- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

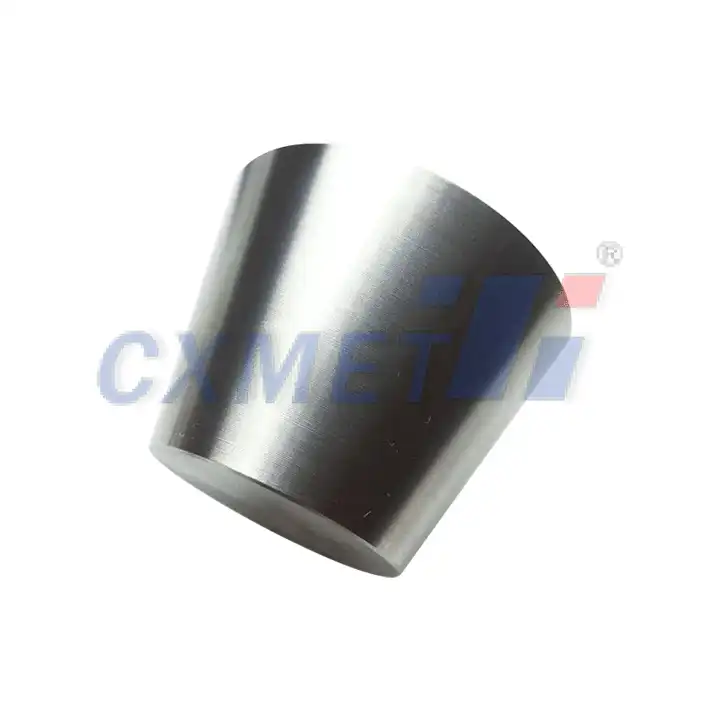

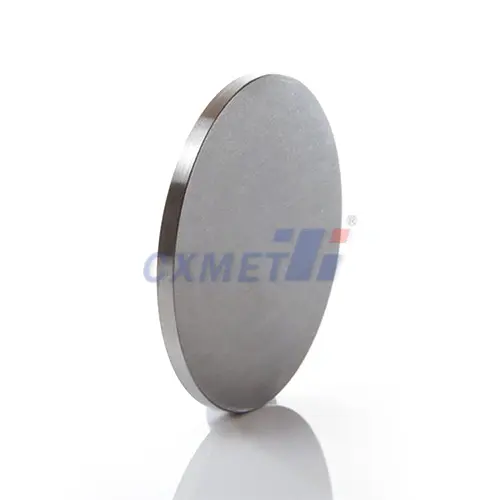

zirconium crucible

Place of Origin: China

Material: Zirconium

Shape: Crucible

Purity: 99.2%

Size:Customized

Certificate: ISO9001:2015

Surface: Grinding Polished

Zirconium crucibles are essential in industries that demand materials capable of withstanding extreme conditions. As a leading supplier, Shaanxi CXMET Technology Co., Ltd. offers top-quality zirconium crucibles known for their exceptional thermal stability, corrosion resistance, and mechanical strength. These properties make them indispensable in high-temperature environments, such as metallurgy, chemical processing, and advanced material research. With over 20 years of industry experience, Shaanxi CXMET Technology Co., Ltd. is committed to providing superior products and services to meet the rigorous demands of our global clientele.

Our zirconium crucibles are manufactured using advanced technology and stringent quality control processes. This ensures that every product meets the highest industry standards. Our extensive expertise in zirconium and other refractory metals allows us to offer tailored solutions to our customers, enhancing their operational efficiency and productivity. As a trusted partner, we strive to deliver unparalleled value, backed by our comprehensive support and professional service.

Product Parameters

| Parameter | Specification |

|---|---|

| Material Purity | ≥ 99.95% |

| Density | 6.49 g/cm³ |

| Melting Point | 1855°C |

| Boiling Point | 4377°C |

| Maximum Operating Temperature | 2200°C |

| Standard Sizes | 10ml, 50ml, 100ml, 250ml, 500ml |

|

|

|

|

|

|

|

|

|

Physicochemical Properties

Zirconium is renowned for its high melting point, excellent corrosion resistance, and mechanical properties. These characteristics are crucial for applications involving extreme temperatures and reactive environments. The physicochemical properties of zirconium crucibles include:

- High Melting Point: 1855°C, enabling use in high-temperature processes.

- Excellent Corrosion Resistance: Resistant to most acids and alkalis, extending the crucible's lifespan.

- High Mechanical Strength: Maintains structural integrity under thermal stress.

