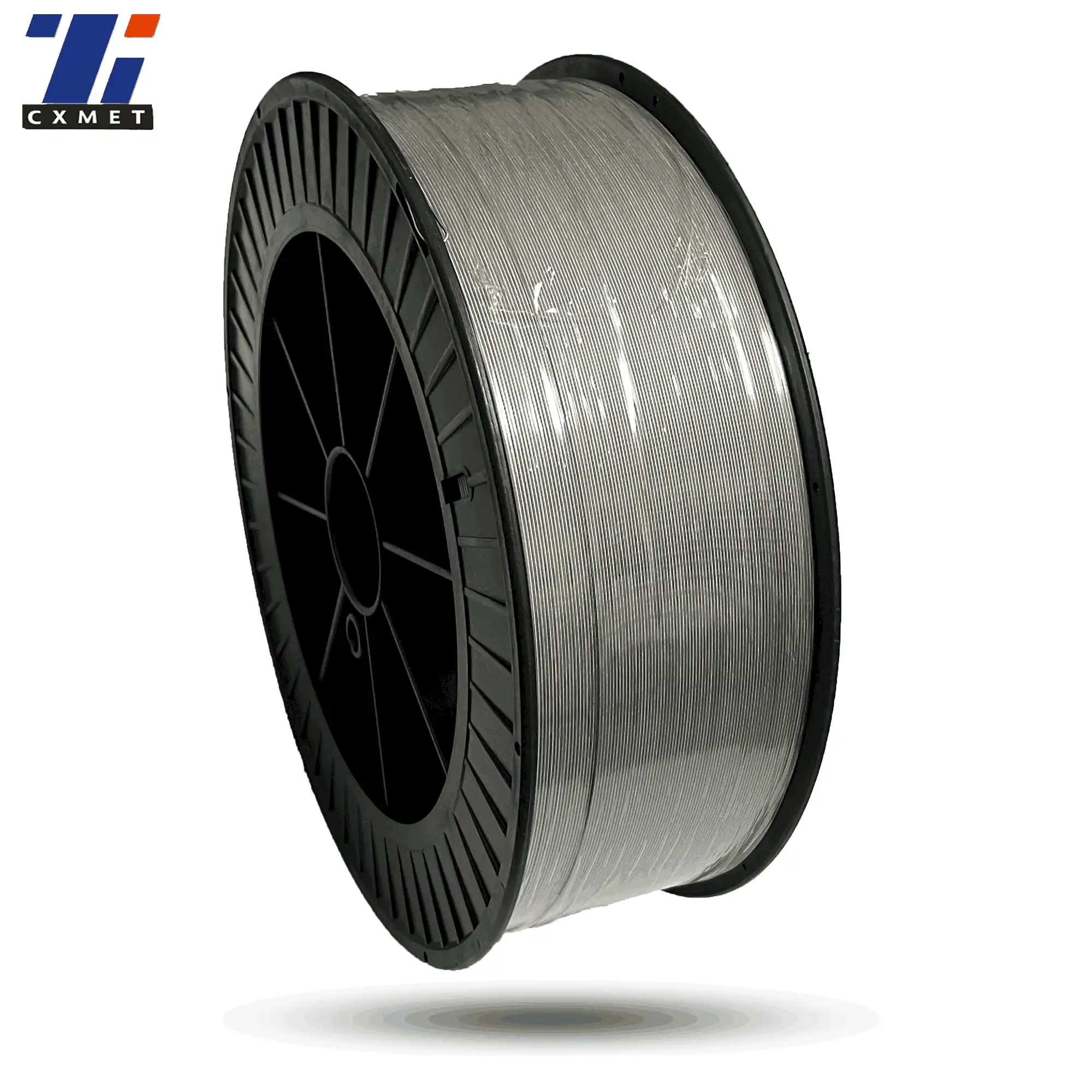

hafnium wire

"Product Name:99.9% High purity hafnium wire Place of Origin: china Brand Name: CXMET purity: 99.99% Composition: Hafnium Product Type:Hafnium alloy products Content(percent) 99.9-99.99% Package:Standard wooden case "