- Low Thermal Expansion: Minimizes deformation and cracking under thermal cycling.

Product Functions

Our zirconium crucibles offer several key functions, making them ideal for various industrial applications:

- High-Temperature Resistance: Capable of withstanding extreme temperatures without degrading, essential for processes like metal melting and crystal growth.

- Chemical Stability: Resists reactions with most chemicals, ensuring purity of the materials being processed.

- Durability: High mechanical strength and resistance to thermal shock provide long-lasting performance.

- Purity Maintenance: Low impurity levels prevent contamination of the processed materials, crucial for high-purity applications.

Product Applications

The unique properties of zirconium crucibles make them suitable for a wide range of applications:

- Metallurgy: Used for melting and casting high-purity metals and alloys.

- Chemical Processing: Ideal for handling corrosive chemicals and high-temperature reactions.

- Material Science: Employed in the development and testing of new materials requiring high-purity conditions.

- Electronics: Utilized in the production of semiconductors and other electronic components.

- Nuclear Industry: Serves in the processing of nuclear materials due to its low neutron absorption cross-section.

Manufacturing Process and Production Flow

Our zirconium crucibles are produced through a meticulous process involving:

- Material Selection: High-purity zirconium is sourced and verified for quality.

- Forming: The material is shaped into crucibles using precision techniques.

- Sintering: Crucibles are sintered at high temperatures to enhance their structural integrity.

- Machining: Final dimensions and surface finishes are achieved through careful machining.

- Quality Control: Each crucible undergoes rigorous testing to ensure it meets our strict standards.

Factory Introduction

Founded in 2005, Shaanxi CXMET Technology Co., Ltd. is located in the "China Titanium Valley." Our facility covers 50,000 square meters and houses advanced equipment and a professional team of over 80 technicians. We specialize in the production of titanium, nickel, tantalum, niobium, tungsten, molybdenum, zirconium, and their alloys. Our commitment to innovation and excellence has positioned us as a leader in the field, providing high-quality products to various industries worldwide.

Packaging and Logistics

Packaging

- Wooden Crates: Provides robust protection for large shipments.

- Cardboard Boxes: Suitable for smaller, lighter items.

- Foam Padding: Ensures cushioning and protection against shocks.

- Waterproof and Moisture-Proof Packaging: Prevents damage from environmental factors.

- Custom Packaging: Tailored solutions to meet specific customer requirements.

- International Standards: All packaging complies with international shipping regulations.

Logistics

- Sea Freight: Cost-effective for large and heavy shipments.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Efficient for regional deliveries.

- Multimodal Transport: Combines various transportation modes for optimal efficiency.

- Express Services: Rapid delivery for small, time-sensitive orders.

Why Choose Us

Choosing Shaanxi CXMET Technology Co., Ltd. means benefiting from:

- High Quality: We adhere to the highest standards of quality control.

- Advanced Equipment: Our state-of-the-art machinery ensures precision and consistency.

- Professional Team: Our experienced technicians provide expert support and solutions.

- One-Stop Solution: Comprehensive services from material selection to final delivery.

- Customization: OEM/ODM services tailored to meet specific requirements.

- Global Reach: Extensive experience in international markets and logistics.

OEM/ODM Services

At Shaanxi CXMET Technology Co., Ltd., we offer comprehensive OEM/ODM services, allowing customers to customize their zirconium crucibles according to their specific needs. Our capabilities include custom dimensions, shapes, and purity levels. Our team works closely with clients to ensure that their requirements are met with precision and efficiency.

Frequently Asked Questions (FAQ)

-

What is the purity level of your zirconium crucibles?

- Our zirconium crucibles have a purity level of ≥ 99.95%, ensuring high performance and reliability.

-

Can you produce custom-sized crucibles?

- Yes, we offer OEM services and can produce crucibles according to your specific dimensions and requirements.

-

What is the maximum operating temperature for your zirconium crucibles?

- The maximum operating temperature is 2200°C, making them suitable for high-temperature applications.

-

How do you ensure the quality of your crucibles?

- Our crucibles undergo rigorous quality control processes, including material verification, dimensional checks, and performance testing.

-

What packaging options are available?

- We offer various packaging options, including wooden crates, cardboard boxes, foam padding, and custom packaging solutions.

Contact Us

We invite global purchasers to collaborate with Shaanxi CXMET Technology Co., Ltd. for high-quality zirconium crucibles and other refractory metal products. Our commitment to excellence and customer satisfaction makes us the ideal partner for your needs. Contact us today at SALES@CXMET.COM to discuss your requirements and discover how we can support your business.

hotTags:zirconium crucible,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

titanium sputtering target

Brand: CXMET

Place Of Origin: China

Material: Titanium

Type Laser Machining, Milling, Other Machining Services, Turning, Wire EDM

Micro Machining or Not Not Micro Machining

Material: Pure Titanium

Size: Custom

Color: Black

Shape: Round ,Sheet

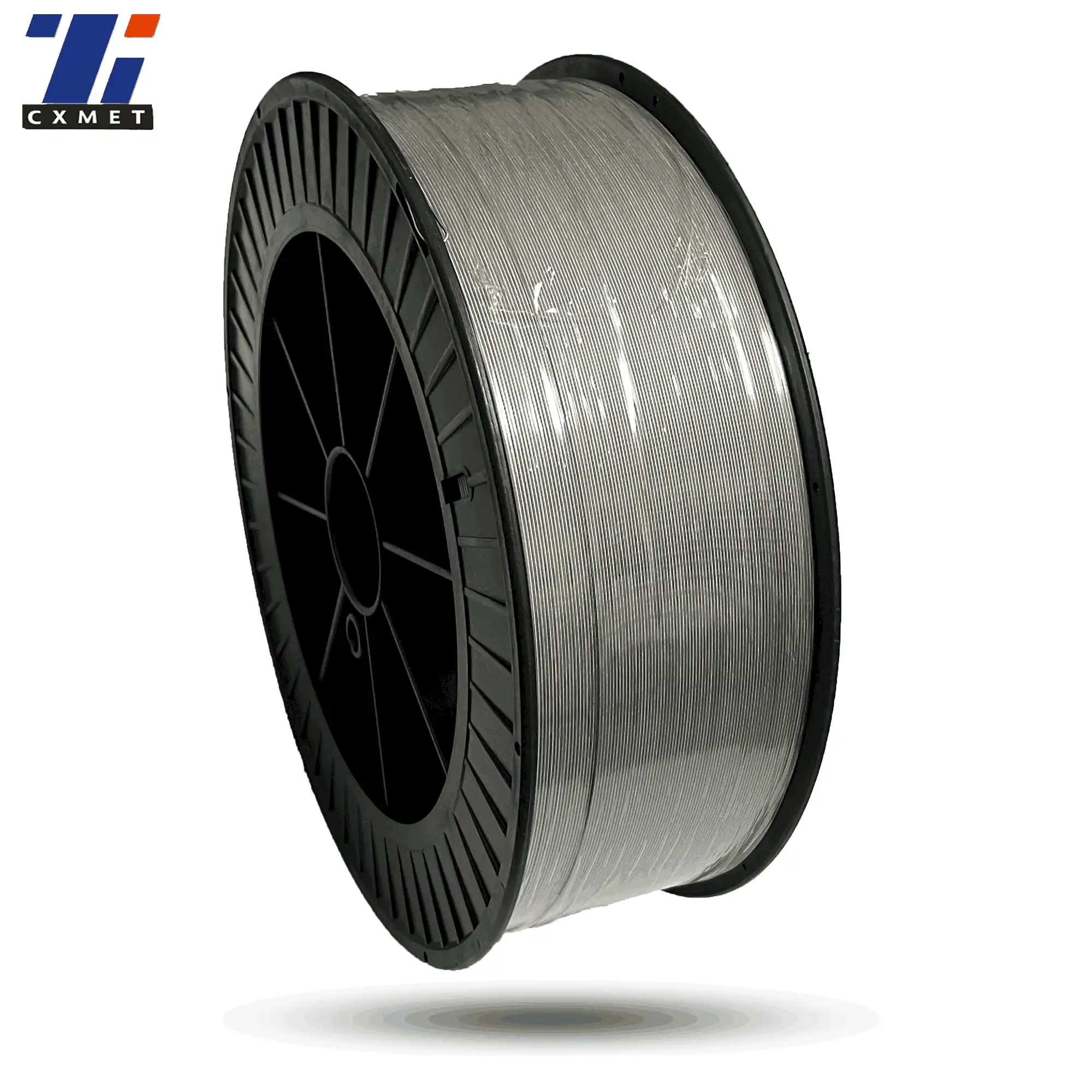

gr4 titanium wire

Brand: CXMET

Place Of Origin: China

Specifications: ASTM B863 ASME SB863

Dimensions: ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360

Length: 100 mm TO 5500 mm

Diameter: 10 mm To 99 mm

Specialize: Filler Wire, Coil Wire, Electrode Wire, Welding Wire.