View More

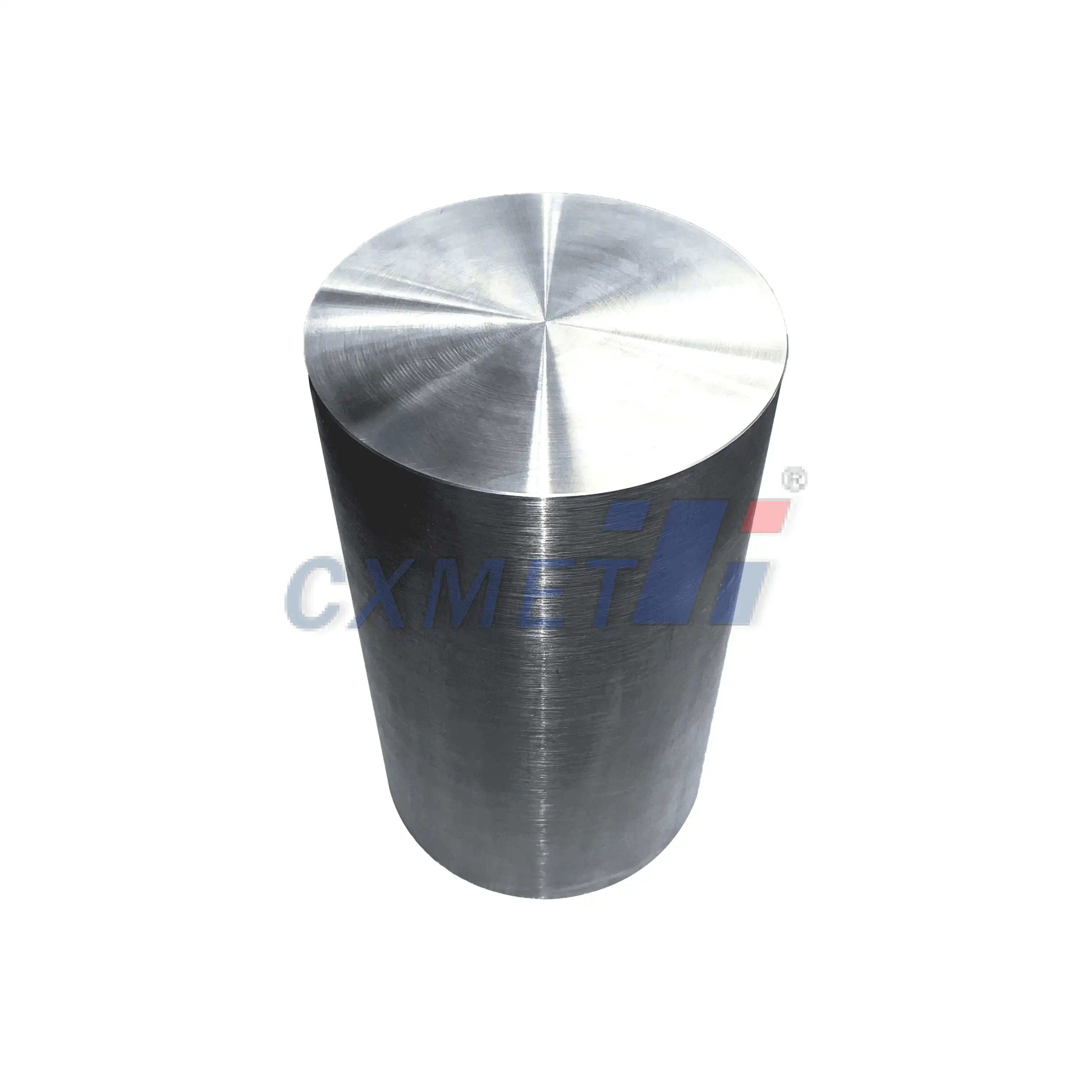

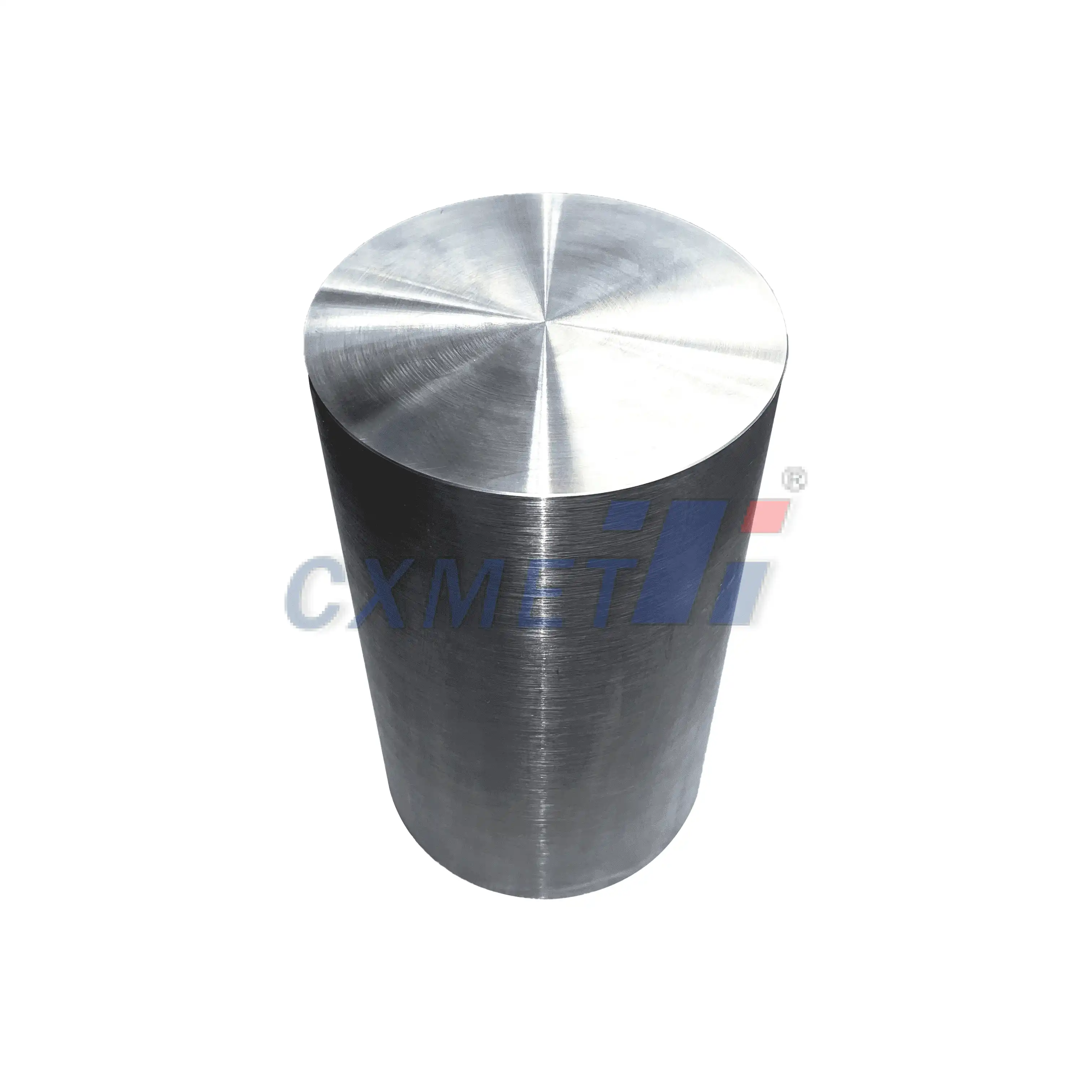

Crystal hafnium metal rod

Product Name:Crystal hafnium metal rod

Place of Origin: China

Brand Name: CXMET

Model Number: Hf-1

Shape: Rod

Material: Hafnium Metal

Chemical Composition: Hafnium

Purity ≥99.99%

Hafnium oxide HfO2 tablet

Product name: Hafnium oxide HfO2 granule/tablet for vacuum coating

Brand Name: CXMET

Place of Origin: China

Application: Vacuum coating

Shape: Granule/Tablet

Color: Black

Purity: 99.99%

Density: 9.68g/cm3

Melting Point(°C): 2810

zirconium crucible

Brand: CXMET

Place of Origin: China

Material: Zirconium

Shape: Crucible

Purity: 99.2%

Size:Customized

Certificate: ISO9001:2015

Surface: Grinding Polished

Zr702 Zirconium Rod

Product Name:China factory supply Zr702 Zirconium Rod/wire

Brand Name: CXMET

Place of Origin: China

Shape: Round bar

Material: Zirconium

Chemical Composition: Zirconium

Usage: Industrial

Certificate: ISO9001

hafnium sputtering target

Product name: Hot sale hafnium sputtering target

Brand Name: CXMET

Place of Origin: China

Shape: Sheet, Foil

Material: Hafnium

Chemical Composition: 99.99% Hafnium

Purity 99.99%

Density 13.31 g/cm³

Usage: Aerospace, Electronics, Nuclear, etc.

Color: Metal grey