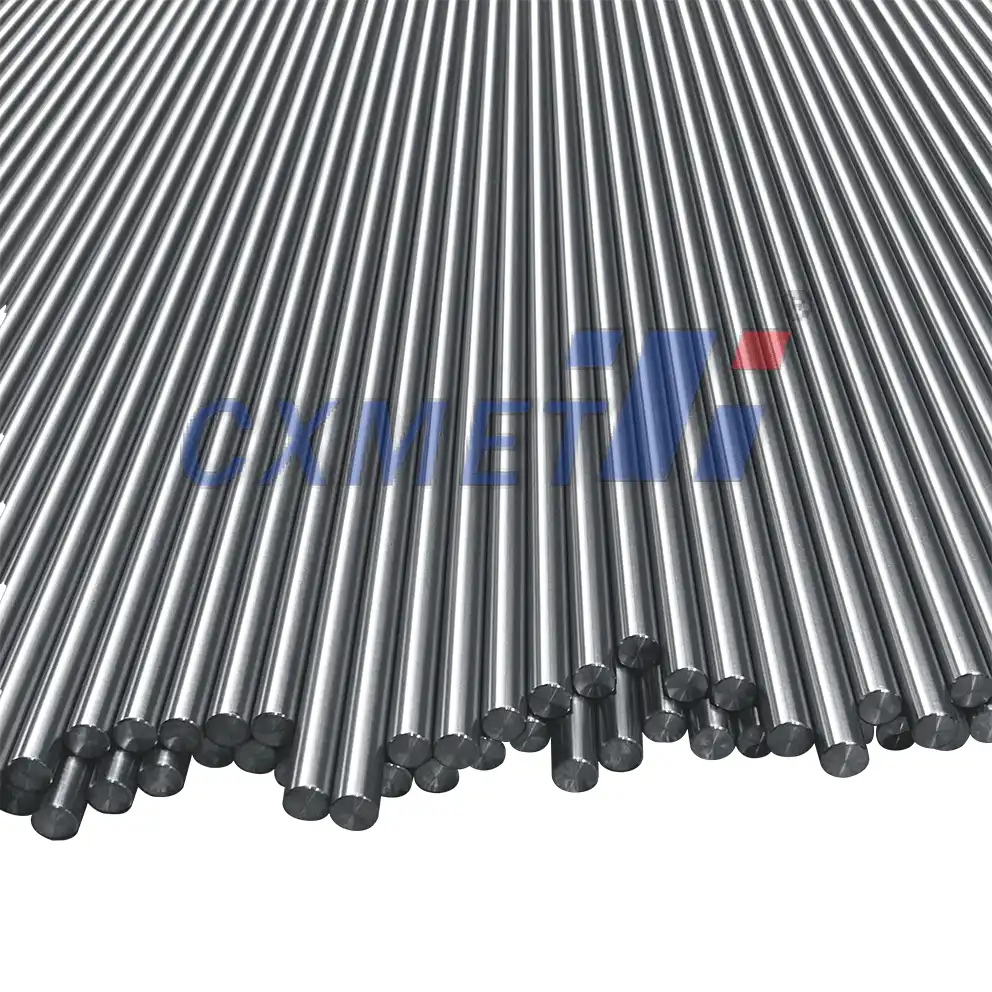

5mm zirconium bar

Product name: High quality zirconium rod

Brand Name: CXMET

Place of Origin: China

Shape: Round

Material: Pure zirconium

Diameter 6mm-40mm

Production technology: Cutting heat treatment forming

Apply: Materials for fuel elements

Shape: Round

Color: Sliver

hafnium wire

"Product Name:99.9% High purity hafnium wire Place of Origin: china Brand Name: CXMET purity: 99.99% Composition: Hafnium Product Type:Hafnium alloy products Content(percent) 99.9-99.99% Package:Standard wooden case "

View More

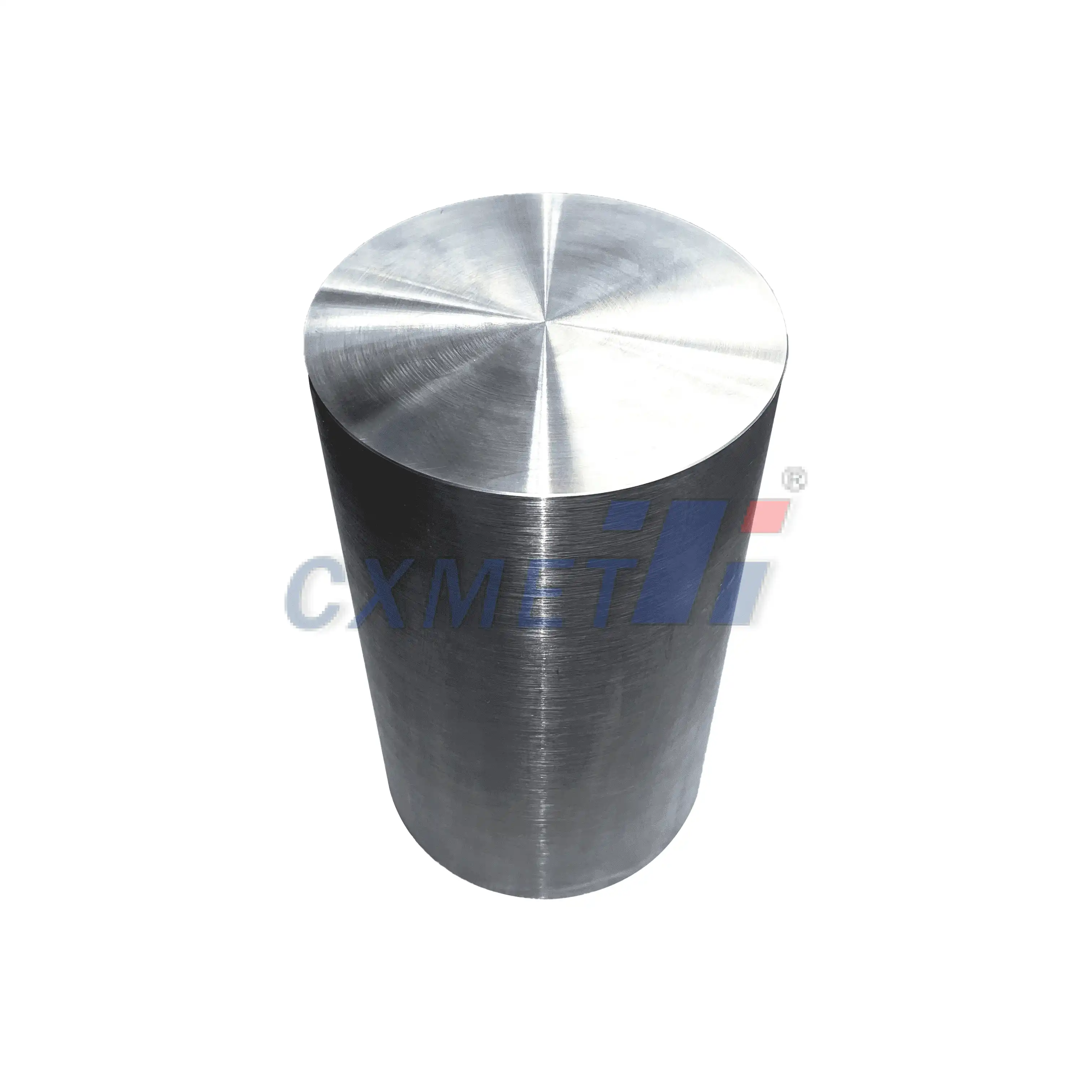

Crystal hafnium metal rod

Product Name:Crystal hafnium metal rod

Place of Origin: China

Brand Name: CXMET

Model Number: Hf-1

Shape: Rod

Material: Hafnium Metal

Chemical Composition: Hafnium

Purity ≥99.99%

Hafnium oxide HfO2 tablet

Product name: Hafnium oxide HfO2 granule/tablet for vacuum coating

Brand Name: CXMET

Place of Origin: China

Application: Vacuum coating

Shape: Granule/Tablet

Color: Black

Purity: 99.99%

Density: 9.68g/cm3

Melting Point(°C): 2810

Zr702 Zirconium Rod

Product Name:China factory supply Zr702 Zirconium Rod/wire

Brand Name: CXMET

Place of Origin: China

Shape: Round bar

Material: Zirconium

Chemical Composition: Zirconium

Usage: Industrial

Certificate: ISO9001

hafnium sputtering target

Product name: Hot sale hafnium sputtering target

Brand Name: CXMET

Place of Origin: China

Shape: Sheet, Foil

Material: Hafnium

Chemical Composition: 99.99% Hafnium

Purity 99.99%

Density 13.31 g/cm³

Usage: Aerospace, Electronics, Nuclear, etc.

Color: Metal grey

_1736153491879.webp)